News

Have you ever struggled to remove enamel insulation from wires? High-frequency induction heating makes it easy. This method uses electromagnetic induction to heat and soften the enamel. You can remove it quickly without damaging the wires. It’s precise, fast, and eco-friendly—perfect for working with enameled wire bundles.

Key Takeaways

High-frequency induction heating is an efficient and eco-friendly method for removing enamel insulation from wire bundles, ensuring quick and precise results without damaging the wires.

Proper setup is crucial: ensure your induction heating machine is grounded, the coil fits snugly around the wire bundle, and the power settings match the size of the wires for optimal heating.

Always prioritize safety by wearing heat-resistant gloves, goggles, and clothing, and take the time to clean the wires before heating to avoid common mistakes that can lead to uneven enamel removal.

Tools and Equipment for Depainting Enameled Wire Bundles

Induction heating machine and coil configuration

The induction heating machine is the heart of this process. It generates the high-frequency electromagnetic waves needed to heat the enamel coating. When choosing a machine, you’ll want to consider the size of your wire bundles and your budget. Smaller machines, suitable for light tasks, typically cost between $1,500 and $10,000. Medium-sized machines, which handle larger projects, range from $15,000 to $50,000. For industrial-scale work, machines can exceed $100,000.

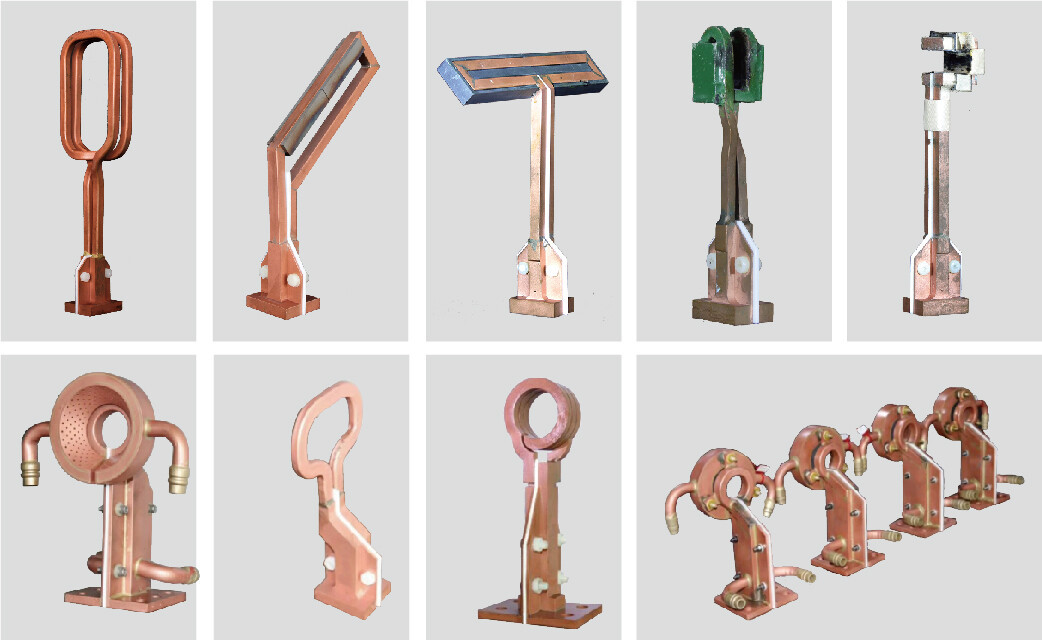

The coil configuration is just as important. The coil surrounds the wire bundle and determines how evenly the heat is applied. You can use a pre-made coil or customize one to fit your specific needs. A well-designed coil ensures the enamel softens evenly without damaging the wires.

Safety gear (gloves, goggles, heat-resistant clothing)

Safety should always come first. High-frequency induction heating generates intense heat, so you’ll need proper protective gear. Heat-resistant gloves protect your hands from burns. Goggles shield your eyes from sparks or debris. Wearing heat-resistant clothing adds an extra layer of protection. Don’t skip these essentials—they keep you safe while you work.

