News

Portable induction heating equipment has revolutionized industries in 2025. The market, valued at $1.2 billion in 2023, is projected to grow at a CAGR of 8.5%. Industries demand eco-friendly, energy-efficient solutions. These machines deliver precise, rapid heating with minimal energy loss, making them indispensable for applications like Induction Heating Equipment for Pipe.

Key Takeaways

Portable induction heaters save energy by heating materials directly. This lowers wasted energy and cuts costs.

These devices are small and light, perfect for use on-site. They are useful in construction, car-making, and airplane industries.

They work with smart tech to track performance and predict fixes. This makes them safer and more efficient to use.

Understanding Portable Induction Heating Equipment

What is induction heating equipment?

Induction heating equipment uses electromagnetic induction to generate heat in electrically conductive materials. This process involves placing the material in a dynamic magnetic field created by an alternating current. The magnetic field induces eddy currents within the material, which produce heat due to resistance losses, also known as Joule heating. For magnetic materials, additional heat is generated through hysteresis losses caused by molecular friction during magnetization. This method ensures precise and efficient heating without direct contact or open flames, making it safer and more controlled than traditional methods.

Key features of portable induction heating machines

Portable induction heating machines are compact, lightweight, and designed for mobility. These machines often weigh less than 50 kilograms, making them easy to transport and store. They feature quick setup capabilities, requiring minimal installation time. Many models include air-cooled systems, which eliminate the need for complex water-cooling setups. Despite their small size, they deliver power outputs ranging from 1 to 50 kW, suitable for tasks like shrink fitting, brazing, and field repairs. Advanced models integrate basic to intermediate control systems, enabling precise temperature adjustments for various applications. Their portability and efficiency make them ideal for on-site and remote operations.

How it differs from traditional heating methods

Portable induction heating machines differ significantly from traditional heating methods. Unlike open-flame or resistance heating, induction heating generates heat directly within the material, reducing energy loss and improving efficiency. Traditional methods often require prolonged heating times and expose materials to uneven temperatures. In contrast, induction heating provides rapid, uniform heating, minimizing thermal stress. Portable machines also excel in mobility and ease of use. While stationary induction heaters are designed for high-volume tasks in fixed locations, portable models cater to smaller-scale, on-site applications. Their compact design and air-cooled systems make them more versatile and user-friendly.

Benefits of Portable Induction Heating Machines

Energy efficiency and reduced operational costs

Portable induction heating machines offer remarkable energy efficiency and sustainability. These machines minimize energy consumption by generating heat directly within the material, reducing waste. Features like automatic power adjustment and energy-saving modes further enhance their efficiency. Businesses benefit from significantly lower operating costs, making these machines a cost-effective solution for long-term use. Compared to traditional heating methods, induction heating equipment ensures precise heating with minimal energy loss, which is crucial for industries aiming to optimize resources.

Portability for on-site and remote applications

The portability of induction heating machines makes them indispensable for on-site and remote applications. Their compact and lightweight design allows workers to transport them easily to different locations. This mobility is especially valuable in industries like construction, where preheating welding joints or performing post-weld heat treatments often occur in remote or challenging environments. Portable machines eliminate the need for bulky equipment, enabling efficient operations even in confined spaces. High frequency induction heating systems, often integrated into portable models, provide rapid and precise heating, ensuring consistent results regardless of location.

