News

Brazing copper pipes is easier and faster with Canroon's portable handheld heater. This versatile tool, which includes a portable induction heater for metal, offers precise energy control, making it ideal for consistent results. Unlike traditional methods, it heats joints in seconds, saving time and energy. Additionally, its handheld high frequency induction heater design ensures safety and efficiency for every project, especially when using an induction heater used for metal brazing hardening.

Key Takeaways

Collect all tools and materials you need before starting. This helps the brazing process go smoothly.

Make your workspace safe by following safety rules. Remove open flames and make sure there is good airflow.

Check the heater and copper pipes carefully before using them. This prevents problems while brazing.

Preparation for Using a Portable Handheld Heater

Essential Tools and Materials

Before you start brazing copper pipes, gather all the necessary tools and materials. Having everything ready ensures a smooth process and avoids interruptions. Here's a checklist of what you'll need:

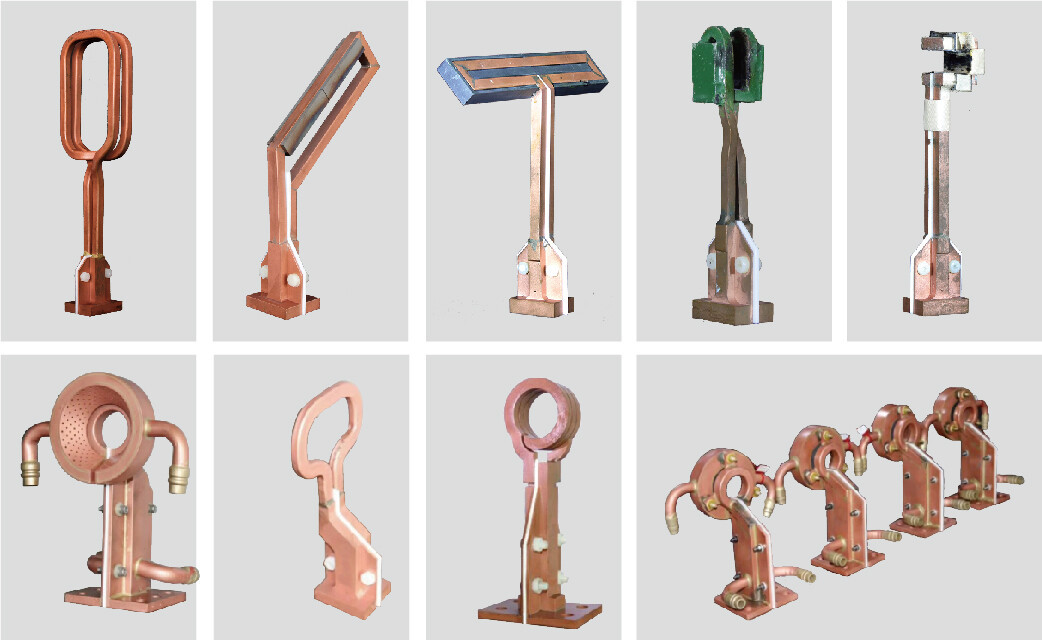

Induction brazing systems for precise and efficient heating.

Medium frequency power supplies, ideal for strand brazing.

Handheld brazing systems, which are portable and eco-friendly.

Pneumatic brazing pistols for safe and accurate operations.

Induction coils, available in custom and standard designs.

Surface preparation tools like tube cutters, reamers, and wire brushes.

Brazing flux to prevent oxidation and improve alloy flow.

Support mechanisms to keep the pipe setup aligned.

Safety equipment, including touch screen power supplies and counterweight mounts.

Having these tools on hand will make your brazing process more efficient and professional.

Setting Up a Safe Workspace

Creating a safe workspace is crucial when using a portable handheld heater. Follow these safety guidelines to minimize risks and ensure high-quality results:

By following these steps, you can create a workspace that prioritizes both safety and efficiency.

Inspecting the Heater and Copper Pipes

Before you begin, inspect the heater and copper pipes to ensure everything is in good condition. Here's what to check:

Look for leaks or damage in the pipes, valves, water heater, and drains.

Take photos of any issues and make notes for reference.

Assign corrective actions for immediate fixes.

Use dielectric unions to connect copper and galvanized pipes, preventing corrosion.

Conduct pressure tests to confirm the plumbing system is functioning correctly.

A thorough inspection helps you avoid potential problems and ensures a successful brazing process.

Step-by-Step Guide to Brazing Copper Pipes

Cleaning and Preparing the Copper Pipes

Before you start brazing, cleaning the copper piping is essential. This step ensures a strong and reliable joint. Follow these best practices:

Use a wire brush or sandpaper to remove oils, grease, and oxides from the pipe's surface.

