News

Induction heating solutions utilize electromagnetic fields to heat materials without direct contact. This method ensures precise temperature control and uniform heating, enhancing the quality of industrial processes. With an Energy Saving Induction Heating Machine, you can benefit from significant energy savings, as induction transfers up to 84% of energy to the load. The Industrial Induction Heating Machine also boasts safety features, such as the absence of open flames, which help reduce workplace hazards.

Key Takeaways

Induction heating tools give exact heat control and even warming.

They can save up to 90% energy, cutting costs and waste.

Custom systems can be made for special needs, boosting work output.

Induction Heating Generators

Features of Advanced Generators

Induction heating generators are at the core of modern induction heating solutions. These advanced systems use electromagnetic fields to generate heat directly within the material, ensuring precise and efficient heating. Unlike traditional methods, they offer superior energy efficiency. For instance, a study by the Lawrence Berkeley National Laboratory revealed that induction heating transfers 84% of energy to the load, compared to 71% for electric coils and only 40% for gas burners. This efficiency reduces energy waste and operational costs.

A key feature of these generators is their ability to deliver consistent temperature distribution. This ensures uniform heating, which is critical for maintaining the quality of industrial processes. Additionally, advanced generators come equipped with digital controls, allowing you to set and monitor exact temperatures. This level of control minimizes errors and enhances productivity. Their compact design also makes them suitable for a wide range of applications, from small-scale operations to large industrial setups.

Benefits for Industrial Applications

Induction heating generators offer numerous benefits that make them indispensable in industrial settings. First, they provide efficient and targeted heating, reducing energy consumption and lowering electricity bills. Their ability to precisely control temperatures ensures uniform heating, which improves the quality of the final product. Faster heating times also increase throughput, allowing you to complete tasks more quickly.

These systems enhance operational performance by reducing thermal stresses on equipment, leading to greater reliability and durability. They also prioritize safety and environmental considerations. Induction heating eliminates open flames and reduces emissions, creating a safer and cleaner work environment. Furthermore, the efficiency of these systems minimizes waste, as they heat only the material and not the surrounding air.

By adopting an induction heating system, you can achieve significant energy savings and improve overall productivity. These generators are a cornerstone of modern industrial efficiency, offering unmatched precision, reliability, and cost-effectiveness.

Induction Heating Coils

Types and Configurations

Induction heating coils play a crucial role in the efficiency of the induction heating process. These coils, made from water-cooled copper tubing, generate an alternating electromagnetic field. This field induces current in the workpiece, creating heat due to I²R losses. The design and configuration of the coil determine the effectiveness of the heating process.

Different types of coils are available to suit various applications. Here’s a breakdown of common coil types and their uses:

Each coil type ensures precise temperature distribution, which is essential for achieving consistent results. For example, solenoid coils are ideal for cylindrical components, while pancake coils excel at heating flat surfaces. By selecting the right coil, you can optimize the reheating process and improve energy efficiency.

