News

Induction heating solutions offer a versatile approach to meet your industry's unique needs. These solutions can be tailored to provide precise and efficient heating for various industrial applications. Whether you require an Induction Annealing Machine or an Induction Heat Treatment Machine, custom induction heating solutions ensure optimal performance. The global market for these systems is projected to reach USD 1.94 billion by 2024, highlighting their growing importance. Intelligent Digital Induction Heating Systems and Induction Brazing Equipment exemplify the advanced technology available to enhance your operations.

Key Takeaways

Induction heating technology offers precise temperature control, making it ideal for applications like brazing and soldering.

Custom induction heating solutions enhance efficiency by minimizing energy loss and allowing for rapid, localized heating.

Industries such as automotive, aerospace, and food processing significantly benefit from the versatility and reliability of induction heating.

Investing in tailored induction heating equipment can lead to substantial cost savings and improved operational performance.

Choosing the right provider is crucial; consider their experience, product range, and customization options to meet your specific needs.

Induction heating technology supports sustainability goals by reducing energy consumption and lowering carbon footprints.

Understanding Induction Heating Solutions

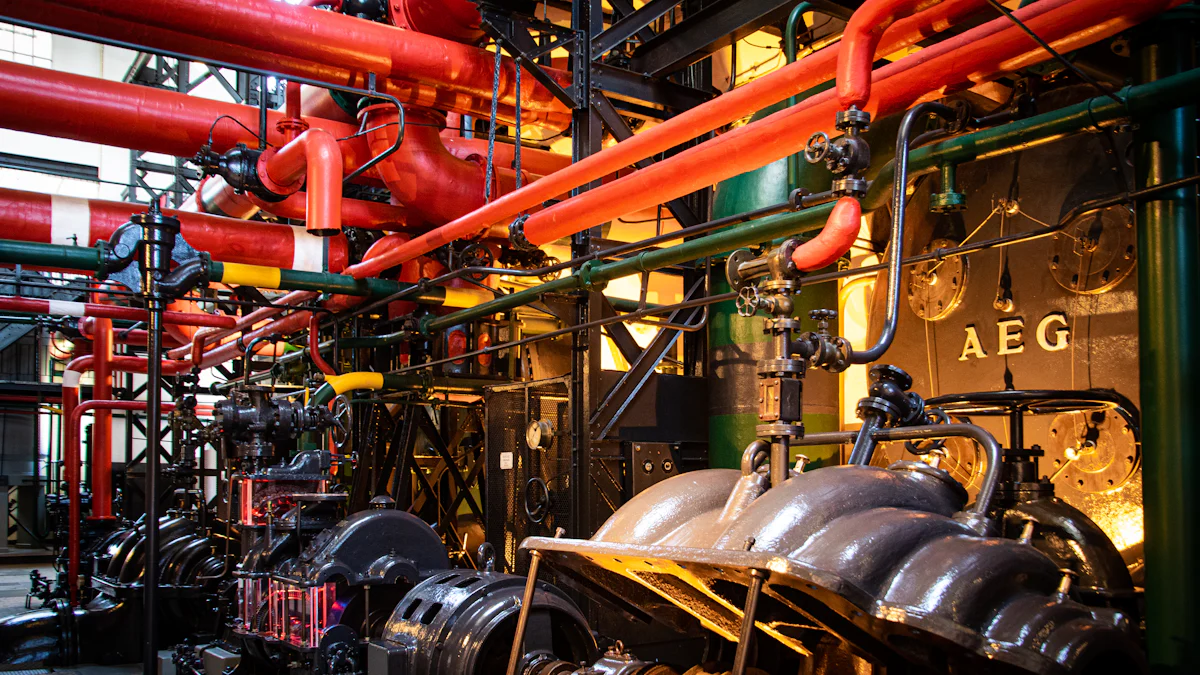

Induction heating technology has revolutionized the way industries approach heating processes. By using electromagnetic fields, this technology heats materials without direct contact, offering a clean and efficient method for various applications. You can find induction heating solutions tailored to meet specific industrial needs, ensuring precision and efficiency.

What is Induction Heating?

Induction heating technology relies on electromagnetic induction to heat conductive materials. When you pass an alternating current through a coil, it creates a magnetic field. This field induces eddy currents in the material placed within the coil, generating heat due to electrical resistance. This process allows for rapid and localized heating, making it ideal for applications where precision is crucial.

The benefits of induction heating technology include:

Precision: You can achieve exact temperature control, which is vital for processes like brazing and soldering.

Efficiency: The technology minimizes energy loss, focusing heat only where needed.

Automation Potential: Induction systems can easily integrate into automated production lines, enhancing productivity.

Localized Heating: You can heat specific parts of a component without affecting the entire piece.

