News

An induction heating machine utilizes electromagnetic induction to heat electrically conductive materials, such as metals, offering a flame-free, fast, and clean heating method. This technology is crucial across various industries. Canroon's Induction Heating Solutions plays a pivotal role in sectors like automotive, food processing, and metalworking. The global market for these machines is expanding, with projections reaching USD 2.8 billion by 2032. Ambrell Induction Heating provides intelligent digital induction heating systems that ensure precision and efficiency. Whether you require an induction heater brazing machine or an induction heater machine, Ambrell's solutions are designed to meet diverse industrial needs.

Understanding Induction Heating Machines

Induction heating machines are marvels of modern technology, offering a flame-free and efficient way to heat metals. To truly understand how these machines work, you need to delve into their components and the science behind them.

Components of an Induction Heating Machine

An induction heating machine consists of several key components that work together seamlessly:

Power Supply

The power supply is the heart of any induction heating system. It converts electrical energy into a high-frequency alternating current. This current is crucial because it generates the electromagnetic field necessary for heating. The Induction Heating Power Supplies are designed to provide precise control over the heating process, ensuring efficiency and consistency.

Induction Coil

The Induction Coils are responsible for creating the electromagnetic field. These coils are typically made of copper and are designed to accommodate various workpiece geometries. Innovations in coil design have significantly enhanced the efficiency and versatility of induction heating systems. By understanding how induction coils work, you can appreciate their role in generating the necessary electromagnetic fields for heating.

Workpiece

The workpiece is the material you want to heat. It is placed within the electromagnetic field generated by the induction coil. The material's properties, such as its electrical conductivity and magnetic permeability, determine how effectively it can be heated using the induction heating method.

How Induction Heating Works

To understand how induction heating works, you need to grasp the underlying principles of electromagnetic induction and heat generation.

Electromagnetic Induction Process

Induction heating relies on the principle of electromagnetic induction. When an alternating current passes through the induction coil, it creates a rapidly changing magnetic field. This field induces eddy currents in the workpiece. These currents flow through the material, generating heat due to the material's resistance. The efficiency of this process depends on the induction heating frequency, which is carefully controlled to optimize heating.

Heat Generation Mechanism

The heat generation mechanism in induction heating is both precise and efficient. The eddy currents generated in the workpiece cause localized heating. This allows you to heat specific areas without affecting the entire object. By understanding how induction heating work, you can appreciate its ability to provide precise temperature control, making it ideal for applications like metal hardening and brazing.

Applications of Induction Heating Machines

Induction heating finds applications in both industrial and consumer sectors. By understanding how induction heating machines work, you can appreciate their versatility and efficiency.

Industrial Applications

Induction heating machines play a crucial role in various industrial processes. These machines offer precise control and efficiency, making them indispensable in many sectors.

Metal Hardening

You can use an induction heater machine for metal hardening, a process that enhances the durability and strength of metal components. The induction heating method allows you to heat specific areas of a metal workpiece without affecting the entire object. This precision is achieved through the intelligent digital induction heating system, which uses eddy currents to generate heat. By controlling the induction heating frequency, you can achieve the desired hardness and wear resistance in metals.