Applications in Heat Treatment

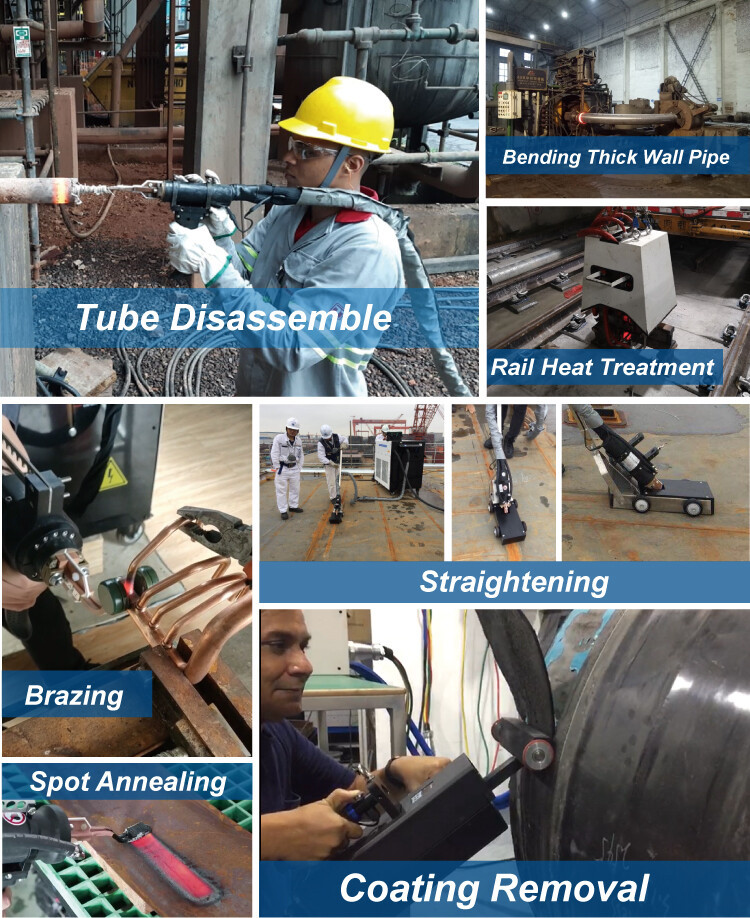

Induction heating coils are widely used in heat treatment processes due to their ability to deliver fast and controlled heating. These processes include metal hardening, annealing, forging, and brazing. Induction heating ensures uniform heating, enhancing material properties and productivity.

In the aerospace and automotive industries, induction heating is commonly used for hot heading and wire heating. It is also employed for surface and through-hardening applications, where rapid heating and controlled quenching provide precise results. For annealing, induction heating offers consistent softening of materials, making it ideal for aluminum alloy components. Additionally, brazing and soldering benefit from the rapid and controlled heating provided by induction, ensuring strong and reliable joints.

The reheating process with induction heating coils is not limited to industrial applications. Consumer appliances, such as induction cooktops, also utilize this technology for energy-efficient and rapid cooking. By leveraging induction heating, you can achieve superior results in both industrial and everyday applications.

Induction Brazing Systems

Precision in Metal Joining

Induction brazing systems offer unmatched precision in metal joining. Unlike traditional methods, such as torch or furnace brazing, induction brazing provides precise control over the heating process. This allows you to target specific areas, minimizing the risk of overheating or damaging sensitive components. The non-contact nature of induction brazing ensures consistent results, making it safer and more repeatable than open flame methods.

Several factors contribute to its precision:

Induction brazing heats only the joint interface, reducing the risk of part distortion.

The process minimizes metallurgical changes, preserving the integrity of the materials.

It generates heat directly within the workpiece, ensuring uniform temperature distribution.

Industries such as automotive, aerospace, and medical devices rely on induction brazing for its ability to create strong, reliable joints. For example, in the automotive sector, it is widely used to assemble vehicle components with high accuracy.

Efficiency and Control

Induction brazing systems excel in efficiency and control, making them a preferred choice for industrial applications. The process is faster than traditional methods, as it heats only the joint rather than the entire assembly. This results in shorter cycle times and increased productivity. Additionally, induction brazing consumes less energy by generating heat directly within the material, leading to significant cost savings.

The ability to control the reheating process precisely ensures consistent results. You can achieve targeted heating without wasting energy or overheating surrounding areas. This selective heating also reduces ambient air temperature, creating a safer and more comfortable work environment.

Industries benefit from these advantages in various ways:

Automotive manufacturers save time and energy during assembly.

Aerospace companies achieve high-quality joints for critical components.

Medical device makers ensure the durability and reliability of their products.

By adopting induction heating solutions like brazing systems, you can enhance efficiency, reduce costs, and maintain the quality of your operations.

Induction Hardening Machines

Surface Hardening for Durability

Induction hardening machines are essential for improving the durability of metal components. These machines use a power supply to generate high-frequency alternating current, which flows through an induction coil. The coil creates an alternating magnetic field that induces eddy currents in the workpiece. This localized heating process hardens specific areas of the material without altering its overall properties. A cooling system prevents overheating, ensuring precise control over the reheating process.

You can achieve consistent and repeatable results with advanced induction hardening equipment. Automated systems allow you to control heating and quenching parameters with precision. This reliability makes induction hardening suitable for mass production, where maintaining quality and performance standards is critical. Additionally, the process ensures uniform temperature distribution, which enhances the mechanical properties of the treated components. By tailoring induction coils to match the geometry of the part, you can optimize performance and extend the lifespan of the material.

Applications in Wear-Resistant Components

Induction hardening plays a vital role in creating wear-resistant components across various industries. The process strengthens parts to withstand high stresses, extreme conditions, and repeated use. Here’s how different sectors benefit from this technology:

By using induction heating for hardening, you can improve the durability of critical components. This process ensures that parts like gears, axles, and tools perform reliably under demanding conditions. Whether you work in manufacturing, construction, or energy, induction hardening offers a cost-effective solution for enhancing wear resistance and extending the life of your equipment.

Induction Melting Furnaces

High-Temperature Efficiency

Induction melting furnaces are highly efficient tools for achieving extreme temperatures in industrial processes. Unlike traditional furnaces, they use direct heating methods, which minimize energy loss and improve thermal efficiency. This approach ensures that the heat is concentrated directly within the metal, reducing waste and speeding up the melting process. You can melt large volumes of metal quickly, which enhances productivity in high-demand environments.

