News

PID control helps maintain accuracy in Variable Frequency Drives (VFDs) by optimizing VFD on PID settings. A PID controller adjusts motor speed to ensure stability, which saves energy and prevents system instability. Properly configuring VFDs with effective PID settings ensures they operate smoothly, avoids excessive fluctuations, and reduces energy consumption.

Key Takeaways

PID controllers help keep Variable Frequency Drives (VFDs) steady. They change motor speed to save energy and avoid problems.

Tuning PID settings correctly is very important for VFDs to work well. Adjust proportional, integral, and derivative settings to improve how the system works.

Use methods like Ziegler-Nichols and Cohen-Coon to tune PIDs. These methods find the best settings to keep your system running smoothly and efficiently.

Basics of PID Control in VFD Applications

What is a PID controller, and how does it work?

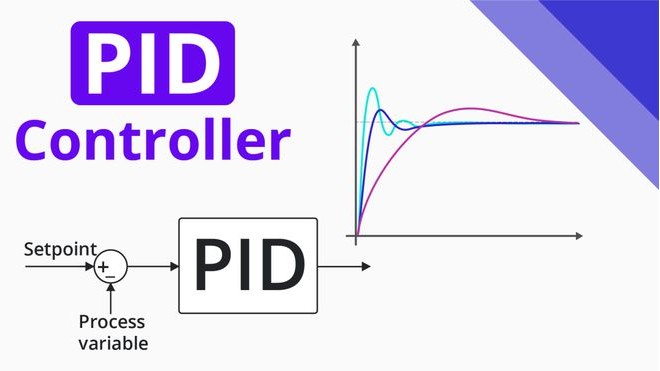

A PID controller is a device that helps control systems. It changes outputs to fix errors and keep things steady. It uses three actions: proportional, integral, and derivative. Proportional control fixes errors by adjusting based on the current difference. Integral control looks at past errors to fix long-term problems. Derivative control predicts future errors by checking how fast things change. This helps stop big jumps or overshoots.

In variable frequency drives, PID controllers control things like speed or pressure. They watch and adjust constantly to keep everything smooth and efficient. Unlike simple controls, PID controllers handle changes better, making them great for tricky tasks.

Roles of Proportional, Integral, and Derivative terms in VFD systems

Each part of a PID controller has a job in VFDs. Proportional control fixes errors right away by reacting to the current problem. For example, if motor speed is wrong, it adjusts based on how big the error is. Integral control fixes small errors over time by looking at past mistakes. Derivative control keeps things steady by reacting to how fast errors are changing. This stops sudden jumps or swings.

In real life, like in HVAC systems, these parts work together. Proportional control changes motor speed quickly. Integral control makes small fixes over time. Derivative control stops sudden changes, keeping everything balanced.

How PID controllers maintain process variables in VFDs

PID controllers help keep things like flow, temperature, or pressure steady. They use proportional, integral, and derivative actions to stay close to the goal. For example, in a pump system, the controller changes motor speed to keep flow steady, even if demand changes.

By watching feedback and making small changes, PID controllers keep systems stable and efficient. This is very important for saving energy and staying accurate in many applications.

Tuning PID Parameters for Variable Frequency Drives

Why tuning is critical for VFD performance

Tuning a PID controller is very important for VFDs. It helps the system work well and stay steady. Adjusting proportional, integral, and derivative terms makes the system respond quickly. This also reduces overshoot and stops too much movement. The motor can then keep the right speed, position, or pressure.

Experts suggest focusing on three main PID parts. Proportional control changes output based on current errors. Integral control fixes long-term errors by looking at past mistakes. Derivative control reacts to how fast errors change, stopping sudden jumps. These adjustments make the system smooth and efficient.

Common challenges in tuning PID controllers for VFDs

Tuning PID controllers can be tricky for many reasons. Noise and system changes can mess up feedback, making control harder. Bad integral timing can make the system slow or unstable. Derivative control is sensitive to noise, causing strange behavior.

