News

Zone temperature control helps industries manage heat accurately through methods like electromagnetic induction heating. It divides the system into zones for even or focused heating. New technology and energy-saving needs make it more popular. It offers steady temperature control, saves energy, and makes equipment last longer.

Key Takeaways

Zone temperature control helps industries manage heat better for quality.

It saves energy by heating only needed areas, cutting waste and costs.

Modern systems control many heating zones, improving safety and equipment life.

Understanding Zone Controlled Induction Heating

Principles of Zone Temperature Control

Zone temperature control uses smart methods to spread heat evenly. Here are the main ideas:

Each heating zone has its own power supply for control.

Systems change electricity settings to keep the right heat level.

Special coil designs make heat patterns for better control.

These ideas help industries heat things evenly or in specific spots. By using custom coils and separate power sources, engineers can control heat with great accuracy.

Mechanisms for Managing Heat in Specific Zones

Induction heating systems use clever ways to control heat in zones. One way is by designing coils to heat certain areas of the material. This makes sure each zone gets the right heat amount. For more control, separate coils with their own power supplies are used. This lets each zone work on its own for perfect heat control.

Advanced systems, like Canroon Induction, improve this process. They can control up to four zones separately. Users can turn zones on or off or change their heat levels. Even with challenges like "cross-talk" between coils, these systems keep heating steady and reliable. Industries use these tools to manage heat well in tricky jobs.

The Role of Electromagnetic Induction in Temperature Control

How Induction Heating Generates Heat

Electromagnetic induction heating uses magnetic fields to create heat. A fast-changing magnetic field interacts with conductive materials. This causes electric currents, called eddy currents, to form. These currents make heat because of the material's resistance. In some metals, extra heat comes from resisting magnetic changes. These methods together make heating quick and accurate.

The process starts with an induction heater using high-frequency electricity. This creates a changing magnetic field around it. When a metal object is placed in this field, eddy currents form on its surface. These currents stay near the outer layer, heating it quickly. This method spreads heat evenly, making it great for precise jobs.

Integration of Zone Control with Induction Heating Systems

Zone control improves induction heating by splitting it into sections. Each section has its own coil and power source. This setup allows exact temperature control and saves energy. It also keeps performance steady, even in tough tasks.

Advanced systems solve problems like coil interference, called cross-talk. They can control up to four zones separately in one system. This lets industries adjust heat levels in different areas. It helps save power and focus heat where needed, reducing waste and boosting efficiency.

