News

Have you ever wondered how heating can be both fast and energy-efficient? Canroon's induction heating systems make this possible by using electromagnetic induction to generate heat directly within materials. This method eliminates unnecessary heat loss, saving up to 50% more energy compared to traditional heating methods. With rapid industrialisation in regions like Asia-Pacific, the adoption of these Energy Saving Induction Heating solutions is skyrocketing. In fact, the global market for induction heating systems is projected to grow from £10.33 billion in 2024 to £17.61 billion by 2034. These systems, including the Industrial Induction Heating Machine, are not just about efficiency—they’re about precision, safety, and a cleaner future. The Fast Heating Induction Heating Equipment is leading the way in this transformation, ensuring that industries can meet their heating needs swiftly and sustainably.

Key Takeaways

Canroon's induction heating systems use 50% less energy than old methods. This makes them a cheaper option for industries.

These systems heat things very quickly, starting in under 0.2 seconds. This helps make production faster and more efficient.

Induction heating is cleaner, with very little pollution. It supports eco-friendly goals, helping both nature and your business.

Understanding Induction Heating

The Science of Induction Heating

Induction heating is a fascinating process that uses electromagnetic induction to generate heat directly within a material. When you place a conductive object in a time-varying magnetic field, it creates eddy currents inside the material. These currents produce heat due to electrical resistance, a phenomenon known as Joule heating. If the material is ferromagnetic, magnetic hysteresis adds to the heat generation as the magnetic dipoles align and realign with the changing field. This method is incredibly efficient because the heat is generated within the material itself, eliminating energy loss.

Faraday's Law and the Skin Effect

Faraday's Law of Induction is the backbone of induction heating. It explains how a changing magnetic field induces an electromotive force (EMF) in a conductive material. This EMF generates the eddy currents responsible for heating. The skin effect plays a crucial role here. It causes the eddy currents to concentrate near the surface of the material, making the heating process more efficient. For smaller parts, high-frequency induction creates a shallow skin effect, while lower frequencies are better for larger components. The material's properties, like resistivity and permeability, also influence the depth and efficiency of heating.

Key Advantages of Induction Heating

Induction heating offers several benefits that make it a game-changer for industries. It’s incredibly energy-efficient, saving costs while reducing environmental impact. The process is fast, allowing you to heat materials in seconds. Precise temperature control ensures consistent quality, which is vital for applications like metal hardening or melting. Plus, it’s a clean method, producing minimal emissions compared to traditional heating systems.

How Canroon's Induction Heating Systems Work

Components of the System

Canroon's induction heating systems are made up of several key components that work together seamlessly to deliver efficient and precise heating. Here’s a quick breakdown of these components and their roles:

Each part plays a vital role in ensuring the system operates smoothly. For example, the induction power supply provides the energy needed to create the electromagnetic field, while the cooling system keeps the equipment running efficiently by managing heat levels. Together, these components make the induction heating process both reliable and effective.

Proprietary Technologies

Canroon takes induction heating to the next level with its proprietary technologies. These innovations enhance performance and adaptability, making their systems stand out. Here are some highlights:

The CR1000 Series achieves an electricity-to-heat transformation rate of over 95%.

It offers a service life exceeding 50,000 hours, perfect for demanding industrial applications.

Multiple heating modes allow you to tailor the system to specific needs.

With a rapid start time of less than 0.2 seconds, you can begin heating almost instantly.

Advanced overload protection ensures safety, with 120% protection for one minute and instant protection at 150%.

The system operates effectively at altitudes below 1000 metres, with power adjustments for higher altitudes.

It withstands relative humidity below 90% without condensation, ensuring durability in various environments.

These features make Canroon's induction heating systems a reliable choice for industries requiring high performance and adaptability.