To fix these problems, use good timing and tuning methods. Techniques like Ziegler-Nichols or Cohen-Coon can help meet goals. Testing different PID settings can also find the best balance for your system.

Impact of improper PID settings on motor efficiency and stability

Wrong PID settings can hurt motor efficiency and stability. If proportional control is too high, the system may move too much. Bad integral tuning can make responses slow or leave errors. Poor derivative settings can increase noise, causing odd actions. These problems waste energy and lower efficiency.

Good PID tuning helps the motor work its best. It saves energy, keeps the system steady, and protects equipment. This improves performance and lowers costs over time.

Methods for Tuning PID Controllers in VFD Systems

Ziegler-Nichols tuning method for VFDs

The Ziegler-Nichols method is a common way to tune PID controllers. First, set the integral and derivative terms to zero. Next, increase the proportional gain until the system starts steady oscillation. This gain is called the ultimate gain (Ku), and the time of one oscillation is the ultimate period (Tu). Use these values with formulas to find PID settings.

This method works well for general systems that can handle some oscillation. But it may not be the best for systems needing fast or precise control.

Cohen-Coon tuning method and its application in VFDs

The Cohen-Coon method is another way to tune PID controllers. It starts with a stable system and uses a step change to find key settings. This method works well for systems that balance themselves over time. It gives quick responses, making it useful for many applications.

However, this method has limits. It may not work well in systems with big oscillations. You might need other methods to handle those. Still, it’s a good choice for fast and stable control in VFD systems.

Manual tuning techniques with examples for VFD systems

Manual tuning lets you adjust PID settings by watching how the system behaves. Follow these steps to tune manually:

Slowly increase Kp until the system reacts quickly but doesn’t overshoot too much.

Add Ki to fix steady-state errors. Watch for instability or oscillations.

Add Kd if needed to reduce overshoot and smooth out oscillations. Be careful, as too much Kd can cause noise issues.

Adjust all gains in small steps, testing the system after each change.

Test the system with different settings and disturbances to ensure it works well.

This method gives you control and helps you find the best settings for your system.

Practical Tips for Optimizing PID Settings in VFD Applications

Handling fast-changing process variables

Fast-changing variables can make systems unstable and slow to respond. Try these tips to improve PID settings:

Use feedforward control to react faster. It adjusts flows to match changes, keeping things smooth.

Pick the right PID setup for your process. For example, use PI and D on error for normal tasks or adjust for special batch processes.

Tune loops in order. Start with upstream controllers, then move downstream. This avoids problems between loops.

These steps help keep control steady and prevent overshooting or delays.

Dealing with slow process variable changes

Slow changes need a different plan to keep systems efficient. Follow these ideas:

Make sure the main loop settles five times slower than the secondary loop.

Filter the main variable to stop small changes from affecting the secondary set point.

Use filtered set points to ignore tiny, short-term changes.

Add feedforward signals to handle known changes. Adjust feedforward gain slowly to avoid overreacting.

Use high-quality signal cards for better accuracy and less noise.

These methods help keep speeds steady and reduce system changes.

Real-world PID tuning tips for VFD systems

Tuning PID controllers in real life can be tricky. Avoid mistakes like using default settings, wrong control actions, or incorrect units. Also, watch out for sensor delays or filter effects that can mess up adjustments.

To tune well, check your PID gains and keep them within limits. Test the system in different situations to ensure it stays stable and works well. These tips help improve speed and position control while keeping the system efficient.

Knowing PID control is key for better VFD performance. Good PID tuning saves energy and keeps systems steady. To set it up well, smooth out process changes and handle set points smartly. Try methods like Ziegler-Nichols to find settings, then adjust manually for the best results.

FAQ

Why use PID controllers in VFD systems?

PID controllers keep things steady, like speed or pressure. They adjust motors to save energy and avoid problems.

How do you set PID settings for better VFD performance?

First, change proportional gain for quick reactions. Next, add integral gain to fix small errors. Then, use derivative gain to stop overshooting. Test and tweak for the best results.

Please give us a message