News

Imagine you walk into your blacksmith workshop, ready to tackle a new project. You need a forge that heats fast, saves energy, and fits your main tasks. Start by listing what you want to create and the power level you need. Many blacksmiths now choose an induction forge because it offers precise control and boosts efficiency. The induction heating machine market keeps growing as shops invest more in technology and energy savings. Matching the right forge to your needs can improve heating accuracy by up to 10% and cut energy waste.

Key Takeaways

Induction forges heat metal quickly and precisely, saving energy and improving safety in your workshop.

Match the forge power and coil size to your main projects and metal types for the best results.

Choose a cooling system that fits your usage; water cooling works well for heavy use, while fan cooling suits smaller setups.

Check that your induction forge and heater are compatible to ensure efficient and reliable operation.

Use the step-by-step checklist to pick a forge that fits your needs, budget, and workspace safely and efficiently.

Induction Forge Basics

What Is an Induction Forge

An induction forge uses induction heating to warm metal for forging, shaping, or melting. You place the metal inside a coil. The coil carries an alternating electric current. This current creates a magnetic field. The field causes electric currents inside the metal. These currents heat the metal quickly and evenly.

You can use an induction forge for many tasks. Some blacksmiths use it for induction melting of metals like aluminum, copper, or iron. Others use it to heat bars or billets before shaping. Induction heating works fast and does not need direct contact with the metal. You only heat the part you want to work on. This keeps the rest of your workspace cooler and safer.

Note: Many users share stories about building their own induction forges. They talk about the challenges of coil design, insulation, and power supply. Some find it hard to control the circuits, but most agree that induction heating gives better results than traditional methods.

Key Benefits

You gain several advantages when you use an induction forge in your workshop:

Precise Temperature Control: Induction heating lets you set and hold exact temperatures. You get consistent results for every project.

High Efficiency: The forge heats only the metal you need. This saves energy and reduces waste. Some systems reach over 90% efficiency, much higher than gas or coal forges.

Faster Heating: Induction heating cuts cycle times by half or more. You spend less time waiting and more time working.

Improved Safety: The forge stays cool to the touch. Only the metal gets hot. This lowers the risk of burns and accidents.

Cleaner Workspace: Induction melting and forging do not produce smoke or open flames. Your shop stays cleaner and safer.

Many industries use induction forges for their speed and accuracy. For example, aerospace and automotive companies use them to make parts with tight tolerances. You can also use induction melting to recycle scrap metal or create custom alloys.

Assessing Workshop Needs

Image Source: pexels

Project Types

Before you choose a forge, you should think about the main tasks you do in your workshop. Every metalsmith and blacksmith has different needs. Some focus on blacksmithing, while others work on general metal projects. Here are some common project types where a forge can help:

Blacksmithing and tool making

General metalworking

Forging and casting parts

Sharpening blades or tools

Sheet metal working

Making bearings and springs

Working with metal tubing or copper piping

Building metal structures like brackets, wheels, or gates

Foundry work, such as casting engine crankcases

Smelting furnaces for heating metal

Welding, including arc and oxygen-acetylene welding

Fabricating parts from angle, channel, or plate iron

You might work with ferrous metals like steel or iron, or non-ferrous metals such as aluminum and copper. Each project type may need a different approach. For example, a blacksmith who shapes horseshoes will use the forge differently than a metalsmith who fabricates custom brackets.

Tip: Make a list of your most common projects. This will help you match the right forge to your needs.

Power Requirements

The power level of your forge matters. You need enough heat for your projects, but you also want to avoid wasting energy. Most hobbyists and small blacksmith shops find that a 15kW forge works well for basic blacksmithing, sharpening, and small casting jobs. If you are a professional metalsmith or run a busy shop, you may need a forge with 25kW or more. Large projects, like foundry work or heavy forging, often require even higher power.

You should also check the electrical supply in your workshop. Some forges need special wiring or higher voltage. Always match the forge power to your main project types and the metals you use most often.

