News

The variable frequency drive industry, including the variable frequency AC drive segment, is undergoing rapid transformation, driven by market demand for energy efficiency and automation. Forecasts indicate significant growth, with the market expected to reach $24.3 billion by 2025, reflecting a CAGR of 4.8%. IoT and AI integration enable real-time monitoring and predictive maintenance, while renewable energy applications enhance motor performance and energy conversion processes.

Key Takeaways

Variable frequency drives (VFDs) help save energy by adjusting motor speeds. This can cut energy use by as much as 50%.

Adding IoT and AI to VFDs allows real-time tracking. It also helps predict problems, lowering repair costs and boosting efficiency.

Using VFDs helps the environment by cutting carbon emissions and energy waste. They are important for industries aiming to save energy.

Market Trends in 2025

Energy Efficiency as a Market Driver

Energy efficiency remains one of the key factors impacting the market for variable frequency drives in 2025. Industries are increasingly adopting these systems to reduce energy consumption and operational costs. Variable frequency drives optimize motor operations by adjusting speeds to match load requirements, resulting in significant energy savings. This capability has made them indispensable in sectors like HVAC, water treatment, and oil and gas. The low-power drive segment, particularly those under 6 kW, is experiencing rapid growth due to its cost-effectiveness and suitability for small-scale applications. Emerging markets are also driving demand for energy-efficient solutions as industrialization accelerates.

Industrial Automation and Smart Manufacturing

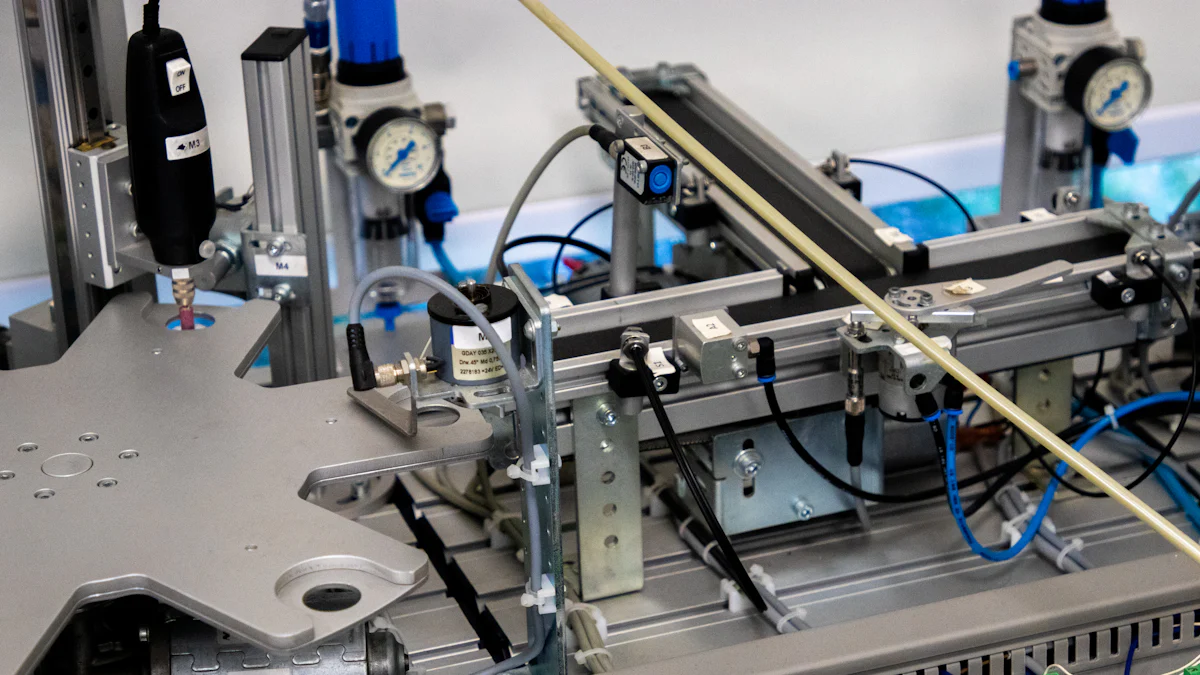

The rise of industrial digitization is transforming the global variable frequency drive market. Integration with IoT and smart technologies enables real-time monitoring and predictive maintenance, reducing downtime and enhancing operational efficiency. Advancements in control algorithms, such as vector control, are improving motor performance and accuracy. Compact designs are gaining popularity, catering to industries with space constraints. These trends are reshaping manufacturing and process industries, where automation and precision are critical. The forecast for 2025 highlights the growing role of variable frequency drives in supporting smart manufacturing initiatives.

