News

Induction heating operates by producing eddy currents within electrically conductive materials. Metals, including ferrous metals, non-ferrous metals, and precious metals, can be effectively heated by induction. The efficiency of this process depends on factors such as electrical resistance, material thickness, and the distance from the inductor. For instance:

Ferrous metals are easily heated by induction due to their magnetic properties.

Non-ferrous metals depend on their conductivity for heating.

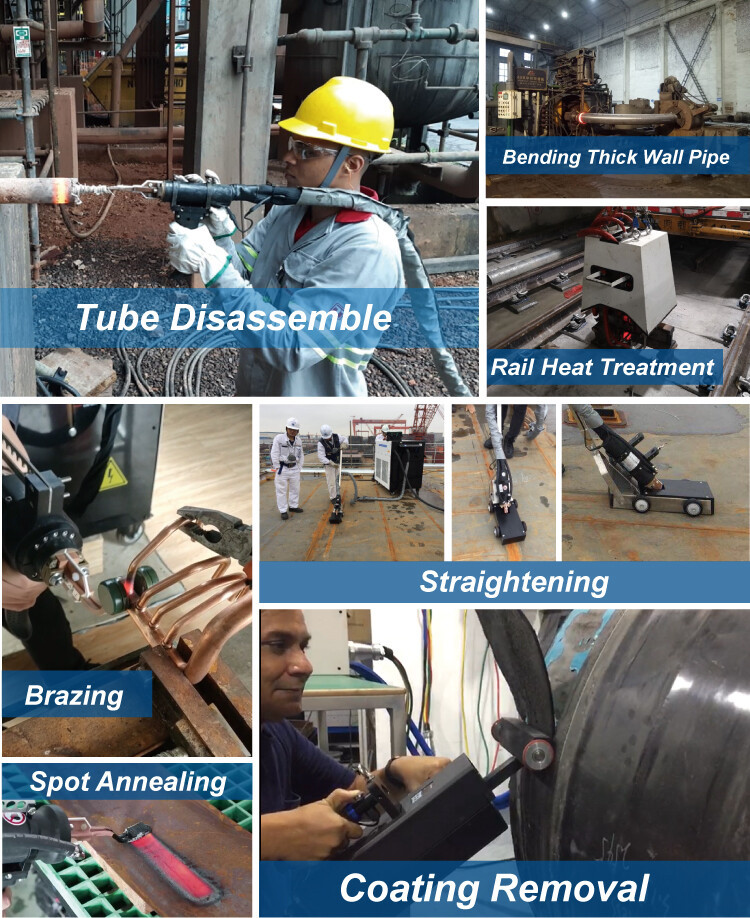

Canroon's Induction Heating Machine For Metal is perfectly suited for processes like Metal Brazing Annealing, offering precise and efficient heating solutions.

Key Takeaways

Induction heating warms metals like iron, copper, and gold quickly.

Metals like steel heat better because they are magnetic. Non-magnetic metals heat due to their ability to conduct electricity.

Induction heating uses up to 50% less energy than old methods. This makes it a cheaper option for factories.

How Induction Heating Works

Electromagnetic induction and eddy currents

Induction heating relies on the scientific principle of electromagnetic induction to generate heat in conductive materials. When you expose a metal to an alternating electromagnetic field, electric currents, known as eddy currents, are induced within the material. These currents flow through the metal's resistance, producing heat through a process called Joule heating.

Faraday's Law of Induction explains this phenomenon. It states that a changing magnetic field creates an electromotive force (EMF) in a conductive material. This EMF drives the eddy currents, which are responsible for heating the metal. For example, when you place a metal part inside an induction coil, the alternating magnetic field induces these currents, causing the metal to heat up. This method is widely used in industrial applications like soldering, annealing, and tempering because it delivers precise and localized heating.

Eddy currents play a crucial role in this process. They flow through the material's resistance, generating heat efficiently. The intensity of the magnetic field and the material's conductivity determine how much heat is produced. Even non-magnetic metals can be heated effectively using this method, thanks to the action of eddy currents.

Factors influencing heating efficiency

Several factors affect the efficiency of induction heating. The material's electrical conductivity is one of the most important. Metals with high conductivity, like copper and aluminum, heat up quickly because they allow eddy currents to flow easily. Magnetic properties also play a role. Ferrous metals, such as steel, heat more efficiently due to their ability to concentrate the magnetic field.

The thickness of the material influences how deeply the heat penetrates. Thicker materials require more energy to heat evenly. The distance between the metal and the induction coil also matters. Keeping the material close to the coil ensures better energy transfer and minimizes heat loss.

Induction heating is highly efficient compared to traditional methods. It transfers heat directly to the metal, avoiding unnecessary energy loss to the surrounding environment. Unlike conventional ovens, it doesn’t require pre-heating, saving both time and energy. This precision reduces waste and enhances productivity, making it a preferred choice for many industries.

