News

Heat induction machines deliver efficient heating solutions for industrial processes. These machines use advanced technology to provide precision and reliability. The Canroon CR2000 series stands out with innovative features, offering robust performance. Industries benefit from their environmentally friendly operation and ability to meet modern production demands.

Key Takeaways

Heat induction machines use less energy, saving up to 30%. This helps lower costs compared to gas burners.

These machines control temperature accurately. This improves product quality and prevents bending or warping during work.

The Canroon CR2000 series heats quickly and needs little upkeep. It is a dependable option for many industries.

Key Features of Heat Induction Machines

Energy Efficiency and Cost Savings

Heat induction machines are designed to optimize energy consumption, making them highly efficient for industrial applications. Their advanced power devices reduce energy loss by minimizing on-state resistance and voltage drop. This improvement translates to lower operational costs and enhanced performance. Additionally, the integration of resonant technology ensures that the power supply operates at a load power factor of 1, further reducing energy waste.

Tip: Industries can achieve up to a 30% reduction in energy consumption by switching from traditional gas burners to heat induction machines.

A study comparing induction heating to conventional methods highlights its energy transfer efficiency of 84%, which is significantly higher than the 40% efficiency of gas burners. This efficiency not only saves costs but also contributes to sustainable practices by reducing carbon emissions.

Precision Heating for Industrial Applications

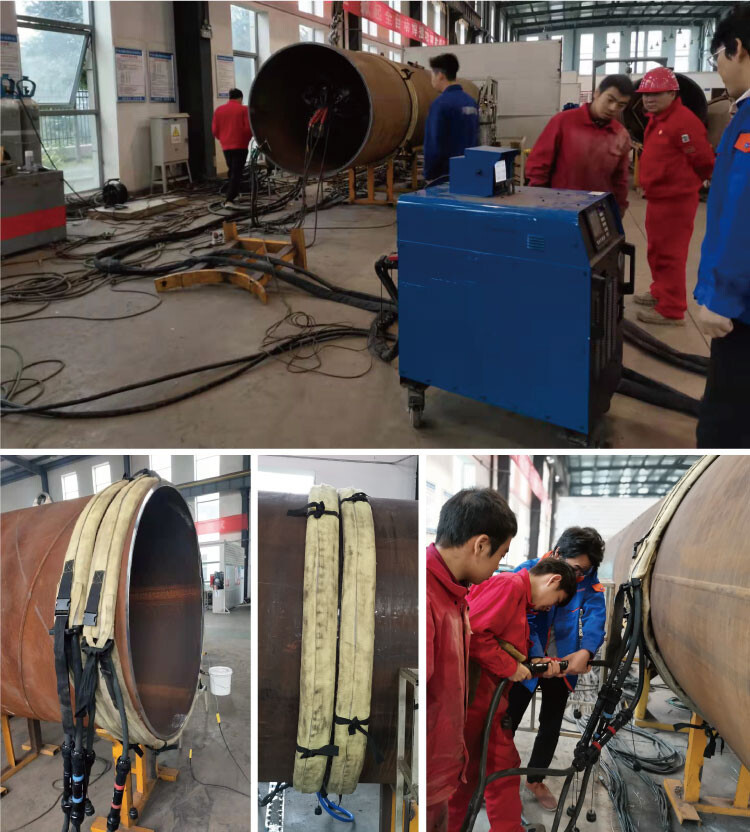

Heat induction machines excel in delivering precise heating solutions, which are critical for maintaining production quality. Their ability to control temperature uniformly ensures minimal distortion during processes like welding preheat and post-weld heat treatment. This precision is particularly beneficial for applications involving steel pipes in oil and gas pipeline construction.

Key Benefits of Precision Heating:

Uniform temperature control enhances the integrity of welds and coatings.

Reduced distortion improves the quality of the finished product.

Faster production speeds increase operational efficiency by 20%.

Induction heating systems, such as the Canroon CR2000 series, utilize intelligent power modules with built-in diagnostics. These modules ensure consistent performance and reliability, making them indispensable for demanding industrial applications.

Fast and Controlled Heating Processes

Heat induction machines offer rapid heating capabilities, enabling faster production cycles. Unlike gas-fired ovens, which require long heat-up and cool-down times, induction heating delivers immediate results. This speed is complemented by precise control, allowing operators to target specific areas without affecting the entire workpiece.

The Canroon CR2000 series stands out with its wide output frequency range of 3-35kHz, which allows for fine-tuned control over heating processes. This feature is particularly useful for applications requiring high accuracy, such as post-weld heat treatment.

Safety and Environmental Benefits

Heat induction machines prioritize safety and environmental performance. Their compact and modular design ensures easy integration into existing production lines while minimizing electromagnetic exposure risks. Compliance with EN-12198 standards guarantees worker safety during operation.

The environmentally friendly operation of heat induction machines further enhances their appeal. By eliminating the need for fossil fuels, these machines reduce greenhouse gas emissions, aligning with global sustainability goals.

Technical Specifications of Heat Induction Machines

Power Output and Frequency Range

Heat induction machines are designed to deliver high power output and operate across a wide frequency range. These specifications ensure adaptability for various industrial applications. The machines typically feature input voltages compatible with standard power systems and maintain a high power factor for efficient energy use.

The Canroon CR2000 series heat induction machine offers a wide output frequency range of 3-35kHz, enabling precise control over heating processes. This flexibility makes it suitable for applications requiring high accuracy, such as welding preheat and post-weld heat treatment.

Cooling Systems and Temperature Control

Efficient cooling systems play a vital role in maintaining the performance and longevity of heat induction machines. Modern systems integrate air and water cooling mechanisms to manage heat effectively. A study comparing air-cooled and integrated water-cooled systems demonstrated significant temperature reductions with water flow rates of 5 LPM, 10 LPM, and 15 LPM, achieving reductions of 2.94%, 4.79%, and 7.69%, respectively.