Versatility in industrial and non-industrial use cases

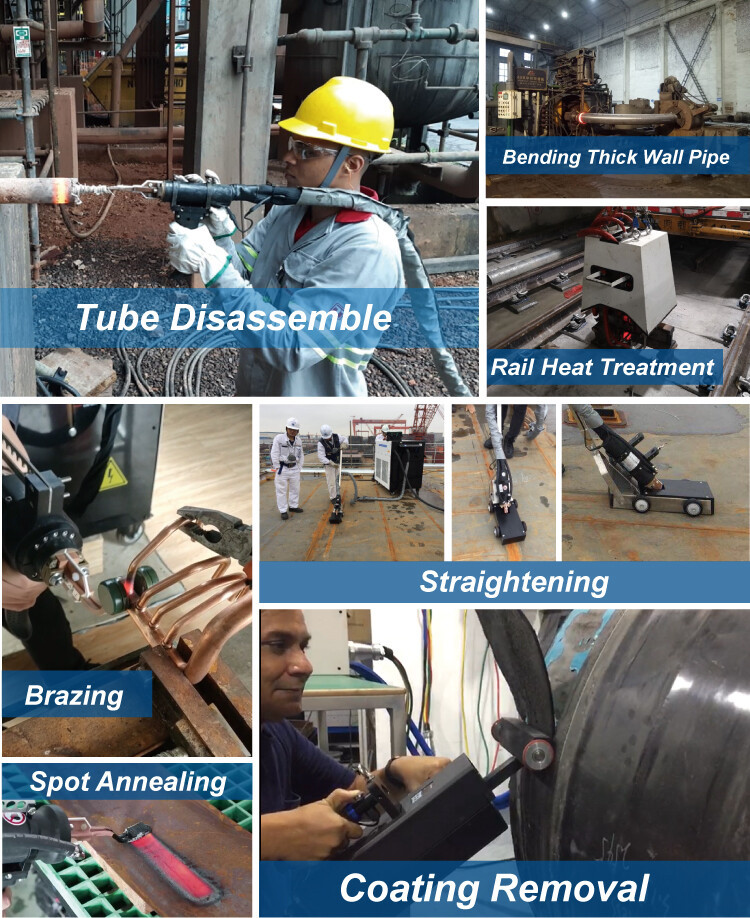

Portable induction heating machines excel in versatility, serving a wide range of applications across industries.

Metal Fabrication: Bending, hardening, tempering, and brazing metal components.

Automotive Repair: Removing and installing bearings, gears, and other parts.

Aerospace: Heat-treating turbine blades and other precision components.

Construction: Preheating welding joints and post-weld heat treatment.

Medical: Sterilization, sealing, and manufacturing medical devices.

Electronics: Soldering and brazing electronic components.

These machines also find use in food processing, where ultra high frequency induction heating ensures precise thermal processing. Their adaptability makes them a valuable tool for both industrial and non-industrial applications.

Technological Advancements in Induction Heating Equipment

Integration with Industry 4.0 and IoT for smarter systems

The integration of Industry 4.0 technologies has transformed induction heating machines into smarter, more efficient systems. These machines now feature IoT capabilities, enabling real-time monitoring and predictive maintenance. Operators can track performance metrics, such as temperature and energy consumption, through connected devices. This connectivity allows seamless integration into industrial IoT (IIoT) networks, optimizing production workflows. Advanced control systems provide customization and flexibility, ensuring precise heating for diverse applications. Smart automation further enhances operational efficiency by reducing manual intervention and enabling data-driven decision-making. These advancements in power electronics and software algorithms ensure consistent temperature regulation, improving both safety and productivity.

Enhanced automation and precision in heating processes

Automation has significantly improved the precision and efficiency of induction heating equipment. Modern systems integrate seamlessly into production lines, enabling continuous operations with minimal downtime. Precise control over power, frequency, and duration ensures accurate temperature profiles, which are critical for high-quality results. Enhanced monitoring and data logging capabilities allow operators to maintain consistency across heating cycles. By reducing manual labor requirements, automation not only increases efficiency but also minimizes human error. High frequency induction heating systems, in particular, benefit from these advancements, as they deliver rapid and uniform heat distribution for demanding applications.

Innovations tailored for automotive, aerospace, and other industries

Recent innovations in portable induction heating machines have expanded their applications in the automotive and aerospace sectors. These industries demand energy-efficient solutions for processes like brazing, hardening, and preheating. Portable systems meet these needs by providing rapid, clean, and consistent heating. The shift toward electric vehicles has further increased demand for these machines, as they play a crucial role in manufacturing and maintaining EV components. In aerospace, ultra high frequency induction heating ensures precise treatment of turbine blades and other critical parts. These advancements in power electronics have made portable systems indispensable for high-precision tasks, driving their adoption across industries.

Market Trends Shaping the Future

Rising demand in automotive, aerospace, and metal processing sectors

The demand for induction heating continues to grow in industries like automotive, aerospace, and metal processing. In the automotive sector, the focus on lightweight materials and advanced manufacturing techniques has increased the need for portable induction heating equipment. These machines play a vital role in processes such as brazing, hardening, and preheating, ensuring better quality control and production efficiency. The shift toward electric vehicles (EVs) has further amplified this demand. Induction heating equipment is now essential for manufacturing and maintaining EV battery systems and electric drivetrains.

In aerospace, the precision and efficiency of high frequency induction heating make it indispensable for manufacturing and repairing aircraft components. These systems ensure high-quality results while reducing maintenance costs. The industry's emphasis on operational efficiency has driven the adoption of portable solutions for tasks like heat-treating turbine blades. Metal processing also benefits from ultra high frequency induction heating, which provides rapid and uniform heating for applications like forging and annealing.

