News

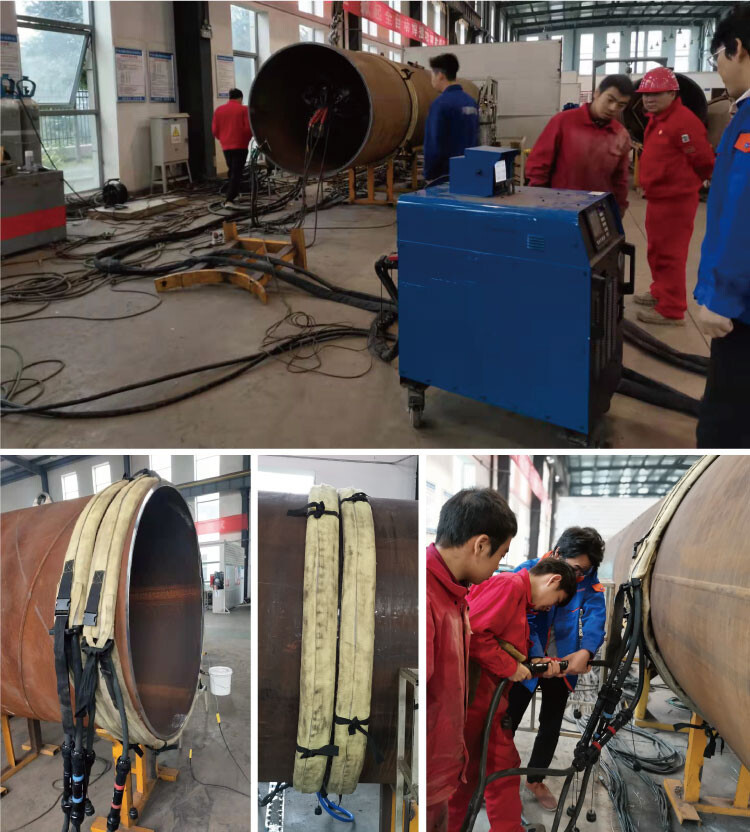

Precision and efficiency are essential to staying competitive in today’s industries. Canroon's PWHT machine transforms industrial processes with advanced technology. The Post Weld Heat Treatment Machine ensures your structures withstand stress and deliver reliable performance. Whether it’s the 80KW Pipe Induction Heater Machine or the PWHT Induction Heating Machine, Canroon provides unparalleled solutions for enhancing structural durability.

Key Takeaways

PWHT makes welded parts stronger and more reliable by reducing leftover stresses and boosting toughness.

Canroon's PWHT machines control heat accurately, giving better weld quality and results.

Using Canroon's PWHT machines saves money and energy, helping businesses be more eco-friendly.

Understanding PWHT and Its Industrial Importance

Defining PWHT and Its Role in Welding

Post weld heat treatments (PWHT) play a vital role in modern welding processes. PWHT involves controlled heating and cooling of welded components to improve their structural properties. This process reduces welding residual stress, which can compromise the integrity of joints. By refining the grain structure, PWHT enhances toughness, ductility, and hardness, ensuring the durability of welded materials. Whether you work in aerospace, automotive, or construction, PWHT ensures your welds meet the highest standards of safety and performance.

Addressing Welding Challenges with PWHT

Welding introduces challenges like residual stress, distortion, and the risk of cracks. PWHT addresses these issues effectively. For instance, it provides stress relief by alleviating welding residual stress, minimizing the chances of stress corrosion cracking. Technological advancements in PWHT have also improved its precision. Research shows that careful temperature management during PWHT prevents the formation of brittle carbides, maintaining the toughness of materials. This makes PWHT indispensable for industries requiring high-strength components, such as pressure vessels and pipelines.

Why PWHT is Crucial for Modern Industries

Industries rely on PWHT to ensure the safety and longevity of their products. It is essential for applications involving high pressure, extreme temperatures, or corrosive environments. For example, PWHT enhances corrosion resistance in pipelines and pressure vessels, ensuring they withstand harsh conditions. It also prevents brittle fractures in critical components, such as aircraft parts and vehicle frames. Moreover, PWHT ensures compliance with stringent industry standards, making it a cornerstone of quality assurance in modern manufacturing.

Unique Features of Canroon's PWHT Machines

Precision in Temperature Control

Canroon's PWHT machines excel in delivering precise temperature control, ensuring your welding processes achieve optimal results. The advanced digital temperature control system allows you to maintain exact heating levels, reducing the risk of overheating or underheating. Multiple thermocouples monitor the temperature across different points, providing accurate measurements and consistent results.

