News

Interference problems in water pump VFDs often arise from electrical disturbances, such as reflected wave voltage. This occurs due to the rapid switching of IGBTs in the VFD Variable Frequency Drive. Long cable lengths amplify these effects, leading to over-voltage conditions that stress insulation and damage motors or cables, impacting system performance and reliability.

Key Takeaways

Look for signs of VFD problems like uneven pressure or shaky signals. Finding issues early stops damage and keeps the system working well.

Use correct grounding methods to lower electrical interference. One strong, low-resistance ground reduces problems and makes VFDs work better.

Install shielded twisted-pair wires to stop high-frequency noise. This easy fix keeps your equipment safe and your water pump running smoothly.

Identifying Symptoms of VFD Disturbances

Irregular pressure transmitter behavior

You might notice unusual behavior in your pressure transmitter when dealing with VFD disturbances. For instance, the transmitter may fail to provide consistent readings. This happens because the interference problem disrupts the signal transmission between the VFD and the pressure transmitter. As a result, the system struggles to maintain accurate pressure levels. If left unchecked, this issue can lead to inefficient water pump operation and potential damage to the equipment.

Unstable or fluctuating signals

Unstable signals are another common sign of VFD disturbances. You may observe that the output signals from your VFD fluctuate unexpectedly. These fluctuations often occur due to electromagnetic interference or harmonic distortion within the system. When this happens, the water pump may operate erratically, causing inconsistent flow rates or pressure levels. Identifying this symptom early can help you address the disturbance before it escalates into a more significant problem.

Random signal jumps or noise

Random signal jumps or excessive noise in the system indicate a disturbance caused by the VFD. This symptom often results from poor grounding or unshielded cables. You might hear unusual sounds or see erratic changes in the system's performance. These issues not only affect the efficiency of your water pump but also increase the risk of long-term damage. Paying attention to these signs can help you pinpoint the source of the interference problem and take corrective action.

Causes of Harmonic Interference in VFDs

Harmonic disturbances in the power supply

Harmonic interference in the power supply can significantly affect the performance of your VFD. These disturbances occur when non-linear loads, such as VFDs, draw current in abrupt pulses rather than smooth waves. This disrupts the normal sinusoidal waveform of the power supply, creating harmonic currents that interfere with the operation of other equipment. You might notice reduced efficiency or overheating in your water pump system as a result.

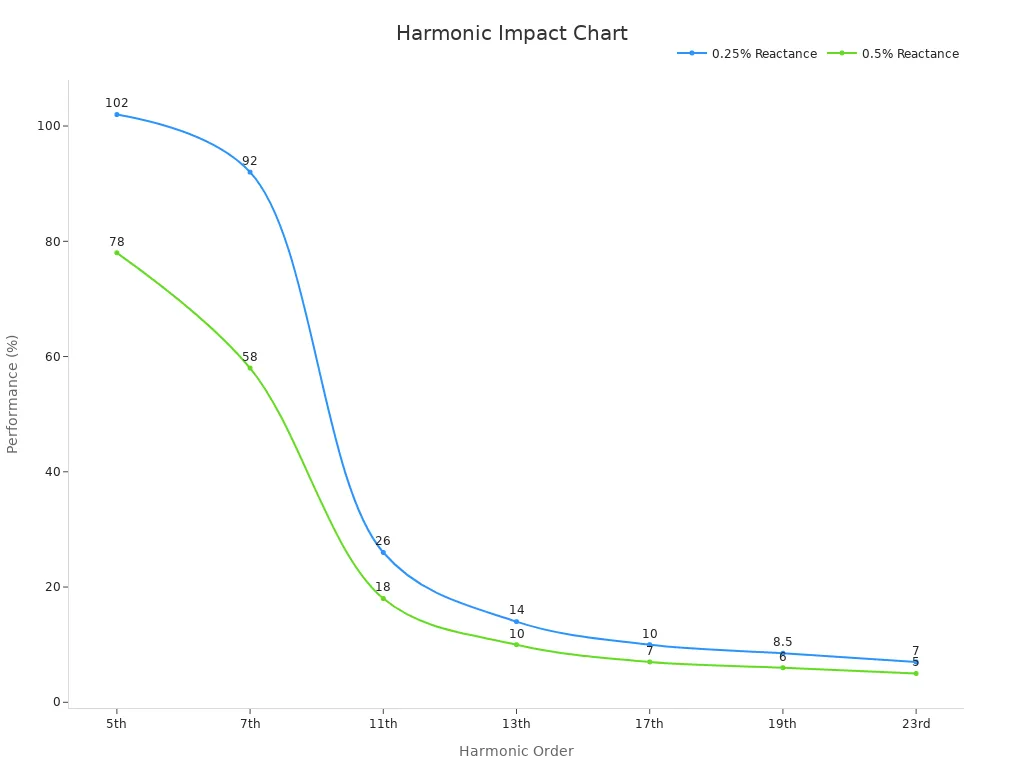

To illustrate the impact of harmonic disturbances, consider the following data on harmonic orders and their effects on VFD performance:

This table shows how higher harmonic orders contribute to total harmonic current distortion (THID). Lowering reactance levels can help reduce these effects, improving the reliability of your VFD system.

