News

Accurate frequency measurements are vital for maintaining the efficiency of electrical systems. Electrical grids rely on stable frequencies, such as 50 Hz in Europe or 60 Hz in North America, to ensure smooth power generation and distribution. Even minor deviations can lead to equipment malfunctions or power outages. When you use a multimeter, you can measure the quality of a frequency converter by assessing parameters like AC voltage and no-load current. A stable no-load current during frequency adjustments indicates a well-functioning converter, helping prevent disruptions and ensuring system reliability.

Key Takeaways

Check your multimeter and test wires for damage first. This keeps you safe and makes your readings correct.

Turn your multimeter to the right frequency setting before measuring. This is important to get accurate frequency results.

Calibrate your multimeter often to keep it working well. Calibration stops mistakes and keeps your frequency readings steady.

Safety Precautions for Using a Multimeter

Inspecting the Multimeter and Test Leads

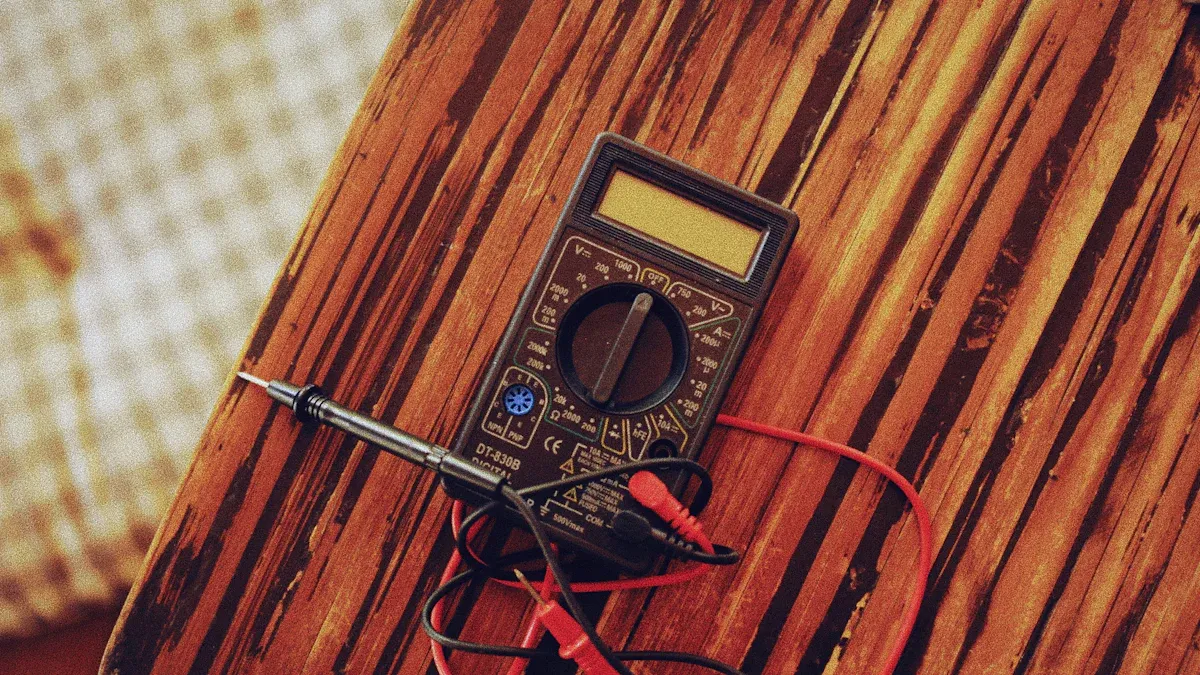

Before using your multimeter, inspect it and the test leads carefully. Look for visible damage, such as cracks in the casing or exposed metal on the probes. Damaged equipment can lead to inaccurate readings or even electrical hazards. Ensure the plugs fit securely and the test leads meet safety standards. Faulty leads, especially those made from dissimilar metals, can cause errors in low-voltage measurements. Always test your multimeter on a known voltage source to confirm it functions correctly.

Ensuring Proper Insulation and Grounding

Proper insulation and grounding are critical for your safety. Use insulated rubber mats to protect yourself from accidental shocks. Ensure the multimeter and its accessories are rated for the voltage you plan to measure. Avoid using the device in damp or humid environments, as moisture can compromise insulation and increase the risk of electrical shock. Following these precautions helps maintain safety and ensures accurate measurements.

Avoiding Contact with Live Circuits

Never assume a circuit is de-energized. Always test it with your multimeter before touching any components. Coming into contact with live circuits can result in severe injuries, including burns or electrocution. High-energy incidents, such as arc flashes, can also occur, releasing molten metal or shrapnel. Use the correct personal protective equipment (PPE), such as insulated gloves and flame-resistant clothing, to minimize risks.