General Induction Heating Applications

Induction heating technology finds use in a wide range of industrial applications. Its versatility makes it suitable for sectors from automotive to aerospace. Here are some common applications:

Metal Heating: You can use induction heating for processes like forging, annealing, and tempering. It provides uniform heat distribution, essential for high-quality metalwork.

Brazing and Soldering: Induction heating offers precise control, ensuring strong and reliable joints in metal components.

Shrink Fitting: This application involves expanding metal parts using heat, allowing them to fit over other components. Once cooled, they form a tight fit.

Heat Treatment: You can use induction heating for hardening and softening metals, improving their mechanical properties.

Industries such as automotive, aerospace, and electronics benefit significantly from induction heating applications. The technology's ability to provide consistent and repeatable results makes it a preferred choice for manufacturers seeking efficiency and quality.

Benefits of Custom Induction Heating Equipment

Efficiency and Precision

Custom induction heating equipment offers unparalleled efficiency and precision in industrial applications. You can achieve precise temperature control, which is crucial for processes that demand accuracy. This technology allows you to focus heat exactly where needed, minimizing energy loss and ensuring optimal results. The rapid heating capability of induction heating technology means you can process more parts in less time, boosting productivity without sacrificing quality.

Induction heating solutions excel in converting electrical energy directly into heat, reducing waste and enhancing energy efficiency. This efficiency translates into higher production rates, allowing you to meet demanding schedules and increase throughput. By investing in custom induction heating solutions, you can tailor the equipment to your specific needs, ensuring that every aspect of the process is optimized for performance and precision.

Cost-Effectiveness and Energy Savings

Custom induction heating solutions are not only efficient but also cost-effective. You can significantly reduce operational costs by minimizing energy consumption and lowering scrap rates. The energy efficiency of induction heating technology can lead to savings of up to 50% or more compared to traditional methods. This reduction in energy use also contributes to a lower carbon footprint, aligning with environmental sustainability goals.

By choosing custom induction heating equipment, you avoid the need for multiple standard units, which can be costly and inefficient. Instead, you get a solution designed to meet your specific requirements, maximizing both performance and cost savings. The precise temperature control offered by induction heating technology ensures repeatable results, reducing the likelihood of errors and further cutting costs associated with rework or waste.

Industries Leveraging Custom Induction Heating Applications

Induction heating technology has become a cornerstone in various industries due to its ability to provide precise temperature control and rapid heating. This section explores how different sectors utilize custom induction heating solutions to enhance their processes and achieve superior results.

Automotive Industry

In the automotive industry, induction heating equipment plays a crucial role in manufacturing processes. You can use it for applications like brazing, hardening, and tempering. These processes require precise temperature control to ensure high-quality outcomes. Induction heating technology offers rapid heating, which significantly reduces assembly time. For instance, when preheating components for welding or performing shrink fitting, you achieve a perfect fit quickly and efficiently. This efficiency not only speeds up production but also enhances energy efficiency, making it a preferred choice for automotive manufacturers.

Aerospace Industry

The aerospace industry demands precision and reliability, and induction heating technology delivers just that. You can find induction heating equipment replacing traditional methods like torch brazing and ovens. This shift is particularly evident in the production of titanium, Inconel, and waspaloy fasteners used in aircraft wings. The precise temperature control offered by induction heating ensures consistent and repeatable results, which are critical in aerospace applications. By leveraging custom induction heating solutions, aerospace manufacturers achieve superior energy efficiency and maintain the high standards required in this sector.

Food Processing Industry

Induction heating technology also finds applications in the food processing industry. You can use it for tasks such as pasteurization and sterilization, where precise temperature control is essential. The rapid heating capability of induction heating equipment ensures that food products reach the desired temperature quickly, preserving their quality and nutritional value. This method enhances energy efficiency by focusing heat only where needed, reducing waste and operational costs. Custom induction heating solutions allow you to tailor the equipment to specific food processing needs, ensuring optimal performance and safety.

Induction heating technology continues to transform industries by offering precise temperature control, rapid heating, and unparalleled energy efficiency. Whether in automotive, aerospace, or food processing, custom induction heating solutions provide the flexibility and reliability needed to meet diverse industrial applications.

Choosing the Right Induction Heating Solution Provider

Selecting the right provider for your induction heating equipment is crucial for achieving optimal results. You need to consider several factors to ensure that the provider can meet your specific industrial needs.

Factors to Consider

Experience and Expertise: Look for a provider with extensive experience in induction heating technology. A seasoned provider understands the nuances of different applications and can offer tailored solutions.

Product Range: Evaluate the range of induction heating products offered. A comprehensive selection indicates the provider's capability to address diverse industrial requirements.

Customization Options: Ensure the provider offers custom induction heating solutions. Customization allows you to get equipment that precisely fits your operational needs, enhancing efficiency and performance.