By addressing harmonic disturbances early, you can prevent long-term damage to your equipment and maintain stable operations.

Radiated emissions from high-frequency lines

High-frequency lines in your VFD system can emit radiated electromagnetic interference. This occurs when the rapid switching of power transistors generates high-frequency signals that radiate into the surrounding environment. These emissions can disrupt nearby electronic devices, including pressure transmitters and control systems.

You can minimize this type of interference by using shielded cables and ensuring proper grounding. Shielded cables block radiated emissions, while grounding provides a safe path for stray currents. These measures help maintain the integrity of your VFD system and reduce the risk of electromagnetic interference affecting other equipment.

Electromagnetic radiation from unshielded cables

Unshielded cables are a common source of electromagnetic radiation in VFD systems. When cables lack proper shielding, they allow high-frequency noise currents to escape, creating electromagnetic disturbances. These disturbances can interfere with other devices on the same network, leading to erratic behavior or signal loss.

Research findings highlight several mechanisms through which unshielded cables cause interference:

To combat these issues, you should replace unshielded cables with shielded ones and connect them to the housing of the VFD and motor. This reduces electromagnetic disturbances and ensures smoother operation of your water pump system.

Solutions to Address the Interference Problem

Proper grounding techniques

Proper grounding plays a critical role in resolving interference problems in water pump VFD systems. It ensures that unwanted noise from the frequency inverter dissipates safely, reducing the risk of radio frequency conducted emission interference. You should connect all grounding points to a single, low-impedance ground to prevent ground loops. This approach minimizes disturbances caused by stray currents.

Tip: Reliable grounding enhances the effectiveness of shielding layers, providing better protection against radio frequency radiation interference.

To implement grounding for enhanced shielding, ensure that the motor, VFD, and control panels share a common ground. This setup prevents electromagnetic disturbances from spreading across the system. By prioritizing proper grounding, you can achieve stable VFD performance and extend the lifespan of your equipment.

Using shielded twisted-pair cables

Shielded twisted-pair cables are an effective solution for mitigating electromagnetic interference in VFD installations. These cables reduce radio frequency radiation interference by blocking high-frequency noise. Their design also provides a low impedance return path, which minimizes stray currents and enhances system reliability.

When selecting shielded cables, ensure they are properly terminated and connected to the housing of the motor and VFD. This connection improves effective shielding measures, reducing the risk of interference problems. By using shielded cables, you can maintain consistent system performance and protect your equipment from damage.

Installing EMC filters and line reactors

EMC filters and line reactors are essential for addressing interference problems in VFD systems. These components reduce radio frequency conducted emission interference and lower harmonic currents, ensuring smoother operation. EMC filters block high-frequency noise on power lines, while line reactors limit harmonic distortion.

Installing these filters ensures that your VFD system complies with electromagnetic compatibility standards. You can also prevent equipment malfunctions and improve overall system reliability. For optimal results, place the filters close to the VFD and motor to maximize their effectiveness.

Isolating power supplies and reducing pulse frequency

Isolating power supplies is another effective way to address interference problems. By separating the power supply of the VFD from other sensitive equipment, you can minimize the impact of radio frequency conducted emission interference. Use isolation transformers to achieve this separation and protect your system from disturbances.

Reducing the pulse frequency of the VFD also helps lower harmonic currents and radio frequency radiation interference. Lowering the switching frequency reduces the amount of high-frequency noise generated by the VFD. This adjustment improves the stability of your water pump system and reduces the risk of interference affecting nearby devices.

Placing VFDs in shielded enclosures

Shielded enclosures provide an additional layer of protection against radio frequency radiation interference. These enclosures block electromagnetic emissions from the VFD, preventing them from affecting other equipment. You should select enclosures made of conductive materials, such as aluminum or steel, to ensure effective shielding measures.

When installing a VFD in a shielded enclosure, ensure that all cables entering or exiting the enclosure are properly shielded and grounded. This setup enhances grounding for enhanced shielding and minimizes the risk of interference problems. By using shielded enclosures, you can maintain a stable and interference-free environment for your water pump system.

You can effectively manage any interference problem in your water pump system by identifying symptoms, understanding causes, and applying practical solutions. Focus on proper grounding, shielding, and preventive maintenance. These steps ensure your vfd operates smoothly. Addressing issues early enhances efficiency and extends the lifespan of your vfd system.

FAQ

What is the most common cause of interference in VFD systems?

Electromagnetic interference (EMI) from unshielded cables or improper grounding often causes disturbances. These issues disrupt signals and reduce the efficiency of your water pump system.

How can you identify harmonic interference in your VFD?

Look for symptoms like fluctuating signals, erratic motor behavior, or overheating. These signs often indicate harmonic distortion affecting your VFD's performance.

Do shielded cables completely eliminate interference?

Shielded cables significantly reduce interference but may not eliminate it entirely. Combine them with proper grounding and EMC filters for optimal results.

Tip: Regularly inspect your cables and connections to maintain effective shielding and grounding.

Please give us a message