The Canroon CR2000 series incorporates advanced cooling technology to ensure stable operation even under demanding conditions. Its robust design minimizes overheating risks, enhancing reliability and operational efficiency.

Note: Proper cooling not only extends the machine's lifespan but also ensures consistent performance during prolonged use.

Material Compatibility and Coil Design

Material compatibility and coil design are critical for the efficiency and effectiveness of heat induction machines. These factors determine the machine's ability to handle various materials and achieve uniform heating. Tests on insulation resistance and partial discharge (PD) have shown that mica paper provides excellent mechanical and electrical properties, making it an ideal choice for slot insulation.

The Canroon CR2000 series features a C-type inductor, which enhances heating efficiency and ensures precise temperature control. This design is particularly effective for applications involving steel pipes, where uniform heating is essential for maintaining structural integrity.

Advanced Features in Canroon's CR2000 Heat Induction Machines

The Canroon CR2000 series stands out with its advanced features, designed to meet the demands of modern industrial applications. Key features include:

Wide Power Range: Operates between 40 to 160KVA, accommodating diverse operational needs.

Precise Temperature Control: Ensures consistent heating, crucial for welding preheat and post-weld heat treatment.

Durable Construction: Built with high-quality aluminum, offering resistance to harsh industrial environments.

Versatile Frequency Range: Supports an output frequency of 3-35kHz, allowing fine-tuned control over heating processes.

These features make the CR2000 series a reliable and efficient choice for industries such as construction, energy, and mining. Its robust design and advanced technology ensure optimal performance, even in challenging conditions.

Applications and Benefits of Heat Induction Machines

Industrial Applications Across Sectors

Heat induction machines serve diverse industries by providing efficient and precise heating solutions. Their versatility makes them suitable for applications ranging from food processing to aerospace. A study highlights their sector-specific benefits:

These applications demonstrate the adaptability of heat induction machines across sectors, enhancing operational efficiency and safety.

Benefits in Manufacturing and Production

Heat induction machines improve manufacturing processes by delivering consistent and controlled heating. Their ability to target specific areas reduces waste and ensures high-quality results. Industries benefit from faster production cycles, lower energy consumption, and reduced maintenance costs.

For example, in plastic processing, these machines enhance precision and safety by generating heat electrically. In aerospace, they increase efficiency during composite material bonding and annealing. These advantages make heat induction machines indispensable for modern manufacturing.

Advantages of Canroon CR2000 Heat Induction Machines Over Traditional Methods

The Canroon CR2000 series offers significant advantages over traditional heating methods. Its precise temperature control ensures uniform heating, which is critical for maintaining the integrity of welds and coatings. The machine’s wide output frequency range allows fine-tuned control, making it ideal for demanding applications like post-weld heat treatment.

Unlike gas burners, the CR2000 series operates efficiently without long heat-up times. Its durable aluminum construction withstands harsh industrial environments, ensuring reliability and longevity. These features position the CR2000 series as a superior choice for industries seeking advanced heating solutions.

Maintenance and Considerations

Regular Maintenance for Optimal Performance

Proper maintenance ensures the longevity and efficiency of heat induction machines. Routine checks and advanced diagnostic tools help identify potential issues before they escalate. Techniques such as vibration analysis detect mechanical problems by monitoring vibration patterns, while infrared thermography identifies overheating or insulation failures. Lubrication schedules reduce friction and wear, ensuring smooth operation.

Predictive maintenance strategies, supported by condition monitoring systems, minimize downtime and repair costs. These practices ensure optimal performance and extend the machine's lifespan.

Factors to Consider When Selecting a Heat Induction Machine

Selecting the right heat induction machine requires evaluating thermal efficiency, operational needs, and cost-effectiveness. Machines with higher thermal efficiency, such as prototypes K-2 and K-3, achieve efficiencies of 77.14% and 87.1%, respectively. Increasing air mass flow rates and applying insulation further enhance efficiency, improving performance by up to 13%.

Design considerations, including material compatibility and frequency range, also play a crucial role. Machines like the Canroon CR2000 series, with a wide frequency range and precise temperature control, offer versatility for various industrial applications. Cost analysis should include energy savings and reduced maintenance expenses, ensuring long-term value.

Ensuring Longevity with Canroon CR2000 Heat Induction Machines

The Canroon CR2000 series incorporates advanced features to ensure durability and reliability. Its robust aluminum construction withstands harsh industrial environments, while its efficient cooling system prevents overheating. Regular maintenance, including winding insulation checks and lubrication, enhances its performance.

The machine’s precise temperature control and wide frequency range reduce wear and tear, ensuring consistent operation. By following recommended maintenance practices, industries can maximize the lifespan of the CR2000 series, making it a cost-effective and reliable choice for demanding applications.

Heat induction machines, like the Canroon CR2000 series, deliver unmatched precision and efficiency for industrial heating. Their advanced features and versatile applications make them a smart investment for businesses. Understanding their capabilities and maintenance needs helps industries optimize performance, reduce costs, and achieve long-term operational success.

FAQ

What industries benefit the most from heat induction machines?

Heat induction machines serve industries like construction, energy, aerospace, and manufacturing. Their precision and efficiency make them ideal for welding, coating, and heat treatment applications.

How does the Canroon CR2000 ensure precise temperature control?

The CR2000 uses a C-type inductor and advanced technology to deliver uniform heating. This ensures consistent results for welding preheat and post-weld heat treatment.

Are heat induction machines environmentally friendly?

Yes, they eliminate fossil fuel usage, reducing greenhouse gas emissions. Their energy-efficient operation aligns with global sustainability goals, making them an eco-friendly choice.

Please give us a message