Wearing Safety Gear for Electrical Work

Wearing the right safety gear is essential when working with electrical systems. Use hard hats with electrical insulation, safety glasses, and face shields to protect against debris and arc flashes. Insulated gloves and rubber lineman gloves provide protection against electric shock. Flame-resistant clothing reduces the risk of burns, while safety shoes with non-conductive soles protect your feet. These safety tips are especially important when working with variable frequency drives or other high-voltage equipment.

How to Use a Multimeter to Measure Frequency

Setting the Multimeter to Frequency Mode

To measure frequency accurately, you must first set your digital multimeter to the correct mode. Follow these steps:

Insert the black test lead into the COM jack.

Insert the red test lead into the V Ω jack.

Connect the black test lead to the circuit, followed by the red test lead.

Observe the frequency reading on the display.

If your multimeter has a frequency button, set the dial to AC voltage mode, connect the leads, and press the Hz button to switch to frequency measurement. This setup ensures your multimeter is ready to measure frequency accurately.

Connecting the Probes to the Frequency Converter

Proper probe connection is essential for reliable readings. Begin by powering off the frequency converter and disconnecting its input and output lines. Set your multimeter to the appropriate mode for the parameter you want to measure. For AC voltage, select ACV mode. Attach the black probe to the negative terminal and the red probe to the positive terminal. Ensure the probes make firm contact with the terminals to avoid errors.

Taking and Interpreting Frequency Readings

Once the probes are connected, turn on the frequency converter. The multimeter will display the frequency in hertz. Verify the reading against the expected value for your system. For example, a stable 50 Hz or 60 Hz indicates proper operation. If the reading fluctuates or deviates significantly, it may signal an issue with the converter.

Ensuring Accurate Measurements and Calibration

To maintain accuracy, calibrate your digital multimeter regularly. Use tools like voltage calibrators or resistance decade boxes to verify its performance. Environmental factors such as temperature and humidity can also affect readings. Always perform measurements in a controlled environment to minimize errors. Calibration ensures your multimeter provides reliable results, helping you measure frequency with confidence.

Troubleshooting Frequency Measurement Issues

Resolving Unstable or Distorted Readings

Unstable or distorted readings during frequency measurement often indicate underlying issues. Common causes include improper calibration, environmental factors, or signal interference. For example, electromagnetic interference (EMI) from nearby devices can distort readings. To resolve this, shield your setup and use filters to clean the signals. Regularly calibrate your digital multimeter to ensure accurate readings. Always perform measurements in a controlled environment to minimize temperature and humidity effects.

Checking Probe Connections and Contact Points

Secure probe connections are essential for reliable frequency measurement. Loose or improper connections can cause unstable readings. To improve accuracy:

Use test points to connect the ground clip for a short loop.

Choose probes recommended by your oscilloscope manufacturer.

Verify all connections are secure and appropriate for the setup.

Compensate new probes to the oscilloscope input being used.

These steps help you diagnose electrical problems effectively and ensure accurate readings from your frequency converter.

Verifying Multimeter Calibration and Settings

Calibration ensures your multimeter provides reliable results. Follow these steps to verify calibration:

Set the multimeter to frequency mode and confirm it supports the required range.

Attach the probes securely to the circuit points.

Observe the frequency reading and check for stability.

Regular calibration prevents errors and helps you test for continuity and measure frequency with confidence.

Identifying Electrical Interference and Noise

Electrical interference can disrupt frequency measurement. Common sources include lights, motors, and appliances with high-current switches. Voltage spikes from lightning or substation faults also contribute. To mitigate interference:

Measure high-frequency cable currents with a current probe.

Assess harmonic signals radiating from the product using a nearby antenna.

By addressing these issues, you can test diodes and measure frequency accurately, even in challenging environments.

Using a multimeter to measure the quality of a frequency converter involves several key steps. Inspect your device, set it to frequency mode, and connect the probes securely. Always prioritize safety by powering off circuits when necessary. Practice regularly to build confidence and ensure accurate frequency measurements for reliable system performance.

FAQ

What should you do if your multimeter fails to display a frequency reading?

Check the probe connections and ensure the multimeter is set to frequency mode. Test the multimeter on a known frequency source to confirm functionality.

How often should you calibrate your multimeter for frequency measurements?

Calibrate your multimeter annually or as recommended by the manufacturer. Regular calibration ensures accurate test results and reliable frequency measurements.

Can you use a multimeter to test for electrical interference?

Yes, you can test for interference by measuring unexpected fluctuations in frequency. Use shielding and filters to minimize interference during your tests.

Please give us a message