Here’s how Canroon ensures precision:

This level of control enhances the quality of your welds, making them more durable and reliable. Whether you're working on pipelines, pressure vessels, or structural components, you can trust Canroon's machines to deliver unmatched accuracy.

Energy Efficiency and Environmental Benefits

Canroon's PWHT machines are designed with energy efficiency in mind. By using advanced induction heating technology, these machines consume less power while delivering high performance. This not only reduces your operational costs but also minimizes your carbon footprint. You contribute to a greener planet while maintaining top-notch industrial standards. Choosing Canroon means you’re investing in both efficiency and sustainability.

Adherence to International Standards

When you use Canroon's PWHT machines, you meet the highest industry standards. These machines comply with international safety and quality regulations, ensuring your projects pass rigorous inspections. This adherence boosts your credibility and guarantees the safety of your operations. With Canroon, you align with global benchmarks, giving you a competitive edge in the market.

Applications of PWHT Machines Across Industries

Power Generation: Boilers and Turbines

In the power generation sector, the reliability of boilers and turbines is critical. You need components that can withstand extreme temperatures and pressures. PWHT machines ensure the durability of these components by reducing residual stresses and improving their metallurgical properties. This process enhances the performance of welded joints, making them resistant to cracking and deformation. By using a PWHT machine, you can extend the service life of boilers and turbines, ensuring uninterrupted power supply and reducing maintenance costs.

Construction: Buildings and Bridges

The construction industry relies on PWHT to improve the structural integrity of buildings and bridges. Welded joints in steel structures often face fatigue and stress over time. PWHT addresses these challenges by refining the grain structure and enhancing the fatigue strength of welded components. Recent studies highlight the effectiveness of local PWHT in reducing residual stress in stiffened steel plates used in bridges. This method not only improves the durability of structures but also offers a cost-effective alternative to traditional furnace treatments. By incorporating PWHT into your construction projects, you ensure safer and longer-lasting infrastructure.

Aerospace: Aircraft Components

The aerospace industry demands precision and reliability. Aircraft components must endure high stress and extreme conditions. PWHT plays a vital role in ensuring the safety and performance of these components. By relieving residual stresses and enhancing the toughness of welded joints, PWHT ensures that aircraft parts meet stringent safety standards. Whether it’s the welding of pressure vessels or structural components, PWHT guarantees the highest level of quality. With Canroon's advanced PWHT machines, you can achieve the precision required in aerospace applications.

Automotive: Vehicle Frames and Parts

In the automotive industry, safety and durability are paramount. PWHT enhances the mechanical properties of vehicle frames and parts, ensuring they can withstand impact and stress. It improves the microstructure of high-strength steel, preventing brittle fractures and enhancing ductility. Additionally, PWHT mitigates hydrogen-induced cracking, which can compromise weld integrity. By using PWHT machines, you can produce safer and more reliable vehicles, meeting the demands of modern automotive manufacturing.

PWHT enhances the strength, toughness, and ductility of weldments.

It prevents brittle fractures, ensuring vehicle safety.

Hydrogen-induced cracking is mitigated, improving weld integrity.

Petrochemical: Pipelines and Pressure Vessels

The petrochemical industry operates in harsh environments where pipelines and pressure vessels face extreme conditions. PWHT is essential for maintaining the integrity of these components. It reduces the sensitivity and severity of cracking in welds, especially in high-strength steels. By enhancing the corrosion resistance of materials, PWHT ensures that pipelines and pressure vessels can withstand corrosive environments. This process not only improves safety but also extends the lifespan of critical infrastructure.

PWHT preserves the integrity of pressure vessels in cracking-prone environments.

It diminishes the severity of weld cracking in high-strength steels.

Shipbuilding: Structural Components

Shipbuilding requires robust and durable structural components. PWHT ensures that welded joints in ships can withstand the stresses of marine environments. By relieving residual stresses and improving the toughness of welds, PWHT enhances the safety and performance of ships. Whether you’re constructing cargo vessels or naval ships, PWHT machines provide the reliability you need for long-term operation.

Mining: Heavy Machinery

Mining equipment operates under extreme conditions, making durability a top priority. PWHT improves the structural integrity of heavy machinery by reducing residual stresses and enhancing the toughness of welded joints. This process ensures that mining equipment can handle heavy loads and resist wear and tear. By using PWHT machines, you can increase the lifespan of your machinery and reduce downtime, improving overall productivity.

