News

Induction heating equipment is set to transform industries in 2025. It enhances speed and accuracy in factories. The global market for magnetic induction heaters, a key component of induction heating equipment, is valued at $586.98 million and is growing at a rate of 4.3% annually. Canroon is at the forefront with its advanced induction heating equipment, emphasizing quality and eco-friendliness.

Key Takeaways

Induction heating tools work faster and more precisely in factories.

New materials like silicon carbide and gallium nitride save energy.

IoT and AI help these machines track and fix problems quickly.

Improvements in Power Electronics for Induction Heating Machines

High-frequency inverters for precise heating

High-frequency induction heating has changed how heating tasks are done. These inverters work at higher frequencies for better precision. They heat only the needed area, saving energy and boosting efficiency. Whether for small parts or big industrial items, these machines offer great control. Their steady performance makes them popular in car and airplane industries.

Silicon carbide (SiC) and gallium nitride (GaN) for better results

New materials like silicon carbide (SiC) and gallium nitride (GaN) have improved these machines. These materials provide:

Lower resistance, improving how they work.

Higher power density for smaller designs.

Strong heat handling, making machines more effective.

Using SiC and GaN helps machines perform better while saving energy. These upgrades make sure your equipment works well, even in tough situations.

Smaller and smarter designs for today’s needs

Modern industries need smaller, smarter heating machines. Smaller designs save energy, cut costs, and lower pollution. Induction machines turn electricity into heat efficiently, making them eco-friendly.

These smaller machines save space and support global green goals. By using them, you help the planet and improve your work processes.

Integration of Industry 4.0 in Induction Heating Technology

IoT-enabled systems for smarter operations

Industry 4.0 has changed how induction heating works. IoT systems let machines share data easily. They give real-time updates on performance and energy use. You can check and control heating processes from anywhere. This improves accuracy and reduces machine downtime. For instance, in car wire production, IoT cut energy use by 30%. It also made wires stronger.

AI-driven optimization for improved efficiency

AI makes induction heating smarter and more efficient. It uses data from IoT devices to adjust settings automatically. This keeps quality steady and saves energy. AI also predicts equipment needs, avoiding sudden breakdowns. Using AI lowers costs and boosts productivity.

Real-time analytics for predictive maintenance

Real-time analytics improve how you care for machines. Predictive maintenance checks equipment health using IIoT data. It spots problems early, so you can fix them quickly. Machine learning studies data over time to make predictions better.

Real-time data helps you decide faster.

MES systems with data tools give deeper insights.

Extra details make sensor data more useful.

Using these tools keeps your induction heating systems running well and saves energy.

Energy Efficiency and Sustainability in Induction Heating Equipment

Air-cooled systems for reduced energy use

Air-cooled systems are changing how induction heating works. They use air instead of water for cooling, saving energy. These systems are simpler and need less maintenance. They keep machines cool without losing performance. This makes them great for industries wanting to save energy.

Studies show air-cooled systems cut energy use effectively. For example, combined air and water systems lower temperatures by 7.69%. But air-cooled systems are easier to use and support green goals. Switching to air-cooled systems can save money and help the environment.

Using renewable energy sources

Renewable energy is now part of induction heating systems. High-frequency heating is already eco-friendly by using electromagnetic induction. It heats materials directly, cutting fossil fuel use and CO2 emissions. Now, industries pair it with solar or biomass energy for better results.

Solar heating works well in sunny areas for green manufacturing. Almost half of industrial energy needs can be electrified today. Adding renewable energy to your system boosts efficiency and lowers your carbon footprint.

Eco-friendly materials and methods

Eco-friendly materials are changing how heating equipment is made. High-frequency heating is precise and saves energy, making it greener. Manufacturers now use renewable energy and sustainable materials to meet demand.

Switching from fossil fuels to clean energy cuts emissions a lot. Using green materials helps industries meet environmental goals. This keeps processes efficient while being eco-friendly. These changes show a strong focus on saving energy and protecting the planet.

Customization and Flexibility in Induction Heating Machines

Modular designs for different industrial needs

Modular designs help machines fit many industries. You can change parts to meet specific needs without buying a new machine. This saves money and makes upgrades easier. These systems also let you grow your business smoothly, whether you handle small items or big parts.

Tip: Modular designs work well for industries like cars and planes, where accuracy and flexibility matter.

Companies can add their own labels and branding. Customizing machines improves their market appeal. It also helps meet customer needs better. Efficient production, especially in China, keeps these options affordable.