Additional materials (wire holders, cleaning tools, optional immersion tank)

You’ll also need a few extra tools to make the process smoother. Wire holders keep the enameled wire bundles steady during heating. Cleaning tools, like brushes or cloths, help remove softened enamel residue. For larger projects, an immersion tank can be useful for cooling and cleaning the wires after heating. These materials ensure a clean and efficient workflow.

Step-by-Step Process for Depainting Enameled Wire Bundles

Setting up the induction heating machine

Start by setting up your induction heating machine in a safe, well-ventilated area. Place it on a fire-resistant surface to avoid accidents. Make sure the machine is properly grounded and connected to a stable power source. Adjust the power settings based on the size and thickness of your enameled wire bundles. A lower power setting works well for smaller wires, while larger bundles may need higher power. Double-check the coil configuration to ensure it fits snugly around the wire bundle for even heating.

Preparing the wire bundles for heating

Before you begin, secure the wire bundles using pliers or a wire holder. This keeps them steady during the process. Inspect the wires for any dirt or debris and clean them with a cloth if necessary. Proper preparation ensures the enamel softens evenly and reduces the risk of damage to the wires.

Applying high-frequency induction heating

Now comes the fun part! Position the wire bundle inside the coil and turn on the induction heating machine. Watch as the enamel coating softens and bubbles under the heat. This process usually takes just a few seconds. Once the enamel is pliable, use a scraper or cleaning tool to remove it. For larger bundles, you might need to repeat the process to ensure all the enamel is gone.

Cleaning and inspecting the wires post-depainting

After removing the enamel, clean the wires with a solvent to get rid of any residue. Inspect the wires carefully to ensure no enamel remains. Infrared thermal imaging can help with this step, especially for Litz wire. It records temperature profiles during heating and cooling, making it easier to spot any missed spots. This method is highly effective and improves quality control.

Pro Tip: Always inspect your wires under good lighting to catch any leftover enamel. A clean wire ensures better conductivity and easier soldering later.

Tips for Achieving Optimal Results

Choosing the right power settings and coil design

Getting the power settings and coil design right is crucial for clean enamel removal. Start by matching the power level to the size and thickness of your enameled wire bundles. Smaller wires need lower power, while thicker bundles require higher settings. Experiment with these levels to find the sweet spot.

The coil design also plays a big role. A well-fitted coil ensures even heating, which prevents damage to the wires. You can use a pre-made coil or create a custom one for your specific project. If you’re unsure, test the coil on a small section of wire first. This helps you avoid uneven heating or overheating.

Avoiding common mistakes during the process

Mistakes can happen, but you can avoid most of them with a little preparation. One common issue is overheating the wires. This can damage the wire core and make it unusable. To prevent this, always monitor the heating process closely.

Another mistake is skipping the cleaning step before heating. Dirt or debris on the wires can interfere with the process, leading to uneven enamel removal. Take a moment to clean the wires beforehand. It saves you time and frustration later.

Tip: Don’t rush the process. Take your time to set up everything properly. A little patience goes a long way in achieving great results.

Ensuring even heating for clean enamel removal

Even heating is the key to removing enamel without damaging the wires. Here are a few techniques to help you achieve this:

Use thermal strippers set to the right temperature for the enamel coating. These tools remove enamel efficiently without harming the wire.

Try a heat gun or small torch. Move the heat source back and forth along the wire to distribute heat evenly.

Use infrared thermal imaging to inspect the wires. This method records temperature profiles during heating and cooling, helping you spot any missed areas.

By following these tips, you’ll get clean, professional results every time.

High-frequency induction heating offers a reliable and eco-friendly way to depaint enameled wire bundles. It’s cleaner than traditional methods since it doesn’t emit fumes or CO2. Plus, it’s energy-efficient, converting up to 90% of energy into heat. With the right tools and safety gear, you’ll get precise results. Experiment with settings to refine your technique and achieve professional-quality outcomes.

FAQ

What types of wires work best with high-frequency induction heating?

You can use this method on most enameled wires, including copper and aluminum. It works especially well for Litz wire due to its bundled structure.

How do I know if my coil design is effective?

Check for even heating across the wire bundle. Uneven heating means you might need to adjust the coil size or shape for better results.

Tip: Test your coil on a small wire section first!

Previous:

Next:

Please give us a message