News

Taking care of your induction bolt heater isn’t just about keeping it running—it’s about saving money, staying safe, and ensuring reliable performance. Whether you’re using a portable induction heater or a larger bolt heating machine equipment, proper maintenance helps you avoid costly repairs and keeps your induction heater working like new for years.

Key Takeaways

Clean the heating coils after every use to avoid dirt buildup.

Check your induction heater often for damage like torn insulation or strange sounds.

Use only parts approved by the maker to keep it safe and working well.

Understanding the Induction Bolt Heater

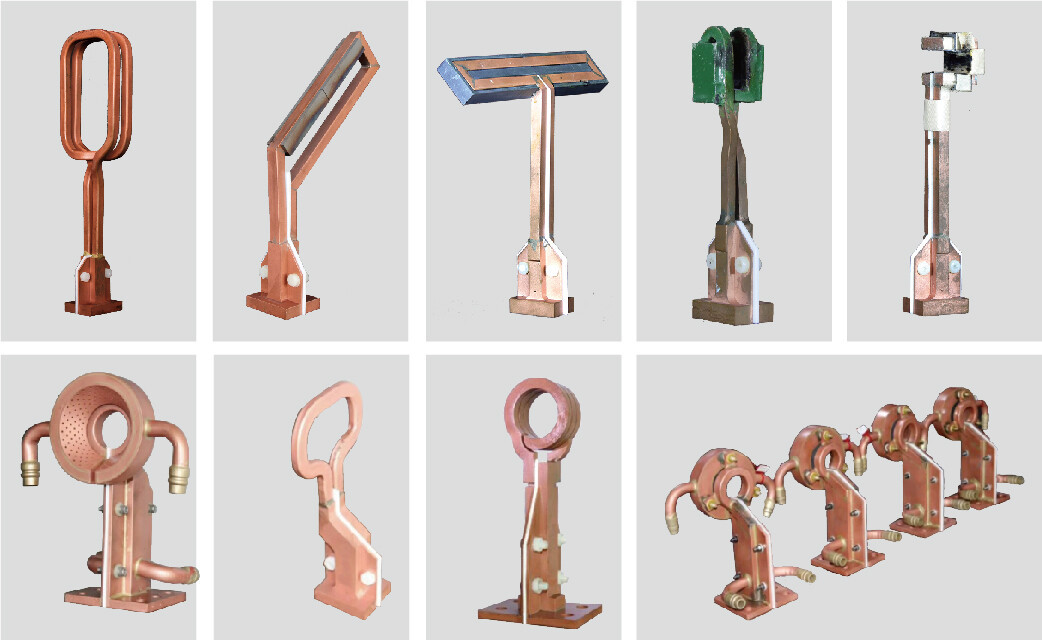

Key Components and Their Roles

To get the most out of your induction bolt heater, it’s important to know how its key components work together. Each part plays a specific role in ensuring efficient and reliable operation. Here’s a quick breakdown:

Induction Coil: This is the heart of the heater. It generates the magnetic field that heats the bolt quickly and evenly. Without it, the heating process wouldn’t be possible.

Power Supply: This provides the electrical current needed to power the induction coil. It also lets you control the heating process, so you can adjust the temperature as needed.

Water Cooling System: Heating generates a lot of heat (no surprise there!). The cooling system keeps the induction coil from overheating by circulating water to remove excess heat.

When these components work together, your induction heater delivers precise and consistent performance. Understanding their roles helps you spot potential issues early and keep your equipment in top shape.

Importance of Induction Heating Technology in Bolt Heaters

Induction heating is what makes your induction bolt heater so effective. This technology uses electromagnetic induction to heat bolts quickly and precisely. Why does that matter? Let’s break it down:

It heats bolts faster than traditional methods, saving you time during maintenance.

The process is highly controlled, allowing bolts to expand just enough for easy removal or tightening.

It focuses heat only where it’s needed, protecting bolt threads and nearby components from damage.

Induction heating tools are energy-efficient, which means lower operating costs for you.

This technology is especially useful in high-pressure applications where precision and safety are critical. By relying on induction heating, you’re not just simplifying bolt maintenance—you’re also ensuring a safer and more efficient process.

Proper Induction Heating Coil Usage

Operating Within Recommended Limits

To get the best out of your induction heater, you need to operate it within its recommended limits. Induction heating coils can handle high temperatures, but they’re not invincible. After several heating cycles, the coils don’t always cool down to room temperature. The critical areas can reach up to 100°C, which is safe for the materials used but can still cause wear over time. Rapid heating and cooling cycles lead to expansion and contraction, creating stress on the coils. To avoid this, manage temperature variations carefully. For instance, let the coil rest between cycles or heat for 5-10 seconds at a time to reduce thermal fatigue. This small step can make a big difference in extending the coil’s lifespan.

Ensuring Proper Setup and Alignment

Proper setup is key to ensuring your induction heater works efficiently. Start by aligning the induction coil with the bolt or workpiece. Misalignment can lead to uneven heating, which wastes energy and reduces performance. Make sure the workpiece is centered and positioned correctly within the coil. Also, double-check that the coil is securely attached to the power supply. A loose connection can cause inconsistent heating or even damage the equipment. Taking a few extra minutes to set everything up properly saves you from headaches later.

Avoiding Common Operational Mistakes

Mistakes during operation can shorten the life of your induction heating coils. Here are a few common ones to watch out for:

Underheated parts: Check for water clogs, worn insulation, or improper coil shape.

Overheated parts: Ensure the coil design matches the application and that the cooling system is working.