Inspect the copper pipes for cracks, pits, or other defects after cleaning.

Smooth out any burrs using abrasive tools or solvents.

Check the fit between the pipes. If needed, use clamps to hold them in place.

Proper preparation sets the foundation for successful copper brazing. Skipping this step can lead to weak joints or leaks later on.

Positioning the Portable Handheld Heater

Positioning the portable handheld heater correctly is crucial for even heating. Place the induction brazing unit close to the joint you’re working on. Make sure the induction coil surrounds the pipe evenly. This ensures the heat is distributed uniformly. Keep the heater steady during the process to avoid uneven results.

Heating the Joint and Applying Filler Material

When heating the joint, aim for a quick and consistent process. Research shows that rapid heating with an induction brazing system improves joint strength. It also reduces the risk of material weakening. Once the joint reaches the right temperature, apply the filler material. Let it flow into the gap between the pipes. The filler should bond smoothly without gaps or bubbles.

Cooling and Inspecting the Finished Joint

After brazing, let the joint cool naturally. Avoid rushing this step, as sudden cooling can weaken the bond. Once cooled, inspect the joint thoroughly. Use ultrasonic testing if available. This method helps detect defects like poor bonding or cracks. A well-brazed joint will have a smooth finish and no visible gaps.

Safety Tips for Using a Portable Handheld Heater

Wearing Protective Gear

When brazing copper pipes, safety should always come first. Wearing the right protective gear shields you from potential hazards like heat, sparks, and fumes. Here’s a quick guide to essential safety equipment:

By using this gear, you’ll create a safer environment for yourself and others.

Ensuring Proper Ventilation

Good ventilation is critical when using a portable handheld heater. The brazing process can release harmful fumes, depending on the materials and methods you use. Without proper airflow, these fumes can build up and pose serious health risks. To avoid this, make sure your workspace has adequate ventilation. Open windows, use exhaust fans, or work in an open area whenever possible. Monitoring air quality and keeping exposure levels within safe limits ensures a healthier environment.

Avoiding Overheating and Other Common Mistakes

Overheating is a common issue when using a portable handheld heater. It can weaken the joint or damage the materials. To prevent this, always monitor the temperature closely. Modern induction brazing systems come with features like integrated frequency converters and coolant systems. These designs help maintain consistent heat levels and prevent overheating.

Here are a few tips to avoid common mistakes:

Use the right size and type of induction brazing equipment for your application.

Keep the heater steady to ensure even heat distribution.

Avoid rushing the process; let the joint cool naturally to maintain its strength.

By following these steps, you’ll achieve better results and extend the life of your equipment.

Maintenance and Storage of the Portable Handheld Heater

Cleaning the Heater After Use

After finishing your copper brazing project, cleaning the portable handheld heater is essential. Residue from the brazing process can build up on the heater, affecting its performance over time. Start by letting the heater cool completely. Once it's safe to handle, wipe down the exterior with a soft, damp cloth to remove dust and debris. For stubborn spots, use a mild cleaning solution, but avoid harsh chemicals that could damage the surface. If your heater has detachable components, check the user manual for cleaning instructions. Keeping the heater clean ensures it operates efficiently and lasts longer.

Inspecting for Damage or Wear

Regular inspections help you catch potential issues before they become serious. After each use, examine the heater for signs of wear or damage. Look for frayed cords, loose connections, or cracks in the casing. Pay close attention to the induction coil, as it plays a critical role in the heating process. If you notice anything unusual, address it immediately. Ignoring small problems can lead to bigger ones, potentially affecting your induction brazing results. A quick inspection after every use keeps your equipment in top shape and ensures safety during future projects.

Storing the Heater Safely

Proper storage is just as important as cleaning and inspecting. Always store your heater in a cool, dry place away from direct sunlight or moisture. Avoid stacking heavy items on top of it to prevent damage. For added safety, follow these best practices:

Keep the heater and related supplies in a designated area to avoid clutter.

Ensure the storage space is free from flammable materials.

Refer to safety programs, like the Compressed Gas Cylinder Program, for guidance on storing equipment used in hot work operations.

By storing your heater correctly, you reduce the risk of accidents and extend its lifespan. A little care goes a long way in maintaining your equipment.

Using Canroon's portable handheld heater for brazing copper pipes is straightforward when you follow the right steps. Start with proper preparation, prioritize safety, and maintain your equipment after each use. These steps ensure efficient and reliable results every time.

Please give us a message