Sustainability and Decarbonization Efforts

Sustainability initiatives are reshaping the variable frequency drive market. The industrial sector consumes 37% of global energy, while buildings account for 30%. Variable frequency drives address this challenge by optimizing motor speeds, eliminating wasteful constant-speed operation. This results in lower energy usage, reduced carbon footprints, and cost savings. Industries like manufacturing and HVAC are increasingly adopting these systems to align with decarbonization goals. As global concerns about energy consumption grow, the demand for sustainable solutions continues to rise, positioning variable frequency drives as a cornerstone of future prospects in energy management.

Technological Advancements in Variable Frequency Drives

Enhanced Energy Efficiency and Performance

Variable frequency drives are evolving to deliver superior energy efficiency and performance. These advancements are driven by innovations in control algorithms, such as vector control and direct torque control, which enhance motor precision and reduce energy consumption. By adjusting motor speeds to match operational requirements, these drives minimize wasteful energy usage, supporting sustainability initiatives. The integration of smart technologies further optimizes performance, enabling real-time monitoring and predictive maintenance. These features not only improve operational efficiency but also reduce downtime, making variable frequency drives indispensable in industries like manufacturing and HVAC. As the market trends toward energy-efficient solutions, these advancements position variable frequency drives as a cornerstone of future prospects in energy management.

IoT Integration and Smart Connectivity

The integration of IoT is transforming the functionality of variable frequency drives. These systems now offer enhanced communication capabilities, allowing them to interact with other devices in real time. Technicians can remotely monitor performance data, reducing maintenance costs and improving operational efficiency. IoT-enabled drives also support predictive maintenance strategies, which anticipate potential failures and minimize downtime. Additionally, data integration allows for detailed analysis, enabling process optimization and improved production workflows. These features align with market trends emphasizing automation and smart manufacturing, ensuring that variable frequency drives remain at the forefront of industrial innovation.

AI-Driven Optimization and Predictive Maintenance

Artificial intelligence is revolutionizing the variable frequency drive industry by enabling advanced optimization and predictive maintenance. AI continuously monitors drive performance, identifying potential issues before they lead to equipment failure. This proactive approach ensures uninterrupted operations and extends equipment life. Features like remote monitoring and predictive alerts further enhance system efficiency, reducing mechanical stress and electrical strain. These benefits not only lower maintenance costs but also maximize productivity. As industries adopt AI-driven solutions, variable frequency drives will play a critical role in meeting the growing demand for reliable and efficient systems.

Industry Applications of Variable Frequency Drives

Manufacturing and Process Industries

Variable frequency drives play a critical role in manufacturing and process industries by improving operational efficiency and reducing energy consumption. Industries such as oil and gas, pulp and paper, and water and wastewater management are leading adopters of these systems.

The oil and gas sector relies heavily on motor-driven pumps for production and refining processes. In pulp and paper manufacturing, low-voltage drives enhance efficiency in various operations. Water and wastewater facilities use these drives to optimize pumping systems, reducing energy waste. These industrial applications highlight the growing market trends for energy-efficient solutions in 2025.

HVAC Systems and Building Automation

HVAC systems and building automation increasingly leverage variable frequency drives to achieve energy efficiency. Running motors at partial speeds consumes less energy than intermittent full-speed operation. For example:

A cooling tower fan operating at 80% speed consumes nearly 50% less energy than one running at full speed.

Intermittent operation provides only linear savings, while reducing motor speed offers cubic savings.

These systems also improve operational performance by optimizing motor speeds based on real-time demand. This capability aligns with market trends emphasizing sustainability and cost savings. As buildings account for 30% of global energy consumption, the adoption of variable frequency drives in HVAC systems will continue to grow.

Renewable Energy and Electric Vehicles

Variable frequency drives are essential in renewable energy systems and electric vehicles. In renewable energy, they optimize generator speed, capturing excess energy during wind gusts or braking. In electric vehicles, they manage power flow to recover kinetic energy during braking, converting it into electrical energy to recharge the battery. This process extends the vehicle's driving range.

The renewable energy sector is experiencing steady growth, driven by the need for efficient energy management. Variable frequency drives enable these systems to maximize energy output while minimizing waste. Their role in electric vehicles further underscores their importance in advancing sustainable technologies.

Regional Market Insights for the Variable Frequency Drive Industry

North America’s Market Growth

The variable frequency drive market in North America is experiencing steady growth due to several factors. Industries prioritize energy efficiency and cost savings, driving the adoption of these systems. The increasing demand for automation and process control further accelerates market expansion. Efforts to reduce carbon emissions and comply with government regulations also play a significant role. Policies like the Energy Policy Act (EPAct) provide financial incentives, encouraging industries to invest in variable frequency drives. These trends highlight North America’s commitment to sustainable and efficient industrial practices.