Special solutions for unique tasks

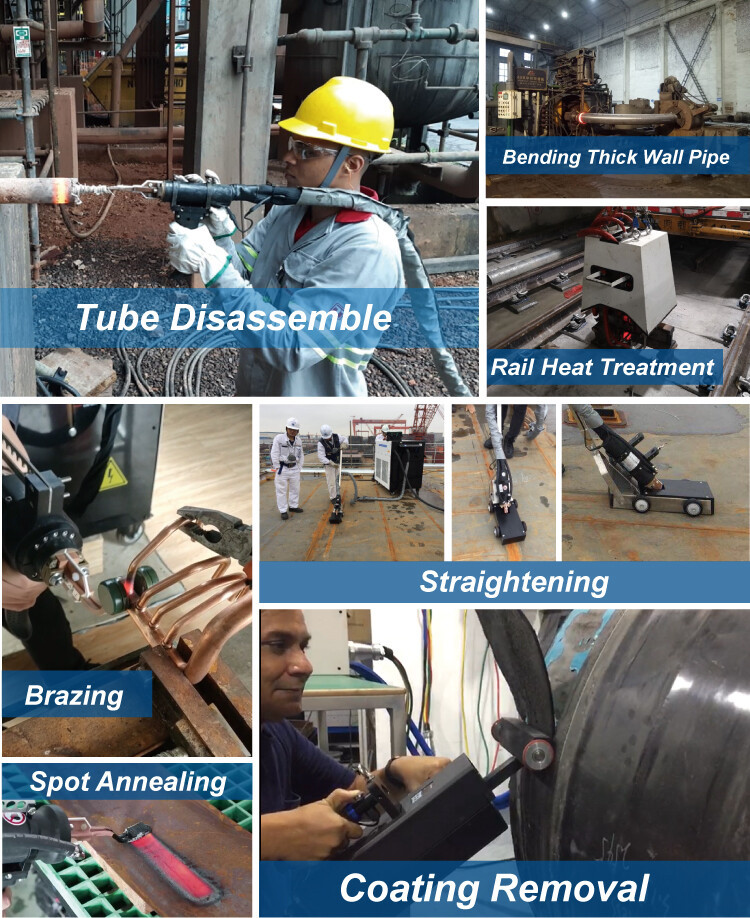

Induction heating machines solve tough industrial problems. High frequency heating gives exact control, making it great for tasks like hardening, brazing, and annealing. You can tweak settings to get the right results for each material or job.

Why special solutions are helpful:

Better product quality with accurate heating.

Higher efficiency by focusing on specific tasks.

Lower energy use by heating only what’s needed.

Customizing machines lets industries try new ideas and improve their processes.

Growth options for businesses of all sizes

Scalability means these machines grow with your business. Small shops or big factories can use them. Start simple and add more as your business expands.

High frequency induction heating is key for growth. Its small size and energy savings work for both small and large setups. This flexibility helps industries stay productive and eco-friendly.

Enhanced Process Automation in Induction Heating Technology

Automated temperature control for precision

Automated systems make induction heating more accurate. They use sensors to check heat levels, with only a 5 °C error. These sensors work in a range of 60 to 250 °C. Real-time adjustments keep the temperature steady during use. This is very important for industries like cars and planes. Even small temperature changes can affect product quality.

These systems give consistent heating, save energy, and cut waste. They also make hard tasks easier by adjusting heat automatically. This lets you focus on other work while the machine runs smoothly.

Integration with robotics for seamless workflows

Robots change how induction heating machines work. They help with tasks like moving and placing materials. This teamwork reduces mistakes and speeds up production. For example, robotic arms can place parts perfectly for heating. This ensures even results every time.

Using robots with these machines makes work faster and more efficient. It also saves energy and improves accuracy. These upgrades make your processes smarter and more dependable.

Streamlined processes for higher productivity

Automation makes work simpler and faster. Induction heating machines with smart features reduce delays and improve accuracy. They handle tough jobs with little help from people.

Main benefits include:

Better energy savings

Smoother operations

More precise heating

These features help you finish work quickly without losing quality. Automation keeps your work flowing and helps you stay ahead in busy industries.

Induction Heating Equipment in Additive Manufacturing

Uses in 3D printing and material processing

Induction heating machines are changing 3D printing and material work. These machines heat materials precisely, making strong, high-quality parts. A new method, hybrid heat-source solid-state additive manufacturing (HHSAM), shows great results. It improves materials like 5A06 aluminum alloy. This method makes materials stronger, harder, and more durable. It also boosts corrosion resistance, making them last longer in tough jobs.

To get the best results with induction heating in 3D printing, follow these tips:

These settings help you make better products and meet modern needs.

Helping advanced manufacturing methods

Induction heating helps advanced manufacturing by improving speed and accuracy. Special computer tools design better coil shapes for even heating. New power supplies make parts harder and work faster. Better cooling systems for coils stop overheating and keep machines working well.

These upgrades make your work faster, more reliable, and ready for detailed designs.

Canroon’s impact on additive manufacturing

Canroon is a leader in using induction heating for manufacturing. They create tools that are precise and eco-friendly. Their technology helps you make great parts while saving energy. Canroon supports industries like aerospace and cars to use advanced methods.

With Canroon, you get machines that work well and help your business grow. Their focus on innovation keeps you ahead in a fast-changing world.

Induction heating is changing industries with exciting new improvements. Key updates include better electronics, smarter systems, and energy-saving designs. The market is expected to grow from $10.33 billion in 2024 to $17.61 billion by 2034 because of its powerful impact.

Industries like cars, planes, and factories are seeing big advantages.

Canroon leads this change with smart and green solutions. Their focus helps you stay ahead in today’s fast-moving industries.

FAQ

What industries gain the most from induction heating equipment?

Industries like cars, planes, and factories benefit greatly. It makes work faster, saves energy, and heats materials accurately for better products.

How does induction heating help the environment?

Induction heating uses less energy and eco-friendly materials. It lowers pollution by using renewable energy and cutting waste during heating.

Can induction heating machines be adjusted for special tasks?

Yes, you can change parts to fit specific jobs. This makes them useful for many industries and helps businesses grow.

Tip: Talk to companies like Canroon for the best machine options for your needs.

Please give us a message