Welding and Brazing

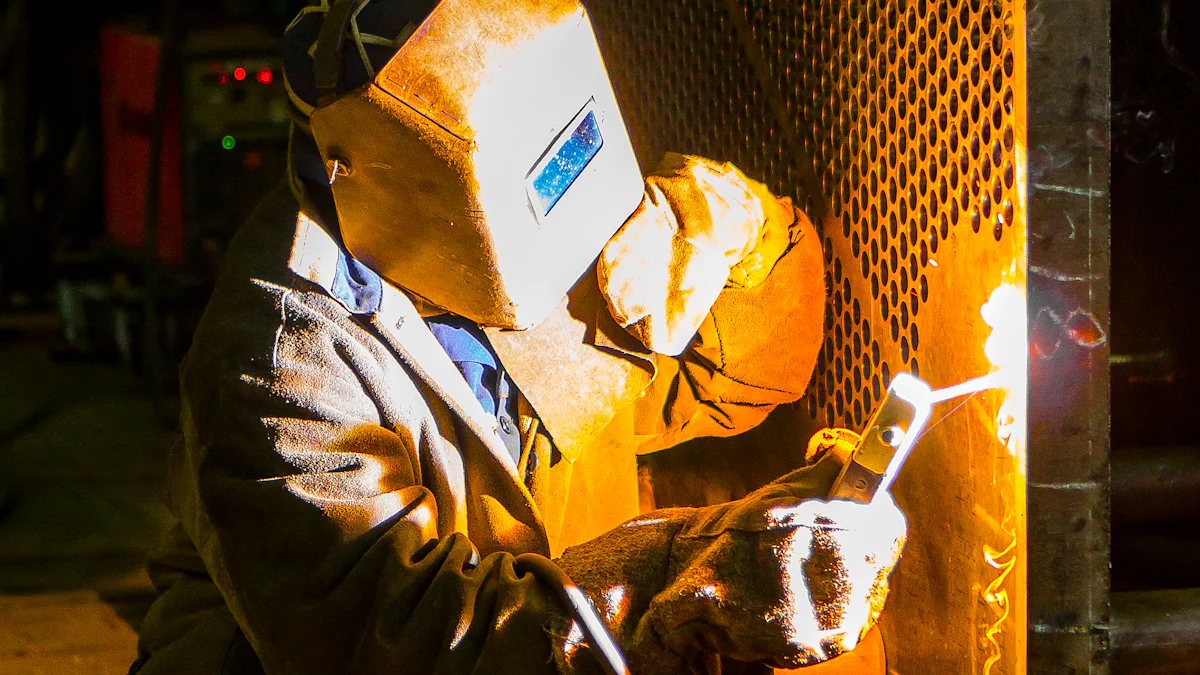

Induction heater brazing machines are essential for welding and brazing applications. These machines provide a clean and efficient way to join metals. The induction heating method ensures that the heat is concentrated only where it's needed, reducing the risk of distortion or damage to the surrounding areas. You can adjust the frequency to suit different materials and thicknesses, ensuring a strong and reliable bond.

Consumer Applications

Induction heating technology has also made its way into consumer products, offering convenience and efficiency in everyday tasks.

Induction Cooktops

Induction cooktops have revolutionized the way you cook. These appliances use an induction heating system to heat pots and pans directly, rather than the cooktop surface. This method is not only faster but also safer, as the cooktop remains cool to the touch. The intelligent induction heating system allows for precise temperature control, making cooking more efficient and enjoyable.

Automotive Uses

In the automotive industry, induction heating machines are used for various applications, including preheating for welding and shrink fitting. The induction heater machine provides a quick and efficient way to heat components, ensuring a perfect fit and reducing assembly time. By understanding how induction heating works, you can see its benefits in improving the performance and reliability of automotive parts.

Benefits of Induction Heating Machines

Induction heating machines offer numerous advantages that make them a preferred choice in various industries. By understanding these benefits, you can appreciate why the induction heating method stands out as an efficient and effective solution.

Efficiency and Speed

Induction heating machines excel in efficiency and speed. You achieve much higher efficiency with induction heating compared to fossil fuels or radiant heating systems. The induction heater machine converts electrical energy directly into heat, minimizing energy loss. This process ensures rapid heating, allowing you to complete tasks faster. The intelligent digital induction heating system provides precise control over the induction heating frequency, optimizing the heating process for different materials and applications. This efficiency makes induction heating the best and most profitable heating alternative for the long term.

Precision and Control

The precision and control offered by induction heating machines are unmatched. You can deliver heat precisely to specific areas of a workpiece without affecting adjoining components. This precision is crucial in applications like metal hardening and brazing, where maintaining the integrity of the workpiece is essential. The induction heater brazing machine allows you to adjust the induction heating frequency to suit different materials, ensuring consistent results. With intelligent induction heating, you achieve the desired temperature with accuracy, reducing the risk of warpage or distortion.

Safety and Cleanliness

Safety and cleanliness are paramount in any heating process, and induction heating machines excel in both areas. The flame-free nature of induction heating eliminates the risks associated with open flames, making it a safer option for your work environment. The induction heating method minimizes product warpage and distortion, maximizing product quality. You can complete the induction heating process on the manufacturing floor, reducing time and costs. Additionally, the clean operation of induction heating machines ensures a non-polluting and environmentally friendly process, aligning with modern sustainability goals.

Comparing Induction Heating to Other Methods

When you explore heating technologies, you'll find that induction heating stands out for its efficiency and precision. Let's delve into how induction compares to other common heating methods.

Induction vs. Electric Heating

Induction heating offers several advantages over traditional electric heating. Electric heating typically involves resistance elements that convert electricity into heat, which then transfers to the material. This process can be slow and inefficient, as a significant amount of energy dissipates into the surrounding environment. In contrast, an induction heater machine directly heats the material through electromagnetic induction, minimizing energy loss. This direct approach ensures that you achieve faster heating times and greater energy efficiency.

Moreover, the intelligent digital induction heating system allows for precise control over the induction heating frequency. This precision means you can target specific areas of a workpiece without affecting the entire object. Such control is particularly beneficial in applications like metal hardening and brazing, where maintaining the integrity of the workpiece is crucial. The induction heating method also reduces the risk of overheating, which can lead to material degradation.

Induction vs. Gas Heating

Gas heating, while widely used, presents several challenges that induction heating effectively addresses. Gas heating relies on combustion, which can introduce safety hazards and environmental concerns. The open flames associated with gas heating pose risks in industrial settings, and the combustion process can release pollutants into the atmosphere.