These furnaces also provide precise temperature control. This feature allows you to regulate the melting process, preserving the alloying elements in metals and ensuring consistent quality. The uniform temperature distribution achieved by induction heating prevents overheating or uneven melting, which is critical for maintaining the integrity of the material. By adopting this technology, you can save energy, reduce costs, and achieve superior results in your operations.

Applications in Metal Casting

Induction melting furnaces are widely used in metal casting industries due to their flexibility and efficiency. They support a variety of applications, including:

Melting precious metals like gold and silver.

Copper and aluminum melting for manufacturing.

Alloy production for specialized components.

These furnaces are also essential for creating high-quality castings in automotive parts, turbine blades, and machine components. Their ability to deliver precise and controlled heating ensures cost-effectiveness and sustainability. Whether you work in jewelry production or heavy machinery, induction melting furnaces provide reliable solutions for your casting needs.

Induction Annealing Systems

Metal Softening and Flexibility

Induction annealing systems provide an efficient way to soften metals and enhance their flexibility. This process uses an electromagnetic field to heat metals to specific temperatures, reducing hardness and improving ductility. By surrounding the metal with an induction coil, alternating current generates heat directly within the material. The metal is then heated to its annealing temperature and held there for a precise duration. This controlled heating ensures consistent and repeatable results, which are essential for industrial applications.

You can rely on induction annealing to improve the workability of metals. The process minimizes the risk of overheating and distortion, preserving the material's structural integrity. Whether you need to prepare metals for further machining or improve their ability to withstand stress, induction annealing offers a reliable solution. Its precision and efficiency make it a preferred choice for industries requiring high-quality results.

Benefits for Industrial Processes

Induction annealing systems offer several advantages that enhance industrial processes. Localized heating allows you to target specific areas without affecting surrounding regions, reducing thermal stress. The efficient energy transfer minimizes heat loss, optimizing energy utilization and lowering operating costs. Precise temperature control ensures materials reach the desired state without errors, improving the quality of the final product.

These systems also increase productivity by reducing cycle times through rapid heating and cooling. Their flexibility allows you to tailor the process for various materials, making them suitable for diverse manufacturing needs. Additionally, induction heating improves the electrical and structural properties of metals, enhancing their performance in critical applications. By adopting induction annealing, you can achieve energy efficiency, cost savings, and superior results.

Induction Shrink Fitting Solutions

Precision Assembly Techniques

Induction shrink fitting solutions provide a reliable method for assembling metal components with precision. This technique involves heating one part to expand it, allowing another part to fit securely. Once cooled, the components form a tight and durable bond. You can rely on this method for applications requiring high structural integrity and accuracy.

Process repeatability, accuracy, energy efficiency, and speed are four hallmarks of induction heating for virtually any application. Additionally, induction heating delivers heat to the targeted part, not the atmosphere around it, so there is no risk of distortion.

Industries such as automotive and heavy machinery benefit significantly from this technology. For example:

Automotive manufacturers use it to shrink-fit gears and rings.

Offshore platforms and turbines rely on it for assembling heavy-duty components.

This method ensures consistency and controllability, making it ideal for high-precision assembly processes. By adopting induction shrink fitting, you can achieve excellent mechanical properties and long-lasting results.

Time and Cost Efficiency

Induction shrink fitting solutions save time and reduce costs in industrial applications. The process heats components quickly, cutting heating times from 40 minutes to just 2 minutes. This speed increases productivity and shortens production cycles.

The energy efficiency of induction heating also lowers operational costs. By delivering heat directly to the material, it minimizes energy waste and reduces the risk of overheating or material damage. Consistent results further decrease defects, saving you money on consumables and repairs.

With induction shrink fitting, you can streamline your operations while maintaining high-quality standards. This technology offers a faster, more cost-effective alternative to traditional methods, ensuring both efficiency and reliability.

Induction Welding Systems

Seamless and Rapid Metal Joining

Induction welding systems provide a fast and reliable solution for joining metals. This method uses electromagnetic fields to generate heat directly within the material, ensuring precise and consistent welds. You can achieve seamless results, even in high-volume production environments, thanks to the rapid heating capabilities of induction welding. This speed significantly reduces cycle times, allowing you to enhance productivity without compromising quality.

The versatility of induction welding makes it suitable for various applications, from automotive manufacturing to pipeline construction. By delivering uniform heat across large batches, it ensures consistent weld quality. You can also minimize waste and rework since the precise control of heating parameters reduces errors. Additionally, localized heating minimizes thermal stress and distortion, eliminating the need for extensive preheating or post-weld heat treatment. This efficiency saves both time and resources, making induction welding an ideal choice for industrial applications.

