News

Maintaining your frequency converter ensures optimal performance and extends its lifespan. Regular inspections help you spot wear, damage, or overheating early. Cleaning the unit prevents dust buildup, which can lead to overheating. Monitoring operating temperatures keeps the system within safe limits. By updating firmware and tightening connections, you improve reliability and efficiency.

Proactive care reduces downtime and costly repairs. Troubleshooting minor issues early prevents them from escalating into major problems. For example, a 750KW Wide Voltage Range Frequency Inverter benefits significantly from consistent maintenance, ensuring it operates at peak efficiency.

Key Takeaways

Regular cleaning and visual inspections are crucial to prevent overheating and ensure optimal performance of your frequency converter.

Maintaining proper ventilation and monitoring operating temperatures can significantly extend the lifespan of your frequency converter.

Establish a preventive maintenance schedule that includes cleaning, inspecting connections, and updating firmware to enhance reliability and efficiency.

Maintenance Tips for Frequency Converters

Regular Cleaning and Visual Inspections

Keeping your frequency converter clean is essential for optimal performance. Dust and dirt can accumulate on vents, cooling fans, and internal components, leading to overheating. Use compressed air to remove debris from these areas. Ensure the surrounding environment is clean and free from contaminants. If possible, install the unit in a dust-free space or use protective enclosures.

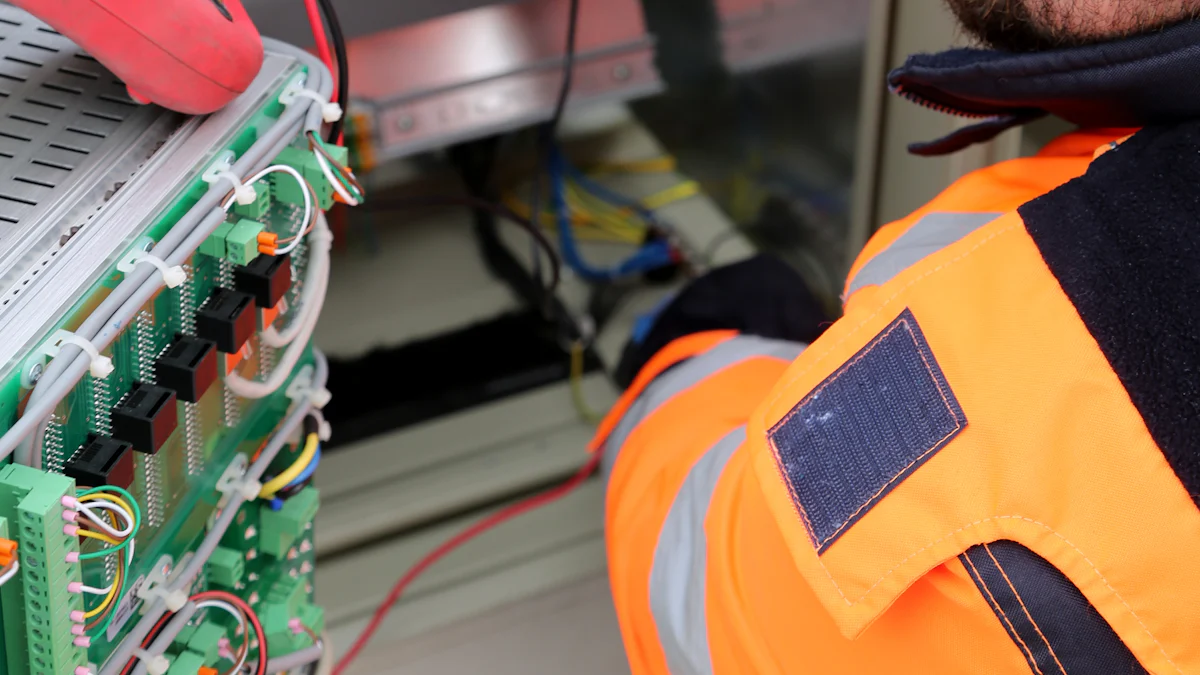

Visual inspections are equally important. Check for signs of wear, discoloration, or physical damage. Loose wiring connections can cause electrical faults or inefficiencies. Tighten any loose connections and inspect for burnt or cracked components. These issues can prevent the frequency converter from operating correctly.

Tip: Prevent significant dirt buildup on the heatsink to maintain proper cooling and avoid over-temperature problems.

Ensuring Proper Ventilation

Proper ventilation prevents overheating and extends the lifespan of your frequency converter. Monitor the operating temperature and keep it within the manufacturer’s recommended range. Install adequate ventilation or air conditioning if necessary. Regularly inspect cooling fans and heat sinks to ensure they function properly.

Overheating reduces performance and shortens the operational life of your frequency converter.