In contrast, induction heating is a flame-free and clean alternative. The induction heater brazing machine uses electromagnetic fields to generate heat, eliminating the need for combustion. This method not only enhances safety but also aligns with modern sustainability goals by reducing emissions. Additionally, induction heating machines are more compact and versatile, making them suitable for a wide range of applications.

The intelligent induction heating system provides unparalleled efficiency. By directly targeting the material, you minimize wasted energy and reduce processing times. This efficiency translates to lower energy costs and a more environmentally friendly operation. The induction heating frequency can be adjusted to suit different materials, ensuring optimal performance across various applications.

Choosing the Right Induction Heating Machine

Selecting the right induction heating machine requires careful consideration of several factors. You need to ensure that the machine meets your specific needs and delivers optimal performance. Here's a guide to help you make an informed decision.

Assessing Frequency Requirements

When choosing an induction heater machine, you must assess the frequency requirements. The frequency determines how effectively the machine can heat different materials. High-frequency induction heating machines are ideal for small, delicate parts, while low-frequency machines work better for larger components. You should consider the material's properties and the desired heating depth. By understanding these factors, you can select an intelligent induction heating system that provides precise control over the heating process.

Determining Power Needs

Power is a critical factor in selecting an induction heater machine. You need to determine the power requirements based on the size and type of workpieces you plan to heat. Higher power levels allow for faster heating and are suitable for large-scale industrial applications. However, smaller projects may require less power. You should evaluate the machine's power capacity to ensure it aligns with your operational needs. An intelligent digital induction heating system offers flexibility in power settings, allowing you to adjust according to your specific requirements.

Considering Application Specifics

The application specifics play a vital role in choosing the right induction heating machine. You should consider the type of processes you intend to perform, such as metal hardening, welding, or brazing. For instance, an induction heater brazing machine is designed for precise and efficient metal joining. You should also consider the environment in which the machine will operate. Factors like space constraints, ventilation, and safety regulations can influence your choice. By understanding your application's unique demands, you can select an intelligent induction heating machine that meets your needs.

"Choosing the right induction heating machine involves understanding your specific requirements and the capabilities of the machine," says ENRX, a leader in induction heating technology. ENRX induction heating systems offer advanced solutions tailored to various industrial applications.

Canroon's Intelligent Induction Heating Machines

Overview of Canroon's Products

Canroon stands as a leader in the field of induction heating technology. The company offers a range of innovative products designed to meet the diverse needs of various industries. You will find Canroon's solutions widely used in sectors such as shipbuilding, aviation, and automobile manufacturing. The CR1000 Series Intelligent Induction Heating System exemplifies Canroon's commitment to excellence. This system provides precision heating with an electricity-heat transformation rate exceeding 95%. It ensures reliability with a service life of over 50,000 hours, making it ideal for demanding applications like metal melting and forging.

Canroon's products are not only efficient but also versatile. The CR1000 Series features multiple heating modes, allowing you to adapt to different industrial requirements. Its rapid start time of less than 0.2 seconds ensures quick and efficient operation. With advanced overload protection, the system safeguards itself during use, providing peace of mind. Canroon's dedication to quality is evident in its comprehensive warranty and support, offering a 1-year warranty on core components.

Unique Features and Innovations

Canroon's induction heating machines boast several unique features and innovations that set them apart. The CR1000 Series incorporates cutting-edge technology to deliver exceptional performance. You will appreciate its advanced overload protection, which provides 120% protection for one minute and instant protection at 150%. This feature ensures the machine's longevity and reliability, even under challenging conditions.

The system's design prioritizes ease of use and adaptability. It operates effectively at altitudes below 1000 meters, with a power derating of 15% for every additional 1000 meters. This adaptability makes it suitable for various environments. The machine can withstand a relative humidity of less than 90% without condensation, ensuring consistent performance.

Canroon's commitment to sustainability is evident in its environmentally friendly design. The induction heating method eliminates the need for open flames, reducing safety hazards and environmental impact. The clean operation aligns with modern sustainability goals, making Canroon's machines a responsible choice for your industrial heating needs.

In summary, Canroon's intelligent induction heating machines offer a blend of efficiency, versatility, and innovation. Whether you require precision heating for metalworking or reliable solutions for industrial applications, Canroon's products deliver unmatched performance and value.

Induction heating machines offer a transformative approach to heating, providing efficiency, precision, and safety across various applications. You have learned about their components, working principles, and diverse uses in both industrial and consumer sectors. If you're considering purchasing an induction heating machine, evaluate your specific needs and application requirements. Explore Canroon's advanced solutions, like the CR1000 Series, for reliable and efficient heating systems. Remember, while induction heating excels in many areas, it may not suit every application. Assess your options carefully to ensure the best fit for your needs.

Please give us a message