Applications of Induction Heating in Industry

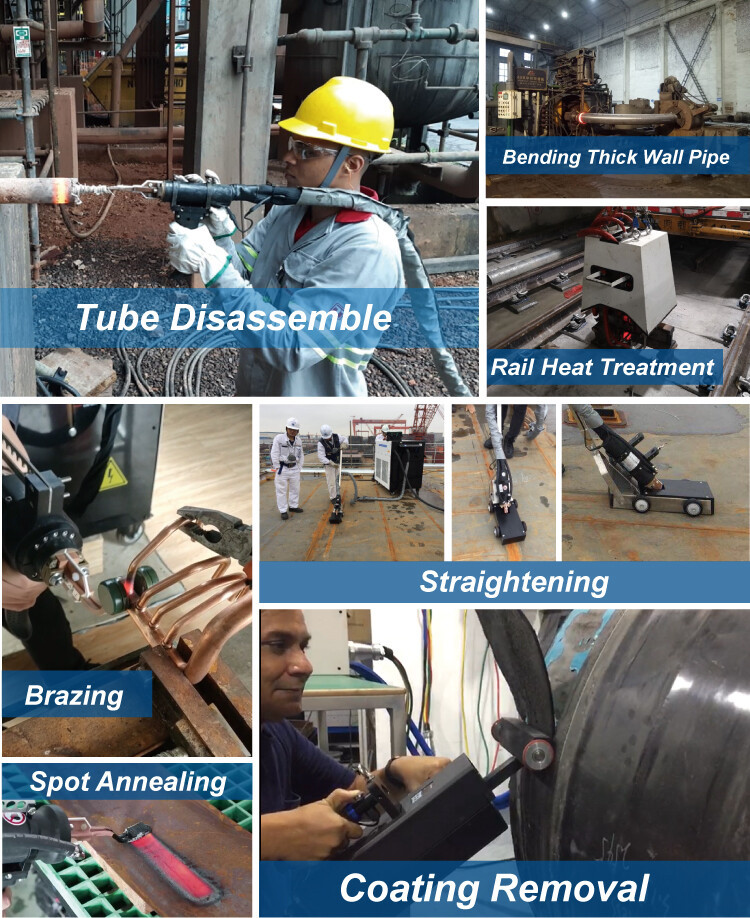

The versatility of Canroon's induction heating systems makes them suitable for a wide range of industrial applications. Here’s a look at where these systems shine:

From metalworking to food processing, the applications of induction heating are vast. Whether you’re looking to harden metal parts or sterilise equipment, Canroon’s systems provide the precision and efficiency you need.

Benefits of Canroon's Induction Heating Systems

Energy Efficiency and Cost Savings

Canroon's induction heating systems are designed to save you both time and money. Their rapid heating capabilities streamline industrial processes, reducing energy consumption and operational costs. Unlike traditional methods, which often waste energy, these systems heat materials directly and efficiently. For instance, the CR1000 Series achieves an impressive electricity-to-heat transformation rate of over 95%. This means you can optimise production cycles while cutting down on energy bills.

What’s more, the quick start time of less than 0.2 seconds ensures minimal energy wastage. You’ll also benefit from a cleaner heating process with fewer emissions, aligning with sustainability goals. By choosing induction heating, you’re not just saving costs—you’re investing in a smarter, greener future.

Precision and Safety

Safety and precision are at the heart of Canroon's induction systems. These machines offer complete protection features, including under-voltage, over-current, and water shortage safeguards. Core components are protected from overheating, ensuring durability and reliability. The system also provides overload protection for up to one minute at 120% and instant protection at 150%.

With precise temperature control, you can achieve consistent results every time. Whether you’re hardening metal parts or curing composites, the accuracy of induction heating ensures high-quality outcomes. Plus, the flame-free operation eliminates the risks associated with open flames, making your workplace safer.

Environmental Impact

Induction heating is a cleaner, more sustainable alternative to traditional methods. By using electromagnetic fields to generate heat, these systems eliminate the need for combustion. This results in minimal emissions and a non-polluting process. Canroon's systems align perfectly with modern sustainability goals, helping you reduce your carbon footprint.

Here’s a quick look at the measurable benefits:

By adopting Canroon's induction heating systems, you’re not just improving efficiency—you’re actively contributing to a healthier planet.

Induction Heating vs Traditional Heating Methods

Efficiency and Speed

When it comes to efficiency and speed, induction heating systems leave traditional methods far behind. Induction systems heat materials directly, which means there’s minimal energy waste. This direct approach also allows for rapid heating, saving you valuable time in production. For example, Canroon’s systems can start heating in less than 0.2 seconds, ensuring you don’t waste time waiting for equipment to warm up.

Traditional heating methods, on the other hand, often rely on indirect heat transfer, which takes longer and consumes more energy. They also lack the precise temperature control that induction systems offer. With induction, you can achieve consistent results, reducing waste and improving product quality. Whether you’re working with metals or composites, the speed and precision of induction heating make it a superior choice.

Maintenance and Durability

Induction heating systems are built to last. Canroon’s CR1000 Series, for instance, boasts a service life of over 50,000 hours. This durability means fewer replacements and lower maintenance costs for you. Advanced features like overload protection also enhance reliability, allowing the system to perform efficiently in various environments.

In contrast, traditional heating equipment often requires frequent maintenance due to wear and tear. Components like burners or heating elements degrade over time, leading to higher operational costs. By switching to induction heating, you can enjoy a more reliable and cost-effective solution.

Environmental Considerations

Induction heating is a cleaner, greener alternative to traditional methods. It uses electromagnetic fields to generate heat, eliminating the need for combustion. This flame-free process significantly reduces emissions, aligning with modern sustainability goals.

Here’s a quick comparison:

By choosing induction heating, you’re not just improving efficiency—you’re also contributing to a healthier planet. It’s a win-win for your business and the environment.

Canroon's induction heating systems are transforming industrial heating with their unmatched efficiency and versatility. These systems deliver precision heating for metalworking and other demanding applications.

Designed with sustainability in mind, they eliminate open flames, reduce emissions, and align with modern environmental goals.

Explore Canroon's innovative solutions and experience the future of heating technology today!

FAQ

What is a work piece in induction heating?

A work piece is the material you heat using induction. It could be metal, plastic, or other conductive materials, depending on your industrial application.

How does induction heating affect the work piece?

Induction heating generates heat directly within the work piece. This ensures precise, efficient heating without wasting energy or damaging surrounding materials.

Can Canroon's systems handle different types of work pieces?

Yes, Canroon's systems are versatile. They adapt to various work piece sizes, shapes, and materials, making them ideal for diverse industrial applications.

Please give us a message