News

Circular knitting machines demand precise control to produce high-quality fabric. The CV900N series VFD helps you achieve this by optimizing speed control and enhancing operational stability. It minimizes fabric defects and ensures consistent texture. With advanced precision, you can create textiles that meet industry standards while reducing waste and improving efficiency.

Key Takeaways

The CV900N VFD improves fabric by controlling speed accurately. It reduces mistakes and keeps the texture even.

The CV900N VFD saves energy, cutting costs for factories. It is a smart and eco-friendly option for making textiles.

Adding the CV900N VFD to knitting machines lowers damage. It helps machines last longer and need less fixing.

Understanding the CV900N Series VFD

Overview of the CV900N series VFD

The CV900N series VFD is a high-performance vector frequency inverter designed to enhance the efficiency and precision of industrial machinery. You can rely on its advanced control modes, such as V/F control and speed-sensor-less vector control (SVC), to achieve superior speed regulation and torque response. This makes it ideal for applications requiring high accuracy and stability, including circular knitting machines. Its robust design ensures reliable operation, even under demanding conditions.

This VFD offers a wide range of output voltages (0480V and 0260V) and supports rated power from 0.4KW to 500KW. With a fast dynamic torque response of ≤20ms and high starting torque capabilities, it delivers exceptional performance. The CV900N series VFD also incorporates energy-saving features, reducing power consumption while maintaining optimal functionality.

Key features and technology of the CV900N series VFD

The CV900N series VFD integrates cutting-edge technology to meet the needs of modern textile manufacturing. Here are some of its standout features:

High precision control: Achieve accurate speed and torque adjustments with a built-in PID controller.

Strong overload capacity: Handle up to 150% of the rated current for 60 seconds and 180% for 3 seconds.

Energy efficiency: Save energy with its smart energy-saving function, reducing operational costs.

Low noise operation: Create a quieter working environment, improving operator comfort.

Versatile applications: Suitable for various industries, including textiles, ceramics, and plastics.

By leveraging these features, you can enhance the performance of your circular knitting machines, ensuring consistent fabric quality and operational efficiency.

Role of CV900N Series VFD in Circular Knitting Machines

Importance of precise speed control in knitting machines

Precise speed control is essential for circular knitting machines to produce high-quality fabrics. Variations in speed can lead to uneven knitting, resulting in defects like inconsistent texture or weak fabric strength. The CV900N series VFD addresses this challenge by offering advanced frequency control. With a range of 0 to 500Hz for vector control and up to 5000Hz for V/F control, it ensures smooth and accurate speed adjustments. This level of precision allows you to maintain consistent fabric quality, even during high-speed operations.

High speed stability and accuracy are critical in industrial applications. The CV900N series VFD excels in this area, making it an ideal choice for textile manufacturers. By maintaining stable speeds, it minimizes errors and reduces waste, helping you achieve better production efficiency.

Enhancing operational stability and fabric quality

Operational stability directly impacts the quality of the fabric produced. The CV900N series VFD enhances stability through its robust design and strong overload capacity. Equipped with a built-in PID controller, it provides high precision control, ensuring smooth operation even under demanding conditions.

By integrating these features, the CV900N series VFD ensures consistent fabric texture and reduces the likelihood of defects. Its energy-saving capabilities also make it a sustainable choice for textile manufacturers. With reliable performance and a long service life, you can depend on this VFD to optimize your knitting operations while maintaining high fabric standards.

Benefits of Using CV900N Series VFD

Improved speed control and consistency

The CV900N series VFD allows you to achieve precise speed control, which is essential for maintaining fabric quality. Its advanced control modes ensure consistent operation, even during high-speed production. This consistency reduces errors and minimizes fabric defects. You can rely on its ability to maintain stable speeds, which is critical for producing textiles with uniform texture and strength.

Tip: Consistent speed control not only improves fabric quality but also enhances overall production efficiency.

Enhanced energy efficiency

Energy efficiency plays a vital role in reducing operational costs. The CV900N series VFD incorporates smart energy-saving features that optimize power consumption without compromising performance. By using this VFD, you can lower your energy bills and contribute to a more sustainable manufacturing process. Its ability to adjust energy usage based on operational demands ensures that no power is wasted.

Reduced machine wear and maintenance

Frequent wear and tear can lead to costly repairs and downtime. The CV900N series VFD minimizes mechanical stress on your knitting machines by providing smooth acceleration and deceleration. This reduces the strain on components, extending the lifespan of your equipment. With less frequent maintenance, you can focus more on production and less on repairs.

Better fabric quality through advanced control

Advanced control features in the CV900N series VFD help you produce fabrics with superior quality. Its precise adjustments ensure that every stitch is uniform, resulting in textiles with consistent texture and strength. By reducing defects, you can meet industry standards and satisfy customer expectations.

Note: Investing in advanced control technology not only improves fabric quality but also enhances your reputation as a reliable textile manufacturer.