Inconsistent heating: Verify the coil alignment and the workpiece’s position.

Coil overheating: Regularly inspect the cooling system and airflow.

Power supply issues: Use a coil that’s compatible with your power supply and inspect connections often.

By following these proper usage tips, you can avoid overheating, improve efficiency, and keep your induction heating tools in great shape.

Maintenance Tips to Extend Induction Heating Coil Life

Cleaning the Induction Heating Coils After Use

Keeping your induction heating coils clean is one of the best practices to maximize coil life. After every use, clean the inductor to remove polymer quench and scale before they dry. This simple step prevents buildup that could affect performance. Every six months, flush the internal water cooling path with a cleaning solution like Lime-A-Way or CLR. This removes calcium deposits that can clog the system. Regular cleaning also keeps the coil shiny, which makes it easier to spot cooling issues early. By following these tips, you’ll ensure your induction heater stays in top condition.

Inspecting for Wear and Damage

Frequent inspections are essential to extend induction heating coil life. Look for frayed or missing insulation on the coils. Damaged insulation can lead to arcing, which may cause sparking and even burn out your induction heater. These issues not only reduce efficiency but also pose safety risks. Catching wear and tear early helps you avoid costly repairs and keeps your induction heating tools running smoothly.

Maintaining the Cooling System and Control Panel

The cooling system plays a critical role in protecting your induction coil from overheating. Check the water flow regularly to ensure it’s circulating properly. If you notice blockages or reduced flow, clean the system immediately. Don’t forget to inspect the control panel for loose connections or faulty settings. A well-maintained cooling system and control panel will help you get the most out of your induction heating tools.

Storing the Heater in a Safe Environment

Proper storage is just as important as regular maintenance. Store your induction bolt heater in a clean, dry environment to protect it from dust and moisture. Avoid placing it near heavy machinery or areas with high vibrations, as these can damage the internal components. Use a protective cover to shield the induction heater from accidental bumps or scratches. Safe storage ensures your equipment is ready to perform whenever you need it.

Identifying Signs of Wear and Tear

Reduced Heating Efficiency

Have you noticed your induction heater taking longer to heat bolts? This could be one of the first signs of normal wear and tear. Reduced heating efficiency often points to issues with the induction heating coils. Over time, these coils can lose their ability to generate a strong magnetic field. Dirt, debris, or even minor damage can interfere with their performance. If your heater isn’t delivering the same results as before, it’s time to inspect the coils and clean them thoroughly. Regular maintenance and proper usage can help you avoid this problem.

Visible Damage to Induction Heating Coils or Cables

Take a close look at your induction heating coils and cables. Do you see cracks, frayed insulation, or discoloration? These are clear signs of wear. Damaged coils or cables can lead to overheating, which might cause your heater to fail unexpectedly. Don’t ignore these warning signs. Replace damaged parts immediately to prevent further issues. Always use manufacturer-approved components to ensure compatibility and safety. A quick visual inspection after each use can save you from costly repairs down the road.

Unusual Noises or Vibrations During Operation

Does your induction heater sound different lately? Unusual noises or vibrations during operation are red flags. These could mean loose connections, misaligned components, or internal damage. Ignoring these signs can lead to bigger problems, like reduced performance or complete failure. If you hear anything out of the ordinary, stop using the heater and check for the source of the issue. Following these tips can help you catch problems early and keep your equipment running smoothly.

Replacing Parts and Components

When to Replace Induction Heating Coils or Cables

Knowing when to replace parts like heating coils or cables is crucial for keeping your induction heater in top shape. Over time, these components wear out due to constant use and exposure to high temperatures. If you notice reduced heating efficiency, visible damage, or unusual noises during operation, it’s time to act. Don’t wait for complete failure. Replacing worn-out parts early prevents bigger problems and keeps your induction bolt heater running smoothly. Regular inspections can help you catch these issues before they escalate.

Sourcing and Installing Manufacturer-Approved Parts

When it’s time to replace parts, always go for manufacturer-approved components. These parts are designed specifically for your induction heater, ensuring compatibility and safety. Using generic or low-quality replacements might save you money upfront, but they can lead to poor performance or even damage your equipment. Check your user manual or contact the manufacturer to find the right parts. Once you have them, follow the installation instructions carefully. This ensures everything fits and functions as it should.

Importance of Professional Assistance for Replacements

Some replacements, like installing new coils or repairing cables, might seem simple. But if you’re unsure, it’s better to call a professional. Experts have the tools and knowledge to handle these tasks safely and efficiently. They can also spot other potential issues during the process. Hiring a professional might cost more, but it saves you from making mistakes that could damage your induction heater. Think of it as an investment in your equipment’s long-term performance.

Taking care of your induction bolt heater doesn’t have to be complicated. Regular maintenance, like cleaning the coils after every use and inspecting for wear, keeps your induction heater running smoothly. Use the right-size coil, secure it properly, and apply heat in short cycles to avoid damage. Proactive care, such as checking for alignment and addressing issues early, saves you from costly repairs. By following these steps, you’ll ensure your equipment stays efficient and reliable for years to come.

FAQ

How often should you clean the induction heating coils?

You should clean the coils after every use. This prevents buildup and ensures optimal performance. Regular cleaning also helps you spot potential issues early.

Can you use generic parts for replacements?

No, always use manufacturer-approved parts. Generic parts might not fit properly or could damage your heater. Stick to approved components for safety and reliability.

What’s the best way to store your induction bolt heater?

Store it in a clean, dry place. Use a protective cover to prevent dust and scratches. Avoid areas with high vibrations or heavy machinery nearby.

Please give us a message