Types of Metals Heated by Induction

Ferrous metals and their magnetic properties

Ferrous metals, such as iron and steel, are ideal for induction heating due to their magnetic properties. These metals generate heat efficiently through eddy currents and the hysteresis effect. You’ll find ferrous metals like alloy steel, carbon steel, cast iron, and wrought iron in applications requiring strength and durability. For example:

Alloy steel and carbon steel are used in construction projects like skyscrapers and bridges.

Cast iron is common in automotive manufacturing and tools.

The magnetic nature of ferrous metals enhances their heating efficiency. Induction heating systems concentrate energy in these materials, making them suitable for melting, refining, and other industrial processes.

Non-ferrous metals and conductivity

Non-ferrous metals, including copper, aluminum, and brass, are also heated by induction. These metals lack magnetic properties but excel in electrical conductivity. Copper and aluminum, for instance, heat efficiently through eddy currents. You’ll often see these metals in electrical wiring, cookware, and automotive components.

Although induction heating is less efficient for non-ferrous metals, specialized equipment can improve the process. This ensures effective heating for applications requiring precision and speed.

Precious metals and their applications

Precious metals like gold, silver, and platinum are highly conductive, making them suitable for induction heating. This method ensures precise temperature control, which is essential for maintaining purity during smelting. For example, gold and silver are widely used in jewelry and electronics. Induction furnaces also play a key role in recycling these metals from electronic waste, promoting sustainability.

Platinum group metals, such as palladium and platinum, are vital in medical equipment and catalytic converters. Induction heating provides the controlled environment needed for these high-value applications.

Refractory metals and high-temperature uses

Refractory metals, including tungsten and molybdenum, are known for their high melting points, exceeding 3,632°F (2,000°C). These metals retain their strength under extreme heat, making them ideal for demanding applications like aerospace and industrial furnaces.

Their resistance to thermal shock ensures durability during rapid temperature changes. Induction heating offers the precision required to process these metals effectively, even in high-temperature environments.

Magnetic vs. Non-Magnetic Metals

Heating efficiency of magnetic metals

Magnetic metals, such as iron and steel, excel in induction heating due to their unique properties. These materials generate heat through both eddy currents and the hysteresis effect. The hysteresis effect occurs when the magnetic domains within the metal resist changes in the magnetic field, producing additional heat. This dual mechanism makes magnetic metals more efficient to heat compared to non-magnetic ones.

For industrial applications, induction heating offers precise temperature control for magnetic metals. Processes like induction melting and casting benefit from this efficiency. For example, steel can be melted with minimal energy loss, ensuring consistent material properties and reducing contamination risks.

Mechanisms for heating non-magnetic metals

Non-magnetic metals, such as copper and aluminum, rely solely on eddy currents for heating. These metals lack the hysteresis effect, which makes their heating less efficient. However, their high electrical conductivity allows eddy currents to flow effectively, enabling induction heating to remain a viable option.

Non-magnetic metals like aluminum and copper generate heat only through eddy currents, unlike magnetic metals that also benefit from the hysteresis effect. This results in lower heating efficiency for non-magnetic metals. To address these challenges, adjustments can be made in the induction heating setup, such as increasing the wattage, changing the frequency of operation, or modifying the design of the induction coil.

You can enhance the heating efficiency of non-magnetic metals by:

Increasing the power input to the induction system.

Adjusting the frequency to match the material's properties.

Modifying the thickness or alloy composition of the metal.

Technological advancements have further improved the heating of non-magnetic metals. Modern induction systems achieve efficiency values exceeding 90%, ensuring rapid heating with minimal energy loss. This precision makes induction heating ideal for processes like bonding, hardening, and softening non-ferrous metals.

Induction heating is a highly versatile method for heating metals like iron, copper, and gold. It offers energy efficiency, precise temperature control, and enhanced safety. You can achieve up to 50% energy savings compared to traditional methods. This technology adapts to diverse industrial needs, from metalworking to electronics, ensuring consistent quality and reduced waste.

Key Benefits of Induction Heating:

Energy efficiency minimizes costs and environmental impact.

Precise heating ensures uniform results.

Safer operations with no exposed flames or heating elements.

Induction heating continues to revolutionize industries by providing rapid, localized heating for ferrous and non-ferrous metals. Its adaptability makes it an essential tool for modern manufacturing.

FAQ

What types of metals are best suited for induction heating?

Ferrous metals like steel and iron work best due to their magnetic properties. Non-ferrous and precious metals also heat effectively with proper adjustments.

Can you heat non-magnetic metals with induction?

Yes, you can. Non-magnetic metals like copper and aluminum heat through eddy currents. Adjusting power and frequency improves efficiency.

Is induction heating energy-efficient?

Absolutely! Induction heating minimizes energy loss by directly heating the metal. You can save up to 50% energy compared to traditional methods.

Please give us a message