Monitoring Electrical Connections

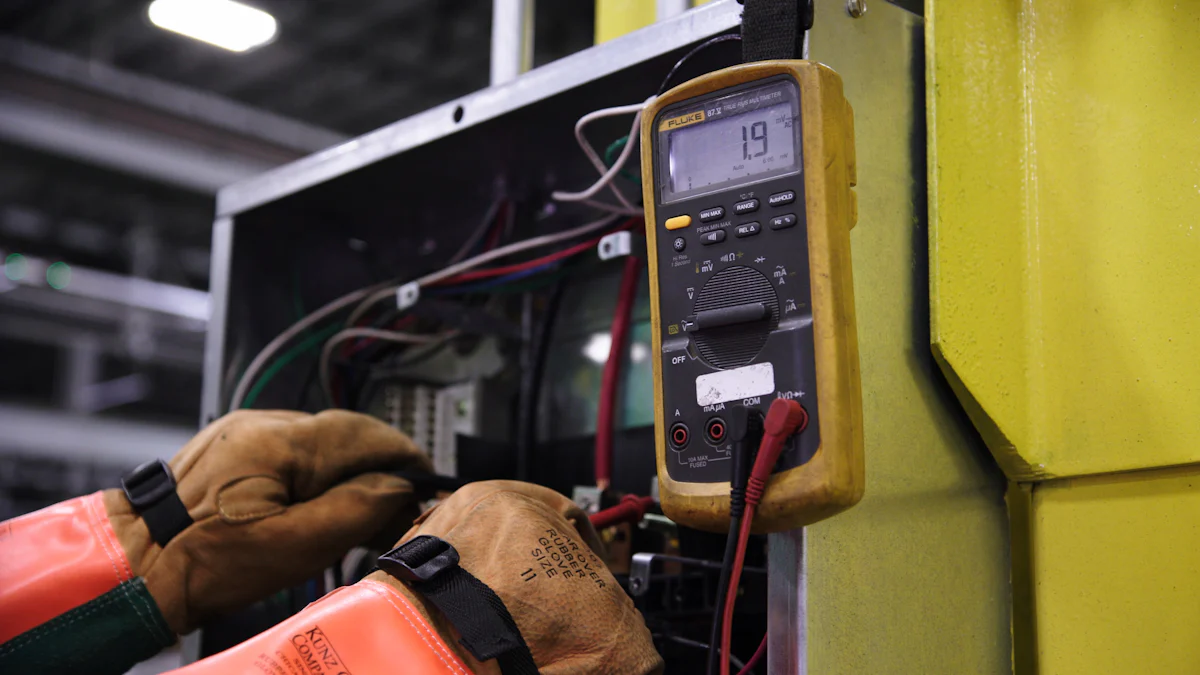

Loose or faulty electrical connections can lead to overheating, erratic performance, or overcurrent faults. Regularly inspect all connections for tightness and corrosion. Tighten power and control wiring as needed. Burned terminals or damaged components should be replaced immediately to avoid further issues.

Common signs of loose connections include unpredictable speed fluctuations and frequent power-related errors.

Updating Firmware and Software

Updating firmware and software improves the efficiency and reliability of your frequency converter. Updates often introduce new features, fix bugs, and address vulnerabilities. Neglecting updates can lead to inefficiencies and security risks. Check for updates regularly and apply them as part of your maintenance routine.

Scheduling Preventive Maintenance

A preventive maintenance schedule ensures your frequency converter operates smoothly. Include tasks like cleaning, inspecting for damage, tightening connections, and checking for software updates. Conduct annual inspections for loose screws, short circuits, and capacitor leaks. Replace worn-out components to avoid unexpected failures.

Regular maintenance reduces downtime and prevents costly repairs.

Troubleshooting Frequency Converter Issues

Diagnosing Overheating Problems

Overheating is a common issue in frequency converters. It can lead to shutdowns or permanent damage if not addressed promptly. Common causes include:

Poor ventilation

Blocked air filters

Overloading

Faulty cooling fans

To diagnose overheating, look for warning signs like excessive heat or system shutdowns. Use the following table to identify causes and solutions:

Tip: Regularly inspect cooling fans and filters to prevent overheating and extend the life of your frequency converter.

Resolving Power Supply Issues

Power supply problems can cause frequent trips, startup failures, or power-related errors. These issues often stem from:

Voltage fluctuations

Loose connections

Faulty capacitors or rectifiers

Follow these steps to resolve power supply issues:

Check wiring connections and tighten any loose ones.

Monitor input power quality to ensure balanced voltages.

Replace faulty capacitors or rectifiers to stabilize the power supply.

Prevention: Use surge protection and inspect wiring regularly to avoid recurring power issues.