Sustainability as a key driver for adoption

Energy efficiency and sustainability have become critical factors influencing the demand for induction heating. Industries face increasing pressure to adopt eco-friendly practices and reduce their carbon footprints. Portable induction heating machines address these concerns by minimizing energy loss and providing precise control over heating processes. This efficiency reduces operational costs and environmental impact. Additionally, these systems eliminate the need for flames or gas, creating safer and more comfortable work environments. As global sustainability initiatives gain momentum, the adoption of induction heating technologies is expected to rise, helping industries comply with stringent environmental regulations.

The shift towards compact and mobile heating solutions

The market trends and insights reveal a growing preference for compact and mobile heating solutions. Portable induction heating equipment offers flexibility and convenience, making it suitable for various industrial and non-industrial applications. These systems save space by being easy to transport and set up, even in confined areas. Their mobility proves invaluable for temporary infrastructure, such as event tents or remote construction sites. In agriculture, portable systems like the Power Box combine heating and drying capabilities, enhancing versatility. The low planning costs and minimal construction effort required for these machines make them accessible for both new and existing facilities. This shift toward mobility aligns with the increasing demand for induction heating in diverse settings.

Overcoming Challenges in Adoption

Addressing cost barriers for small and medium enterprises

Small and medium enterprises (SMEs) often face significant cost barriers when adopting portable induction heating equipment. The high initial investment required for these machines can deter businesses with limited capital. Advanced models, while offering superior performance, come with a substantial upfront cost compared to traditional heating methods. This financial challenge often outweighs the long-term savings and efficiency benefits these machines provide.

To address this issue, manufacturers are introducing more affordable entry-level models. Financing options, such as leasing or installment plans, are also gaining popularity. These solutions help SMEs access high frequency induction heating technology without straining their budgets. Additionally, governments and industry organizations are offering subsidies and tax incentives to encourage the adoption of energy-efficient technologies, further reducing the financial burden on smaller enterprises.

Bridging the skills gap for operating advanced machines

The operation of advanced induction heating equipment requires specialized knowledge. Many industries struggle with a skills gap, as workers may lack the training needed to operate these machines effectively. This gap can lead to inefficiencies and underutilization of the equipment's capabilities.

To bridge this gap, manufacturers are incorporating user-friendly interfaces and automated features into their machines. Training programs, both online and in-person, are being developed to educate workers on the principles of high frequency induction heating. Some companies are also leveraging augmented reality (AR) for interactive training, allowing operators to gain hands-on experience in a virtual environment. These initiatives ensure that workers can confidently and efficiently use the equipment.

Tackling technological limitations with ongoing innovation

Technological limitations, such as the need for precise control and energy management, have historically hindered the broader adoption of portable induction heating machines. However, ongoing innovations are addressing these challenges.

Modern systems now feature intelligent control systems powered by AI, enabling real-time monitoring and optimization. Improved sensors and feedback mechanisms ensure precise temperature control, enhancing the quality of heating processes. Hybrid heating technologies, which combine induction with other methods, are emerging to improve performance in complex applications. Additionally, advancements in energy efficiency and sustainability are reducing emissions and operational costs, making these machines more appealing to industries.

These innovations are transforming induction heating equipment into versatile and reliable tools, capable of meeting the demands of diverse industrial workflows.

Portable induction heating equipment has transformed industries with its efficiency, precision, and versatility. These machines reduce energy consumption, improve productivity, and create safer work environments. Industry 4.0 integration enhances their functionality through real-time monitoring and predictive maintenance. Sustainability remains a driving force, as eco-friendly solutions gain prominence. Emerging industries, like automotive and aerospace, will continue to adopt these technologies, ensuring their evolution aligns with modern manufacturing needs.

FAQ

What industries benefit the most from portable induction heating equipment?

Industries like automotive, aerospace, construction, and metal processing benefit significantly. These machines provide precise, efficient heating for tasks such as brazing, hardening, and preheating.

How does portable induction heating improve energy efficiency?

Portable induction heating generates heat directly within materials, reducing energy loss. Features like automatic power adjustment further optimize energy consumption, lowering operational costs.

Are portable induction heating machines safe to use?

Yes, they are safe. These machines eliminate open flames and direct contact, reducing risks. Advanced models include safety features like temperature controls and automatic shut-off systems.

Please give us a message