Induction Forge Features

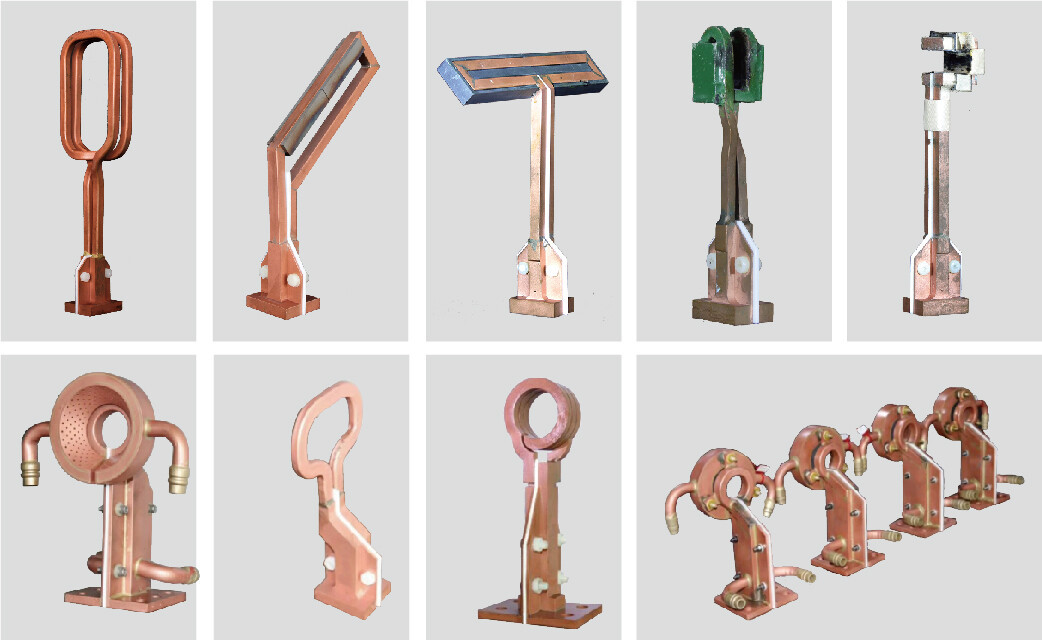

Coil Size and Shape

Choosing the right coil size and shape is one of the most important steps when setting up your forge. The coil must match the size and shape of the metal you want to heat. If you use a coil that is too large for your stock, the heating will be slow and uneven. If the coil is too small, it may not fit your material or could cause overheating.

You should keep about 5mm of space between the inside of the coil and your metal. This spacing helps the induction heater work at its best. For example, if you try to heat a ½ inch square mild steel bar with a large coil, you may not reach welding temperature. A smaller coil, sized just right for the bar, can heat it to welding temperature in under 30 seconds at full power. Oversized coils can also cause errors in the machine, while smaller, well-matched coils improve heating efficiency.

The material of the coil matters, too. Copper coils give you better conductivity and higher efficiency than aluminum or alloy coils. Adjustable coils let you work with different shapes and sizes of metal, making your induction forge more versatile.

Here is a table to help you match coil size and efficiency to your needs:

Tip: Adjustable and modular coils help you switch between different projects without changing the whole setup.

Cooling System

The cooling system keeps your induction heater running safely and efficiently. When you use your forge, the coil and power electronics get hot. If you do not cool them, the system can overheat and break down.

Most forges use either a radiator or a fan-based cooling system. Radiator systems use water or coolant to carry heat away from the coil. Fan systems blow air over the coil and electronics. Water-cooled systems are more common in larger or professional setups because they remove heat faster and keep the induction heating process stable.

You should check the cooling system for leaks, blockages, or worn-out parts. Regular maintenance helps prevent breakdowns and extends the life of your forge. Replacement parts for cooling systems are usually easy to find, especially for popular brands.

Water-cooled systems: Best for heavy-duty or long sessions.

Fan-cooled systems: Good for small or portable induction heater units.

Maintenance: Clean filters, check coolant levels, and replace worn hoses or fans.

Note: A well-maintained cooling system protects your investment and keeps your forge safe to use.

Frequency and Efficiency

Frequency is a key factor in how your induction heater works. The frequency controls how deep the heat goes into the metal. Most induction heating systems run between 10 and 50 kHz. Higher frequencies heat only the surface, while lower frequencies heat deeper into the metal.

If you work with small parts or thin stock, you need a higher frequency for fast, surface heating. For larger pieces or deep heating, a lower frequency works better. The right frequency also helps you avoid problems like hot spots or uneven heating.

Induction furnaces can run from 50 Hz up to 400 kHz or more. The choice depends on your material, the size of your forge, and how fast you want to heat. The skin depth effect means that higher frequencies only heat the outer layer, while lower frequencies reach deeper. For example, at 20 kHz, the heat may only go 0.2 to 5 mm deep, depending on the metal. If you use the wrong frequency, you might stall the heating at certain temperatures or create uneven results.

Remember: Matching the frequency to your project improves efficiency and helps you get the best results from your induction heating system.

Induction Heater Compatibility

You need to make sure your induction forge works well with your chosen induction heater. Compatibility depends on the design of the coil, the power supply, and the type of metal you want to heat. Many modern induction heaters use modular designs, so you can swap coils or adjust settings for different projects.

Technical tests and computer simulations help engineers match coils and power supplies. These tests check for things like impedance matching, which ensures the heater uses all its power efficiently. Some systems use magnetic flux concentrators to focus the heat exactly where you need it. Cooling water flow and velocity also play a role in keeping the coil working well.