Nuclear Power: Pressure Vessels and Piping

In the nuclear power industry, safety is non-negotiable. Pressure vessels and piping must meet the highest standards of quality and reliability. PWHT ensures that these components can withstand high temperatures and pressures without failure. By refining the grain structure and relieving residual stresses, PWHT enhances the performance and safety of nuclear power systems. Canroon’s PWHT machines help you achieve compliance with stringent industry standards, ensuring the safe operation of nuclear facilities.

Railway and Bridges: Welded Joints

Railway tracks and bridges rely on strong welded joints to ensure safety and durability. PWHT improves the fatigue strength of these joints, making them resistant to stress and wear. Studies show that local PWHT is an economical and effective method for reducing residual stresses in bridge structures. By incorporating PWHT into your railway and bridge projects, you can enhance the longevity and reliability of these critical infrastructures.

Benefits of Using Canroon's PWHT Machines

Enhanced Structural Integrity

When it comes to welded components, structural integrity is non-negotiable. Canroon's PWHT machines ensure your welds achieve unmatched durability and reliability. By applying precise post heating, these machines relieve residual stresses that can weaken welded joints. This process enhances the toughness and ductility of materials, making them resistant to cracking and deformation. Whether you're working on pipelines, pressure vessels, or structural components, you can trust Canroon's technology to deliver superior results.

The advanced temperature control system in Canroon's PWHT machines ensures uniform heating across the entire weld. This eliminates weak points and ensures consistent performance under extreme conditions. For industries requiring high-strength components, such as aerospace or nuclear power, this level of precision is critical. With Canroon, you can confidently meet the demands of modern industrial applications.

Tip: Investing in Canroon's PWHT machines not only improves the quality of your welds but also reduces the risk of costly repairs or failures down the line.

Energy Efficiency and Cost Savings

Canroon's PWHT machines are designed to save you time, energy, and money. By utilizing advanced induction heating technology, these machines consume significantly less power compared to traditional methods. This not only lowers your operational costs but also reduces your environmental impact. The innovative post heating process ensures optimal energy utilization, making your operations more sustainable.

Here’s a breakdown of the cost-saving benefits you can expect:

By choosing Canroon's PWHT machines, you gain a competitive edge. You’ll not only cut costs but also contribute to a greener planet. This makes Canroon the ideal choice for industries aiming to balance profitability with sustainability.

Compliance with Safety and Quality Standards

Meeting safety and quality standards is essential for any industrial operation. Canroon's PWHT machines help you achieve compliance with the most rigorous international codes and regulations. These machines are designed to meet the requirements of standards such as the ASME Boiler and Pressure Vessel Code, the Pressure Equipment Directive (PED), and API standards. This ensures your projects pass inspections and meet legal requirements.

Key compliance benefits include:

Pressure vessels comply with national and international codes, ensuring safety and legality.

Adherence to the latest revisions of applicable standards guarantees up-to-date practices.

Collaboration with third-party inspection agencies ensures thorough quality checks.

By using Canroon's PWHT machines, you demonstrate your commitment to safety and quality. This not only boosts your credibility but also minimizes the risk of operational failures. With Canroon, you can confidently deliver projects that meet the highest industry standards.

Note: Staying compliant with safety and quality standards is not just a legal requirement—it’s a commitment to excellence that sets you apart from competitors.

Post Weld Heat Treatment (PWHT) is vital for modern industries. It ensures your components resist stress, corrosion, and brittleness, delivering long-term reliability. Canroon's PWHT machines stand out with precise temperature control, energy efficiency, and compliance with global standards.

Investing in Canroon means safer, stronger, and more durable industrial solutions.

FAQ

What industries benefit the most from Canroon's PWHT machines?

Industries like aerospace, automotive, construction, and nuclear power gain the most. You’ll ensure safety, durability, and compliance with stringent standards in these demanding fields. ????

How does Canroon's PWHT machine save energy?

Canroon’s advanced induction heating technology optimizes energy use. You’ll reduce power consumption, lower costs, and contribute to a greener planet. ????

Are Canroon's PWHT machines easy to operate?

Yes! Canroon designs its machines with user-friendly controls. You’ll experience seamless operation, even if you’re new to PWHT processes. ????

Please give us a message