Real-World Applications of CV900N Series VFD

Implementation in circular knitting machines

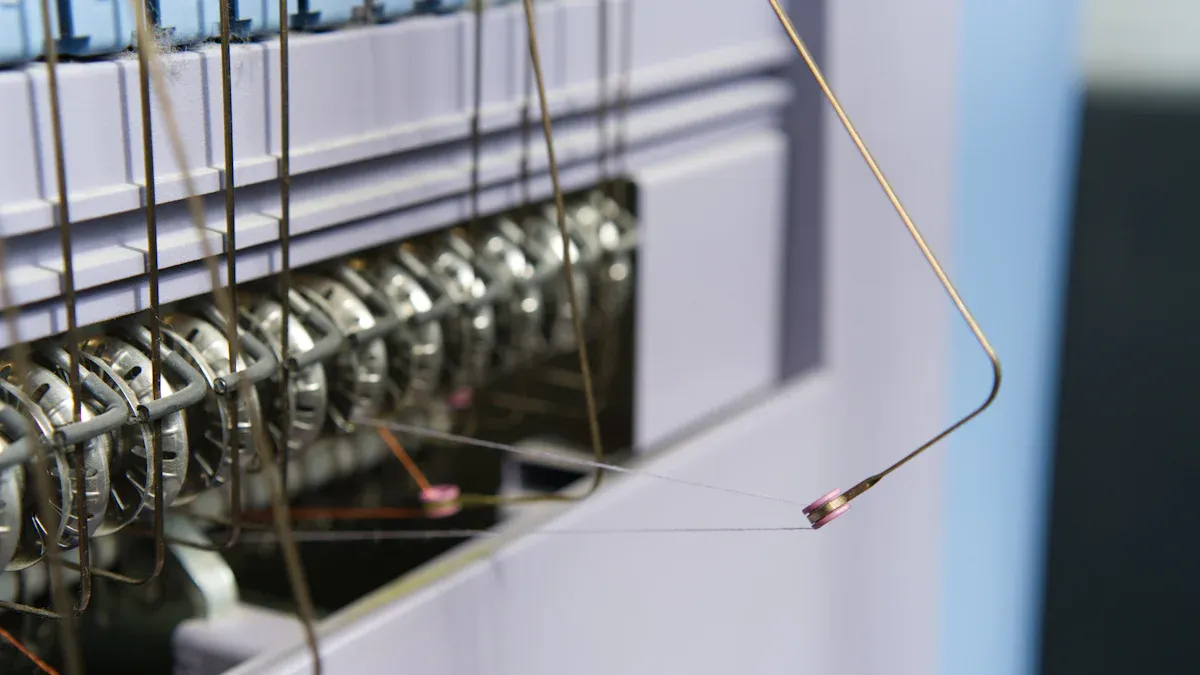

You can integrate the CV900N series VFD into circular knitting machines to achieve precise control and operational efficiency. Its advanced features, such as speed-sensor-less vector control, allow you to regulate machine speeds with exceptional accuracy. This ensures consistent fabric texture and reduces defects during production.

The VFD’s strong overload capacity and high starting torque make it suitable for handling demanding knitting operations. You can rely on its robust design to maintain stability, even under fluctuating load conditions. By optimizing speed and torque, the CV900N series VFD helps you produce textiles that meet industry standards while minimizing waste.

Tip: Regularly monitor the VFD settings to ensure optimal performance and adapt to changing production requirements.

Success stories from textile manufacturers

Textile manufacturers worldwide have experienced significant improvements in fabric quality and operational efficiency by using the CV900N series VFD. One manufacturer reported a 20% reduction in fabric defects after implementing this VFD in their circular knitting machines. Another company noted a 15% decrease in energy consumption, highlighting the VFD’s smart energy-saving capabilities.

These success stories demonstrate how the CV900N series VFD can transform your production process. By reducing machine wear and enhancing control precision, it helps you achieve consistent results and lower maintenance costs. Manufacturers have also praised its durability, which ensures long-term reliability in high-demand environments.

Note: Investing in advanced VFD technology can improve your production outcomes and strengthen your competitive edge in the textile industry.

The CV900N series VFD transforms your textile production by enhancing fabric quality, boosting operational efficiency, and reducing energy costs. Its advanced control features ensure consistent results, fewer defects, and smoother operations. By adopting this technology, you can optimize production, lower expenses, and maintain a competitive edge in the textile industry.

FAQ

What makes the CV900N series VFD suitable for circular knitting machines?

The CV900N series VFD offers precise speed control, strong overload capacity, and energy-saving features. These ensure consistent fabric quality and operational efficiency in knitting machines.

How does the CV900N series VFD reduce fabric defects?

Its advanced control modes maintain stable speeds and accurate torque adjustments. This minimizes errors during production, resulting in fewer defects and uniform fabric texture.

Can the CV900N series VFD help lower energy costs?

Yes! Its smart energy-saving function optimizes power usage based on operational demands. This reduces energy consumption and lowers your overall production costs.

Tip: Regular maintenance of your VFD ensures optimal performance and maximizes energy savings.

Please give us a message