You can find induction heaters that work with both ferrous and non-ferrous metals. True temperature control prevents overheating and sticking, which is important for forging and quenching. Case studies show that good compatibility reduces distortion and cracking during rapid heating.

Modular designs let you use one induction heater for many tasks.

Computer simulations help design coils that match your forge and materials.

Proper matching improves efficiency and extends the life of your equipment.

Portable induction heater models are available for small workshops or on-site jobs.

Tip: Always check the specifications and consult with experts if you are unsure about compatibility. This step saves time and money in the long run.

Practical Considerations

Cost and Budget

When you plan to add a new forge to your workshop, you should think about both the initial cost and the long-term savings. The first purchase price for an induction forge is usually higher than a traditional furnace. Over time, you can save money because induction systems use less energy and heat metal faster. You also waste less material since you can control the temperature more precisely. Maintenance costs are often lower because the forge has fewer moving parts that can break.

Operating costs are lower due to energy savings and less heat loss.

Faster heating means you finish projects quicker.

Less material waste saves you money.

Maintenance costs stay low because of fewer parts.

For small workshops, you can find DIY or rebranded 15kW induction forge units for about $759 to $1200. If you want a turnkey system with a water chiller, expect to pay around $2995. These options help you plan your budget, whether you want a simple setup or a complete solution.

Space and Power Supply

You need to check your workspace before you buy a forge. Some forges take up more room, especially if they have a large cooling system. Make sure you have enough space for the forge and for moving metal safely. Most induction forges heat one piece at a time, so plan your workflow around this.

Check your electrical supply, too. Some forges need special wiring or higher voltage. Always match the forge’s power needs to what your shop can provide.

Safety and Maintenance

Safety should always come first. Induction forges do not have open flames, so your workspace stays safer and cooler. Many models include safety features like automatic shut-off and temperature controls.

Maintenance is simple because the forge has fewer moving parts. You should check the cooling system, clean filters, and replace worn hoses or fans. Brands like Canroon make it easy to find replacement parts and support. Regular care keeps your forge running well and protects your investment.

Selection Checklist

Step-by-Step Guide

Choosing the right forge for your workshop can feel overwhelming. You can use this checklist to make the process easier and more reliable. Each step helps you focus on what matters most for your projects.

List Your Main Projects

Write down the types of metalwork you do most often. Include the size and shape of the workpieces.Check Power Needs

Match the power rating of the forge to your project size. Larger pieces need more power for even heating.Review Coil Options

Make sure the coil size and shape fit your typical stock. Adjustable coils give you more flexibility.Inspect Cooling Systems

Look for a cooling system that matches your usage. Water-cooled systems work best for long sessions.Evaluate Frequency Range

Choose a forge with a frequency that matches your material and heating depth needs.Test Compatibility

Confirm that your forge works with your chosen induction heater and materials.Monitor Performance

Use diagnostic tools like thermal imaging to check terminal connections. Watch for heater fault alarms and use plant load management systems to keep energy use efficient.Consider Material Properties

Think about the thermal properties and microstructure of your metals. Adjust coil design and power for the best results.

Tip: Regularly check your forge for loose connections or signs of wear. This keeps your system safe and efficient.

When to Consult Canroon

You should reach out to Canroon when you face any of these situations:

You have unique project requirements or need custom coil designs.

You notice frequent alarms or performance issues with your forge.

You want to upgrade your induction heater or need help with compatibility.

You need advice on plant load management or advanced process controls.

You want expert help to match your forge to new materials or applications.

Canroon’s team can guide you through technical questions and help you choose the best forge for your workshop. Their support ensures you get reliable performance and long-term value.

You can choose the right forge by following a few clear steps. Start by listing your blacksmith projects and blacksmithing needs. Check the power, coil, and cooling system for each forge. Use the checklist to compare options. A good forge helps you work faster and safer. Every blacksmith wants a forge that fits their blacksmithing style. If you need help, ask Canroon for advice. You will get the best forge for your workshop.

FAQ

What metals can you heat with an induction forge?

You can heat most ferrous metals like steel and iron. You can also heat some non-ferrous metals, such as copper and aluminum. Always check your forge’s compatibility with the metal you plan to use.

How safe is an induction forge compared to a gas forge?

Induction forges do not use open flames. Only the metal gets hot. This makes your workspace safer and cooler. Many models include automatic shut-off and temperature controls for extra safety.

Do you need special training to use an induction forge?

You do not need advanced training. Most users learn basic operation quickly. Always read the manual and follow safety instructions. Some projects may require extra practice or guidance.

How often should you maintain your induction forge?

You should check your forge before each use. Clean filters and inspect the cooling system every month. Replace worn parts as needed. Regular maintenance keeps your forge safe and efficient.

Please give us a message