Addressing Motor Control Errors

Motor control errors can disrupt operations and reduce efficiency. Common issues include motors not starting, overcurrent trips, or excessive noise. Use diagnostic tools like a Megger to test motor systems and monitor parameters such as voltage and current. Adjust incorrect settings, repair faulty wiring, or replace damaged components to resolve these errors.

Note: Routine inspections and proper setup can prevent most motor control errors.

Fixing Communication Failures

Communication failures occur when the frequency converter cannot connect with external systems. Causes include incorrect settings, damaged cables, or electrical interference. To fix these issues:

Verify communication protocols and settings.

Replace damaged cables or connectors.

Use shielded cables and proper grounding to reduce interference.

Tip: Test cables regularly and ensure compatibility during setup to avoid communication errors.

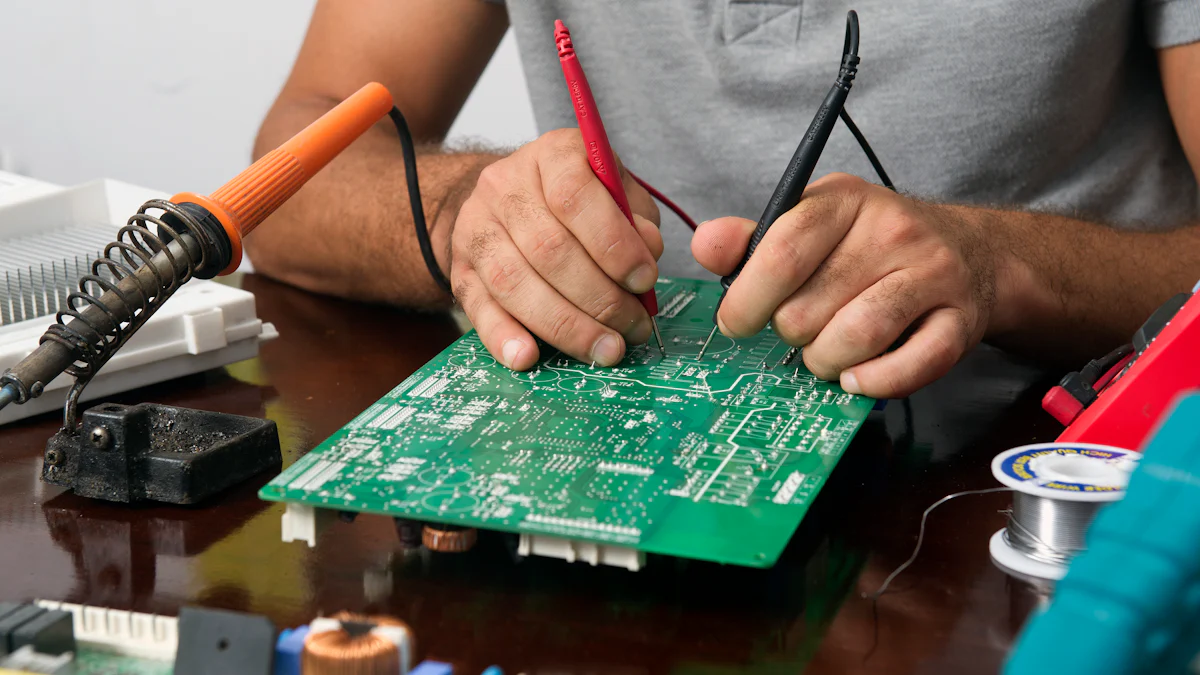

Replacing Faulty Components

Faulty components can compromise the performance of your frequency converter. Replace cooling fans every 2-3 years and check filter capacitors annually. Replace capacitors if their capacity drops by more than 20%. Inspect main contactors for arcs or oxidation and replace them if necessary.

Regular component replacement ensures your frequency converter operates efficiently and avoids unexpected failures.

Regular maintenance improves efficiency, reduces wear, and enhances reliability. You benefit from better energy efficiency, lower costs, and extended equipment lifespan. Troubleshooting efficiently minimizes downtime. Start by checking the environment, cleaning the unit, and inspecting connections. Proactive care ensures your frequency converter operates smoothly, saving you time and money in the long run.

Tip: Prevent frequent tripping by stabilizing the power supply and reducing load.

FAQ

What are the signs that my frequency converter needs maintenance?

Look for unusual noises, overheating, frequent tripping, or inconsistent motor performance. These signs indicate potential issues that require immediate attention.

How often should I clean my frequency converter?

Clean your frequency converter every 3-6 months. If the environment is dusty or humid, increase the frequency to prevent debris buildup.

Can I perform maintenance without professional help?

Yes, you can handle basic tasks like cleaning, inspecting connections, and updating firmware. For complex issues, consult a qualified technician to avoid further damage.

Previous:

Next:

Please give us a message