Energy Efficiency: Consider the energy efficiency of the equipment. Efficient systems reduce operational costs and contribute to sustainability goals.

Support and Service: Reliable customer support is essential. Choose a provider that offers excellent after-sales service and technical support to ensure smooth operation and maintenance.

Questions to Ask Potential Providers

What is your experience with custom induction heating solutions for my industry?

Can you provide case studies or references from similar projects?

How do you ensure precise temperature control in your equipment?

What measures do you take to enhance the energy efficiency of your products?

What kind of support and maintenance services do you offer?

Why Choose Canroon's Induction Heaters for Induction Heating Solutions

Canroon stands out as a leader in the field of induction heating technology. The company offers a range of innovative products designed to meet the diverse needs of various industries. Canroon's intelligent induction heating machines provide a blend of efficiency, versatility, and innovation. Whether you require precision heating for metalworking or reliable solutions for industrial applications, Canroon's products deliver unmatched performance and value.

Canroon's induction heating equipment excels in providing precise temperature control, ensuring that your processes achieve the desired outcomes with minimal energy loss. The rapid heating capability of Canroon's systems allows you to enhance productivity without compromising on quality. Additionally, Canroon's commitment to energy efficiency means that you can reduce operational costs while contributing to environmental sustainability.

Choosing Canroon means investing in a provider that prioritizes quality, versatility, and user-centric design. With a strong focus on customer satisfaction, Canroon offers excellent support and service, ensuring that your induction heating solutions operate smoothly and effectively.

Custom induction heating technology plays a crucial role in optimizing industrial processes. By choosing tailored solutions, you ensure precise temperature control, which is vital for achieving high-quality results. This technology offers rapid heating, enhancing productivity and reducing downtime. Additionally, the energy efficiency of induction heating technology leads to significant cost savings and supports sustainability goals. Exploring custom solutions allows you to address unique heating requirements, ensuring that your operations run smoothly and efficiently. Embrace the advantages of induction heating technology to elevate your industrial applications.

FAQ

What is induction heating technology?

Induction heating technology uses electromagnetic fields to heat conductive materials. When you pass an alternating current through a coil, it creates a magnetic field. This field induces eddy currents in the material within the coil, generating heat due to electrical resistance. This method allows for rapid and localized heating, making it ideal for applications requiring precision.

How does induction heating technology compare to conventional heating methods?

Induction heating technology offers a simple and cost-effective solution. Unlike traditional methods that rely on external heat sources like flames or ceramic elements, induction heating makes the part itself the heating element. This approach delivers fast and consistent heat, ensuring precise temperature control and energy efficiency.

What are the benefits of using induction heating technology?

Induction heating technology provides several advantages:

Precision: You achieve exact temperature control, crucial for processes like brazing and soldering.

Efficiency: The technology minimizes energy loss by focusing heat only where needed.

Automation Potential: Induction systems integrate easily into automated production lines, enhancing productivity.

Localized Heating: You can heat specific parts of a component without affecting the entire piece.

What types of induction heaters are available in the market?

The market offers various types of induction heaters, each designed for specific applications. You can find models tailored for metal heating, brazing, soldering, shrink fitting, and heat treatment. Each type provides unique features to meet diverse industrial needs.

How do I choose the right induction heating solution provider?

When selecting a provider, consider the following factors:

Experience and Expertise: Look for a provider with extensive experience in induction heating technology.

Product Range: Evaluate the range of products offered to ensure they meet your needs.

Customization Options: Ensure the provider offers custom solutions tailored to your requirements.

Energy Efficiency: Consider the energy efficiency of the equipment to reduce operational costs.

Support and Service: Choose a provider with reliable customer support and after-sales service.

Can induction heating technology be used in the food processing industry?

Yes, induction heating technology finds applications in the food processing industry. You can use it for tasks like pasteurization and sterilization, where precise temperature control is essential. The rapid heating capability ensures food products reach the desired temperature quickly, preserving quality and nutritional value.

How does induction heating technology enhance energy efficiency?

Induction heating technology excels in converting electrical energy directly into heat, reducing waste and enhancing energy efficiency. This efficiency translates into higher production rates, allowing you to meet demanding schedules and increase throughput while minimizing energy consumption.

What industries benefit most from induction heating technology?

Industries such as automotive, aerospace, and electronics benefit significantly from induction heating technology. Its ability to provide consistent and repeatable results makes it a preferred choice for manufacturers seeking efficiency and quality.

How does induction heating technology support sustainability goals?

Induction heating technology supports sustainability by reducing energy consumption and lowering carbon footprints. Its efficiency leads to significant cost savings and aligns with environmental sustainability goals, making it an eco-friendly choice for industrial applications.

Please give us a message