Energy Efficiency in Welding

Induction welding systems excel in energy efficiency, offering significant advantages over traditional methods. By heating the material directly, they minimize energy loss and reduce overall consumption. This direct heating approach ensures that more energy is converted into usable heat, lowering operational costs. For instance, induction heaters can convert up to 90% of the energy into heat, compared to the lower efficiency of gas or electric resistance heaters.

You can also benefit from the rapid heat generation of induction heating, which further enhances process efficiency. This technology not only reduces electricity bills but also supports sustainable practices by minimizing wasted energy. Whether you’re working on small-scale projects or large industrial operations, induction welding provides a cost-effective and environmentally friendly solution.

Portable Induction Heating Units

Flexibility for On-Site Repairs

Portable induction heating units offer unmatched flexibility for on-site repairs, making them indispensable in industrial and maintenance settings. These compact systems allow you to perform localized heating tasks with precision and efficiency. Unlike traditional methods, they eliminate the need for open flames or direct contact, ensuring safer operations in diverse environments.

Here’s a breakdown of the key features that make these units ideal for on-site applications:

These features make portable induction heating units a reliable choice for industries like automotive, aerospace, and construction. Whether you need to loosen a rusted bolt or prepare a surface for welding, these units deliver consistent results with minimal effort.

Applications in Maintenance

Portable induction heating units excel in a wide range of maintenance tasks, thanks to their versatility and efficiency. Here are some of the most common applications:

Removing rusted or seized parts.

Shrink fitting by expanding metal for assembly.

Bending and shaping metal components.

Hardening or annealing metal for durability.

Soldering and brazing for precise metal joining.

Preheating materials for welding.

Tightening and loosening fasteners like bolts and nuts.

Shrink fitting bearings or bushings.

In-line heating for assembly processes.

Heat treatment of components for enhanced performance.

Stress relieving after welding to improve material properties.

These applications demonstrate the adaptability of portable induction heating units. By using this technology, you can streamline maintenance tasks, reduce downtime, and improve overall efficiency. Whether you’re working in a workshop or on-site, these units provide a practical and cost-effective solution for your heating needs.

Custom Induction Heating Solutions

Tailored Systems for Unique Needs

Custom induction heating solutions are designed to meet the specific needs of your industry. These systems are not one-size-fits-all; they are developed through a detailed assessment of your operational requirements. By tailoring the design, you can achieve greater efficiency and precision in your processes.

Engineers collaborate with you to create induction heating coil designs that align with your unique applications, such as heat treatment, forging, or automotive manufacturing.

The design process emphasizes precision in coil configuration. This ensures uniform temperature distribution and reduces energy consumption, which are critical for efficient heating.

Custom systems enhance operational efficiency by addressing the exact specifications of your materials, whether it’s steel, copper, or even aluminum alloy components.

Tip: A well-designed induction heating system can significantly improve productivity while lowering energy costs. By investing in a tailored solution, you ensure that your equipment performs optimally for your specific industrial needs.

Addressing Specific Industrial Challenges

Custom induction heating systems excel at solving complex industrial challenges. These systems adapt to unique scenarios, providing reliable and efficient solutions for demanding applications.

Thermal Expansion: Induction systems help expand large components for removal, a common need in power generation and steel mills.

Rusted Nuts and Bolts: Induction coils break the bond of rusted fasteners, making disassembly faster and easier.

Boiler Tube Removal: Worn-out boiler tubes can be heated and removed without damaging the surrounding structure.

High-Temperature Testing: Induction heating achieves temperatures up to 4000°F, enabling advanced material testing.

Rapid Coating Curing: Custom machines speed up the curing process for coatings, reducing production line length and increasing throughput.

These examples highlight how induction heating can address specific challenges across industries. Whether you need to remove degraded components or perform high-speed curing, custom solutions provide the flexibility and precision required for success.

The top 10 induction heating solutions demonstrate how advanced technology can revolutionize industrial processes. These solutions offer benefits like rapid heating, precise temperature control, and improved energy efficiency. By adopting induction heating, you can enhance productivity, reduce costs, and maintain consistent quality. Selecting the right system ensures long-term benefits tailored to your specific needs.

Investing in induction heating solutions not only boosts operational efficiency but also supports sustainability. With reduced energy consumption and safer processes, these technologies pave the way for a cleaner and more productive future.

ure precise heating, energy savings, and improved productivity for unique industrial applications.

Tip: Consult with experts to design a system that fits your exact operational needs.

Please give us a message