Asia-Pacific as a Key Growth Region

The Asia-Pacific region leads the global variable frequency drive market, driven by rapid industrialization and economic development. Countries like China and India dominate demand due to their focus on energy-saving solutions and infrastructure expansion. Energy-intensive sectors, including wastewater treatment, chemical processing, and oil and gas, rely on variable frequency drives to optimize energy consumption. Substantial investments in research and development by VFD vendors further boost market growth. With a projected compound annual growth rate of 6.5%, the Asia-Pacific region remains a key area for innovation and adoption of variable frequency drives.

Opportunities in Europe and Emerging Markets

Europe and emerging markets present significant opportunities for the variable frequency drive industry. In Europe, stringent energy efficiency standards and government incentives promote the adoption of these systems. Variable frequency drives enable precise motor control, reducing energy consumption and greenhouse gas emissions. The rise of Industry 4.0 technologies also drives demand, as VFDs support real-time monitoring and optimization in smart manufacturing. Additionally, Europe’s investments in renewable energy infrastructure highlight the importance of VFDs in stabilizing electricity delivery. Emerging markets benefit from similar trends, with growing industrial automation and sustainability initiatives creating new opportunities for the variable frequency drive market.

Challenges and Opportunities in the Variable Frequency Drive Market

Addressing High Initial Costs and Complexity

The adoption of variable frequency drives faces several challenges, particularly for small and medium-sized enterprises. High initial investment remains a significant barrier. Many businesses hesitate to adopt this technology due to the upfront costs of equipment and installation. Complexity in integrating variable frequency drives into existing systems adds to the challenge. Retrofitting older systems often requires additional components, increasing downtime and training expenses.

Maintenance and repair costs also pose difficulties. Unexpected component failures can disrupt operations and reduce system efficiency. Electromagnetic interference (EMI) from variable frequency drives may affect nearby electronic devices, necessitating extra shielding measures. Furthermore, overheating issues require effective cooling solutions to maintain performance. Limited expertise in operating and optimizing these systems further complicates adoption. Addressing these challenges will require innovative solutions and industry-wide collaboration.

Leveraging Government Incentives and Regulations

Government policies play a pivotal role in driving the variable frequency drive market. Many regions offer financial incentives to promote energy-efficient technologies. For example, tax credits and subsidies encourage industries to invest in variable frequency drives. Regulations mandating energy conservation also boost adoption. These policies align with global sustainability goals, reducing energy consumption and carbon emissions.

In addition, governments in regions like North America and Europe enforce strict energy efficiency standards. Compliance with these regulations often requires the use of variable frequency drives. By leveraging these incentives and adhering to regulations, businesses can achieve cost savings while contributing to environmental sustainability.

Unlocking Potential in Emerging Markets

Emerging markets present significant opportunities for the global variable frequency drive market. Rapid industrialization and urbanization in regions like Asia-Pacific and Latin America drive demand for energy-efficient solutions. Rising energy costs in these regions make variable frequency drives an attractive investment for reducing operational expenses.

Advancements in variable frequency drive technology further enhance their appeal. Improved performance and expanded application scope make these systems suitable for diverse industries. Governments in emerging economies also implement energy efficiency regulations, encouraging adoption.

By addressing challenges and capitalizing on opportunities, the variable frequency drive market can achieve sustained growth and innovation.

The variable frequency drive industry is poised for remarkable growth in 2025, driven by energy efficiency, automation, and sustainability demands. Businesses investing in these systems can achieve:

Energy savings of up to 50% through optimized motor speeds.

Reduced maintenance costs and extended equipment lifespan.

Enhanced process control and adaptability to varying loads.

Adopting variable frequency drives aligns with global sustainability goals. These systems reduce energy consumption and emissions, contributing to a greener future. By embracing technological advancements and regional opportunities, businesses can secure cost savings, operational efficiency, and environmental benefits.

FAQ

What is a variable frequency drive (VFD)?

A variable frequency drive adjusts motor speed by controlling the frequency and voltage of electrical power, improving energy efficiency and operational performance.

How do VFDs contribute to energy savings?

VFDs optimize motor speeds to match load requirements. This reduces energy waste, lowers electricity costs, and supports sustainability goals in industrial and commercial applications.

Are VFDs compatible with renewable energy systems?

Yes, VFDs enhance renewable energy systems by optimizing generator speeds and managing energy flow, improving efficiency in wind turbines, solar inverters, and electric vehicles.

Previous:

Next:

Please give us a message