Applications of Zone Controlled Induction Heating

Industrial Manufacturing and Processing

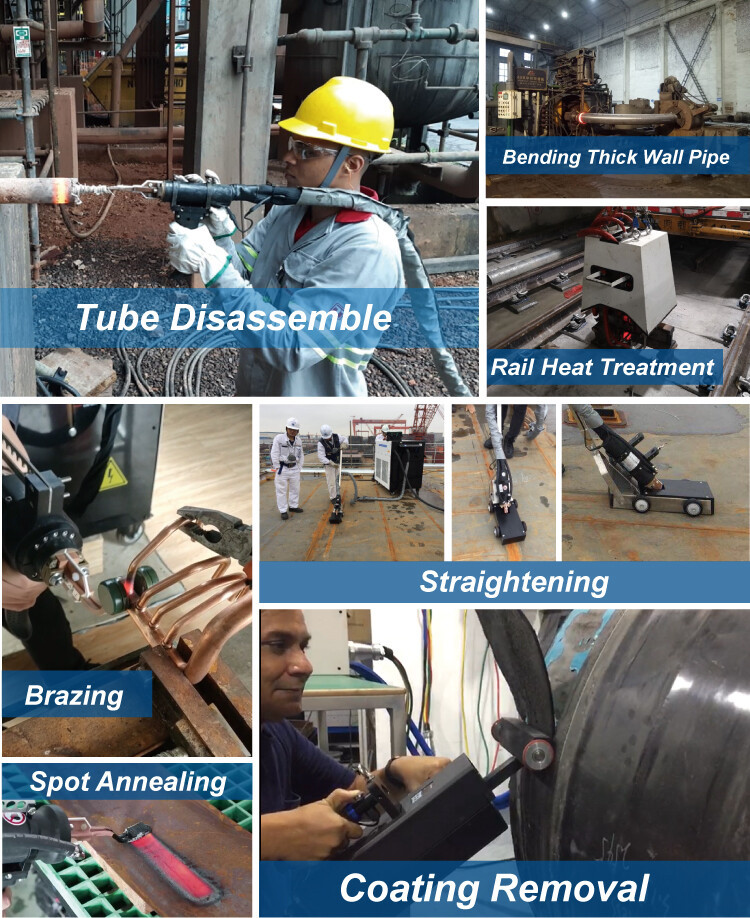

Zone controlled induction heating is important in making products. It controls heat in different zones for better efficiency. This saves energy and improves how things are made. Metalworking industries use it for forging, welding, and brazing. These jobs need even heat to keep quality high.

In food production, it helps with sterilizing and pasteurizing. This keeps food safe by heating it evenly. Farmers also use it for making tools and saving crops. By managing heat zones, it reduces waste and boosts productivity.

Automotive and Aerospace Applications

Cars and planes use this heating for shaping and forming parts. It helps shape metal without bending or breaking it. For welding, it gives the right heat for strong joints.

It is also used for treating metals to make them stronger. Processes like hardening protect surfaces from wear and rust. Composite materials also need this heat for better results.

Electronics and Semiconductor Industries

Electronics need very precise heat control during production. This heating helps make semiconductors by heating and cooling quickly. It improves the quality of the materials.

It also makes heating processes repeatable and easy to control. By using heat zones smartly, it saves energy and reduces waste. This makes it great for making top-quality electronics.

Advantages of Zone Controlled Induction Heating

Energy Efficiency and Cost Savings

Zone controlled induction heating saves energy by heating only needed areas. This reduces heat loss and ensures materials are heated efficiently. It turns up to 90% of energy into useful heat, making it better than older methods. Industries save money with shorter heating times and less electricity use.

With advanced systems, industries can save up to 50% on energy. This helps make manufacturing eco-friendly and lowers production costs.

Precision and Uniformity in Heating

This heating method controls temperatures exactly across different zones. Each zone works alone, allowing specific areas to be heated as needed. It provides repeatable and accurate heating, ensuring even heat across the material.

Independent zone control improves heating accuracy. Advanced systems adjust each zone for the right heat amount. This precision boosts product quality and reduces defects, making it great for industries needing reliable heating.

Reduced Material Waste and Enhanced Safety

Precise heat control prevents overheating, which can harm materials. By heating only necessary areas, this method cuts waste and uses energy wisely. It also makes industrial work safer.

Advanced systems keep performance steady, even in tough conditions. This reduces accidents and extends equipment life. Industries save on replacements and enjoy safer workplaces, making this technology essential for modern factories.

Zone-controlled induction heating helps industries with precise and efficient heating. It keeps temperatures steady and uses smart controls to save energy. This method is used in making semiconductors, studying materials, and managing waste. Its compact size and longer-lasting parts make it very useful. As industries grow, this technology will lead to new ideas and greener production.

FAQ

What are predefined temperature profiles in zone-controlled induction heating?

Predefined temperature profiles are preset heating plans. They help control heat accurately in different zones. This improves efficiency and keeps results steady for important tasks.

How does zone-controlled induction heating improve energy efficiency?

Zone-controlled induction heating focuses heat on needed areas. It avoids wasting energy by heating only specific zones. These zones follow preset plans for the best performance.

Why is zone-controlled induction heating suitable for critical applications?

This method manages heat with great accuracy. It keeps heat even and reliable, making it perfect for jobs needing strict heat control.

Please give us a message